Method for synthesizing metal-organic framework MIL-101-Cr with carboxylate as organic ligand and purifying method for MIL-101-Cr

A metal-organic framework, organic ligand technology, applied in the separation/purification of carboxylic acid compounds, organic chemical methods, preparation of organic compounds, etc., can solve the problems of serious sample loss, harsh conditions, difficult processing, etc. The effect of chemical production, few post-processing steps and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] (1) Preparation of terephthalate: Slowly add the alkali solution dropwise to the dimethylformamide (DMF) solution dissolved in terephthalic acid to obtain a white powder, dimethylformamide (DMF) and A mixed solution of equal volume of water is used to recrystallize the white powder to obtain terephthalate crystals;

[0042] Among them, the preferred salt of terephthalate is potassium hydrogen terephthalate, which is prepared by slowly adding potassium hydroxide solution dropwise into dimethylformamide (DMF) solution dissolved with terephthalic acid to obtain white Powder, dimethylformamide (DMF) and water equal volume mixed solution to recrystallize the white powder to obtain potassium hydrogen terephthalate crystals.

[0043] The molar ratio of potassium hydroxide and terephthalic acid is 1:1.

[0044] (2) Synthesis of samples: take chromium nitrate nonahydrate and potassium hydrogen terephthalate with a molar ratio of 0.8~1.2:1, adjust the pH value of the system to 3...

specific Embodiment

[0050] Specific examples: Ratio of experimental raw materials Potassium hydrogen terephthalate: chromium nitrate nonahydrate = 1:1 (molar ratio), which is the best ratio of organic ligands and metal ions in the synthesis of MIL-101-Cr. Acetic acid was selected as the mineralizer. Acetic acid with monodentate ligands can induce the terephthalate radicals of the bidentate ligands to coordinate with metal ions, which is beneficial to the nucleation of crystals. Acetic acid can also adjust the pH value of the solution. When the pH is 3~4, it is beneficial to the formation of MIL-101-Cr.

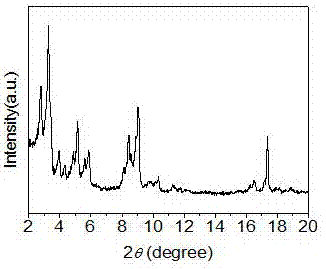

[0051] Temperature is a very critical factor for the hydrothermal reaction, and the selected temperatures are 140°C, 160°C and 180°C for 12 hours, as shown in Table 1 below. It was found that the temperature at 140°C was too low, and no solids were produced except the recrystallization of terephthalic acid; the temperature at 180°C was too high, and the solids produced were detected as amorphous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com