Method suitable for intermittent operation of biological activated carbon filter tank

A biological activated carbon, intermittent technology, applied in the field of operation, can solve problems such as delaying the production process of waterworks, less research on operating parameters, and microbial destruction of activated carbon, so as to be beneficial to microbial growth, absorption and degradation, and to promote rapid growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0028] A method suitable for intermittent operation of a biological activated carbon filter, comprising the following steps:

[0029] S1. When the biological activated carbon filter stops running, control the height of the water surface in the carbon pool so that it submerges the activated carbon in the carbon pool by 0.5-1.0m, drain the water in the carbon pool every 6-10 days, and then enter the water until it runs again;

[0030] S2. Backwash the biological activated carbon filter before it runs again; first air flushing, the intensity of air flushing is 5-10L / (m2·s), and the air flushing time is 3-5min; The impact intensity is 5-10L / (m2·s), the water impact intensity is 8-12L / (m2·s), and the time is 2-5min; the final water impact, the water impact intensity is 10-15L / (m2·s), the water impact The time is 5-10 minutes;

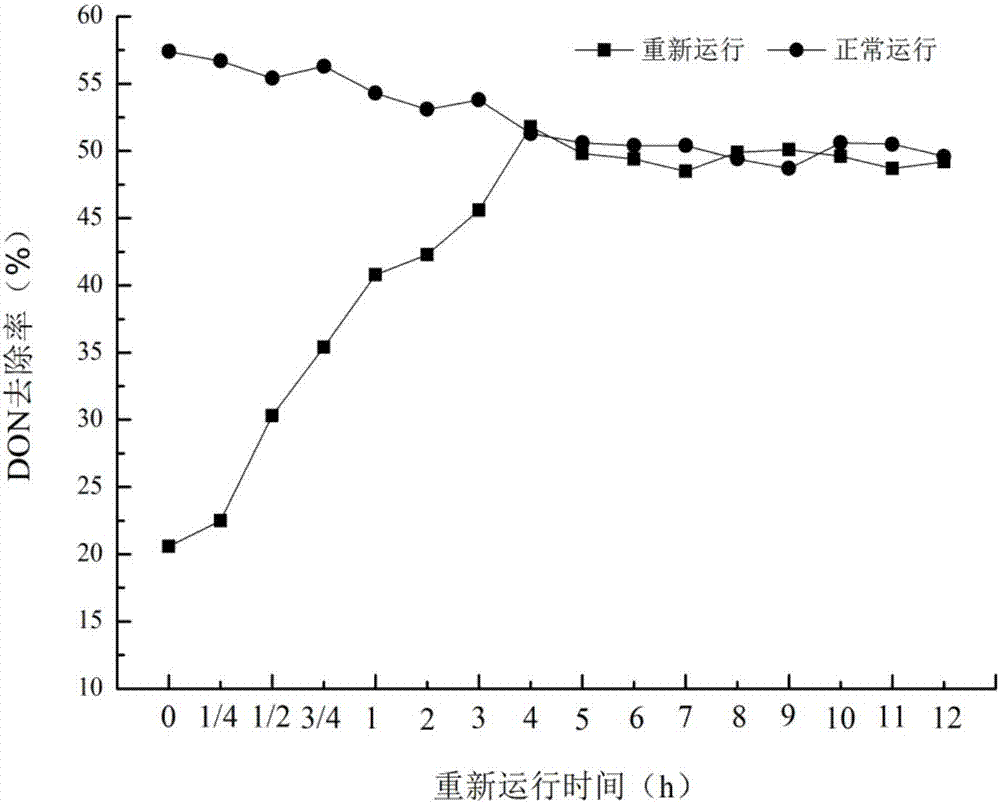

[0031] S3. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com