Resin structure, electronic component and electronic device using the same

A technology of electronic components and structures, applied in semiconductor/solid-state device parts, electrical components, devices for coating liquid on the surface, etc., can solve the problems of reduced heat dissipation, increased thermal resistance, and insufficient heat dissipation, and achieve High heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0057]

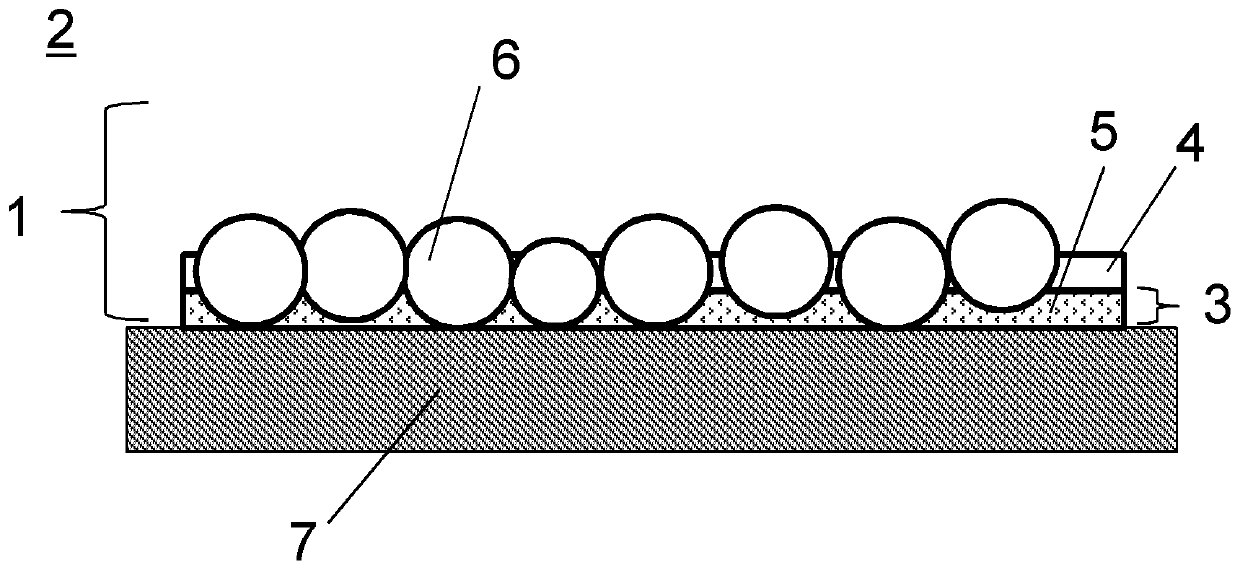

[0058] (a-1) of FIG. 1 is a cross-sectional view showing the cross-sectional structures of the resin structure 1 and the electronic component 2 according to the first embodiment. The resin structure 1 includes: a water-based paint layer 3 provided on a heating element 7 , and a resin layer 4 provided on the water-based paint layer 3 . The water-based paint layer 3 includes a water-based paint 5 and spherical fillers 6 . The spherical filler 6 is characterized in that at least a part of it exists in the water-based paint layer 3, and for more than 80% of all the fillers 6, the long axis of the filler 6 passing through the center of gravity has the water-based paint 5 with the water-based paint layer 3. The length is 1.7 times or more of the total thickness of the thickness and the thickness of the thermosetting resin of the resin layer 4 . It should be noted that the far-infrared emissivity of the filler 6 is not less than 0.8, and the average aspect ratio of the ma...

