Vacuum adsorber for adsorbing breathable product

A vacuum adsorber and adsorber technology, which is applied to load hanging components, transportation and packaging, etc., can solve the problems of unstable adsorption, non-woven pollution, non-woven falling, etc., to increase adsorption firmness, reduce Contamination and drop prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

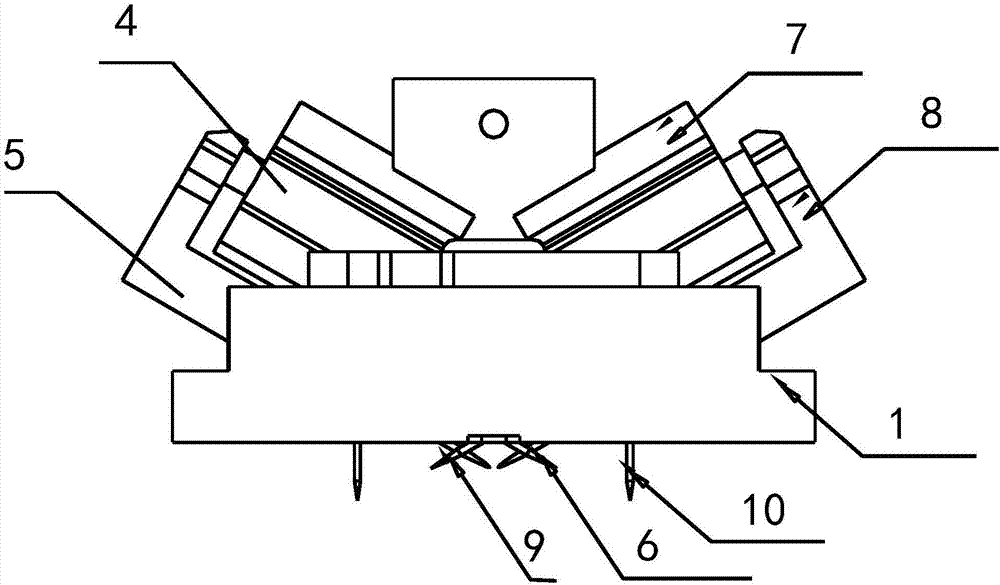

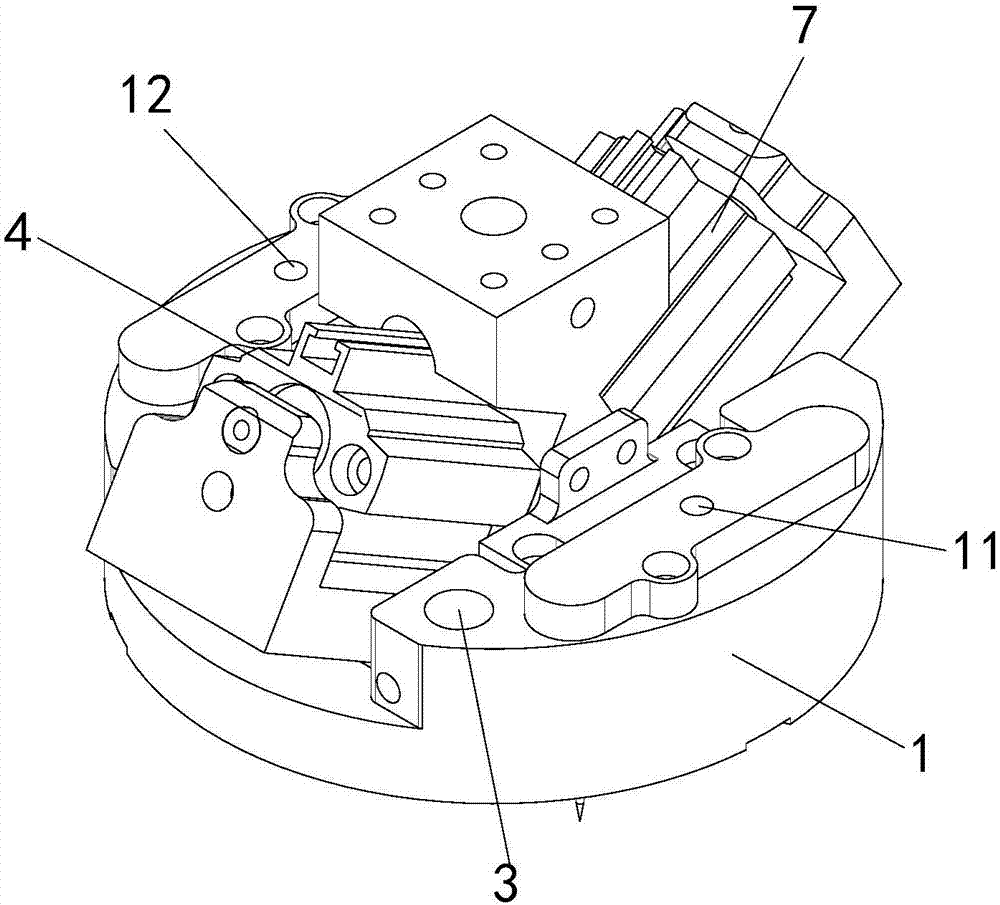

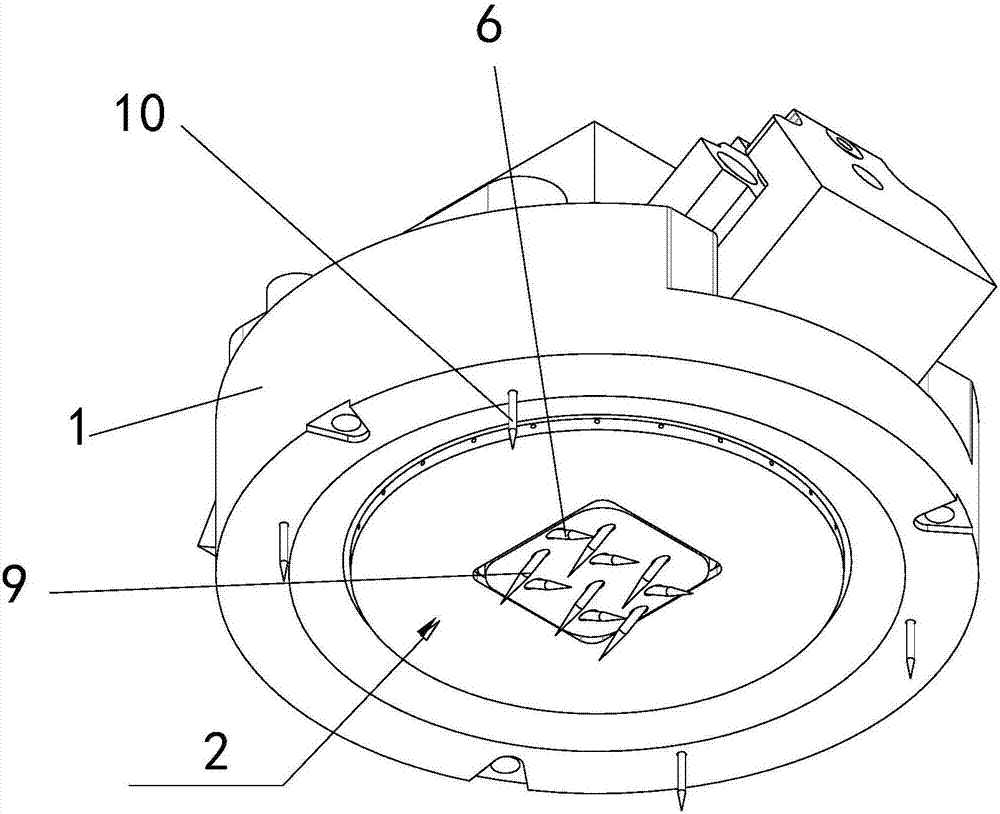

[0015] Such as Figure 1 to Figure 3 The shown vacuum adsorber for adsorbing gas-permeable products includes an adsorber body 1, a suspended suction cup vacuum generating device 2 is arranged at the bottom of the adsorber body 1, and the adsorber body 1 and the suspended suction cup vacuum generating device 2. Integral structure. Suspension-type non-contact suction cups can be directly purchased in the market. Therefore, the structure of the suspension-type suction cup vacuum generating device 2 is an open prior art, and will not be described here. 1 The top is provided with a vacuum suction port 3 communicating with the vacuum generating device 2 of the suspended suction cup. The adsorber body 1 is provided with a first cylinder 4, and the first cylinder 4 can be connected to the adsorber body through fasteners such as bolts. 1 fixed connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com