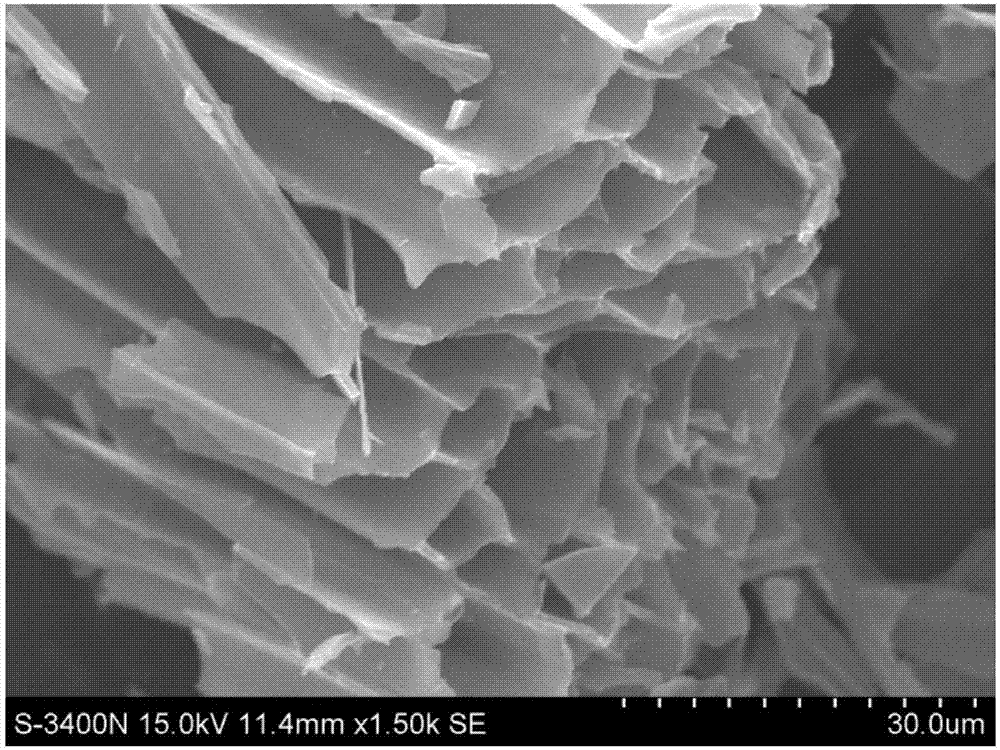

Preparation method of luffa sponge nitrogen-doped carbon nanomaterial

A nitrogen-doped carbon and nanomaterial technology, applied in nanocarbon and other directions, can solve the problems of high cost, harsh reaction conditions, insufficient raw materials, etc., and achieve the effects of saving industrial costs, simple preparation process and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of tianluo gluten nitrogen-doped carbon nano material specifically includes the following steps:

[0027] (1) Wash the Tianluojin after collecting, dry it in a muffle furnace at 100°C, dry for 12h, and grind it into a Tianluojin powder with a particle size of 100 mesh after drying;

[0028] (2) Prepare guanidine hydrochloride solution. The preferred mass ratio of Tianluojin and guanidine hydrochloride is 1:3. Add the ground Tianluojin into the solution for immersion. The immersion temperature is 20℃, and the immersion time is 4h-24h. Dry it at 30°C for use to prepare the precursor;

[0029] (3) Put the precursor in a tube furnace and calcine under the protection of nitrogen. The calcination time is 1h, the heating rate is 8°C / min, and the calcination temperature is 800°C to obtain the pre-carbonized product, and then cool down naturally;

[0030] (4) Prepare KOH solution, the preferred mass ratio of pre-carbonized product to KOH is 1:1, KOH solution concent...

Embodiment 2

[0034] A preparation method of tianluo gluten nitrogen-doped carbon nano material specifically includes the following steps:

[0035] (1) Wash the Tianluojin after collecting, dry it in a muffle furnace at 100°C, dry for 12h, and grind it into a Tianluojin powder with a particle size of 100 mesh after drying;

[0036] (2) Prepare a guanidine hydrochloride solution. The preferred mass ratio of Tianluojin and guanidine hydrochloride is 1:2. Add the ground Tianluojin into the solution for immersion. The immersion temperature is 60°C, the immersion time is 24h, and the temperature is 100%. Dry at ℃ for later use to prepare the precursor;

[0037] (3) Put the precursor in a tube furnace and roast under the protection of nitrogen. The roasting time is 1h, the heating rate is 8°C / min, and the roasting temperature is 300°C-800°C to obtain the pre-carbonized product, and then cool down naturally. ;

[0038] (4) Prepare the KOH solution, the preferred mass ratio of the pre-carbonized product t...

Embodiment 3

[0042] A preparation method of tianluo gluten nitrogen-doped carbon nano material specifically includes the following steps:

[0043] (1) Wash the Tianluojin after collecting, dry it in a muffle furnace at 100°C, dry for 12h, and grind it into a Tianluojin powder with a particle size of 100 mesh after drying;

[0044] (2) Prepare a guanidine hydrochloride solution. The preferred mass ratio of Tianluojin and guanidine hydrochloride is 1:1. Add the ground Tianluojin into the solution for immersion. The immersion temperature is 20℃, the immersion time is 24h, and the Dry it at ℃-200℃ for later use to prepare the precursor;

[0045] (3) Put the precursor in a tube furnace and roast it under the protection of nitrogen. The roasting time is 1h, the heating rate is 8°C / min, and the roasting temperature is 500°C to obtain the pre-carbonized product, and then cool down naturally;

[0046] (4) Prepare the KOH solution, the preferred mass ratio of the pre-carbonized product to KOH is 1:1, the KO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com