Embodiment approach 2

[0098]

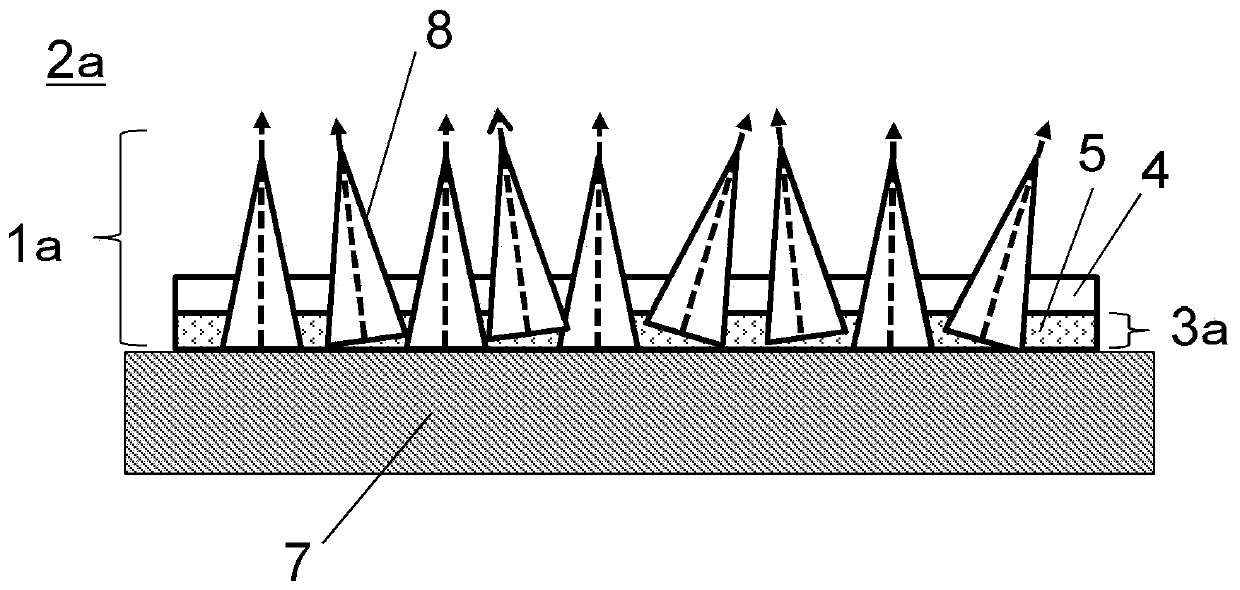

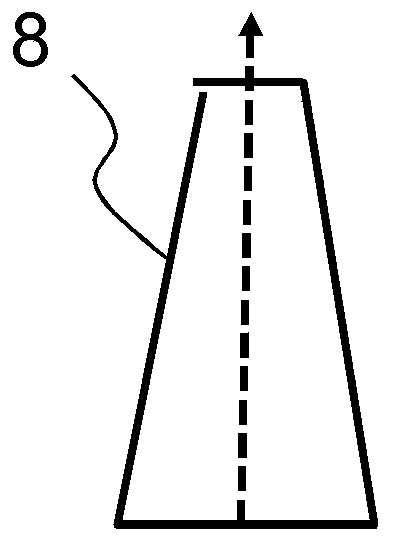

[0099] (a-2) of FIG. 1 is sectional drawing which shows the structure of the resin structure 1a of Embodiment 2, and the electronic component 2a. The resin structure 1 a of the second embodiment differs from the resin structure of the first embodiment in that the shape of the filler 8 used is not spherical but conical. This resin structure 1a includes a water-based paint layer 3a provided on a heat generating element 7, and a resin layer 4 provided on the water-based paint layer 3a. The water-based paint layer 3 a includes a water-based paint 5 and fillers 8 in the shape of pyramids or polyhedrons. The feature of this pyramidal or polyhedral filler 8 is that at least a part of it exists in the water-based paint layer 3a, and for more than 80% of all the fillers 8, the long axis passing through the center of gravity of the filler 8 has the water-based paint layer 3a. A length equal to or greater than 1.7 times the total thickness of the thickness of the coating mate...

Embodiment 1~4

[0156] According to the procedures described above in and the conditions in Table 1, the heat dissipation evaluation element 10 and the heat dissipation evaluation jig were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com