Multi-anti-corrosion protection construction method of sea steel cylinder revetment structure

A construction method and multi-layer anti-corrosion technology, applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of inability to guarantee the safety hazards of steel structures in the sea, permanent steel cylinder revetment structures, etc., to prevent interference , to ensure waterproof requirements, to reduce the effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

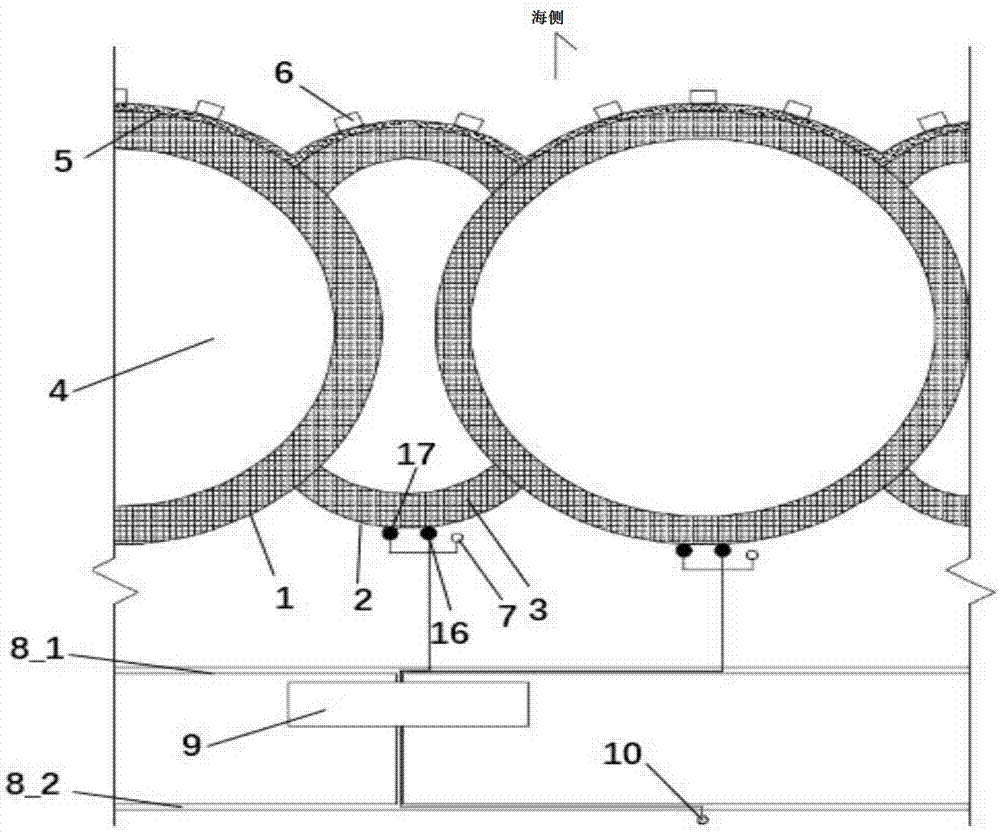

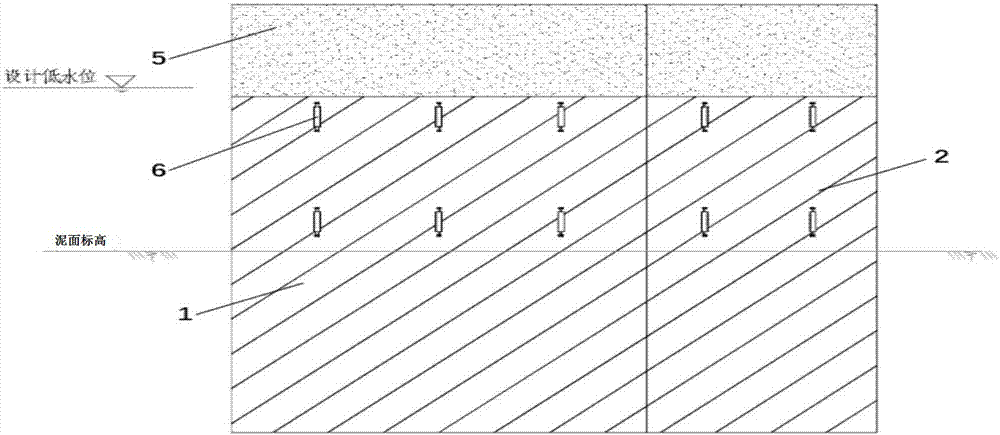

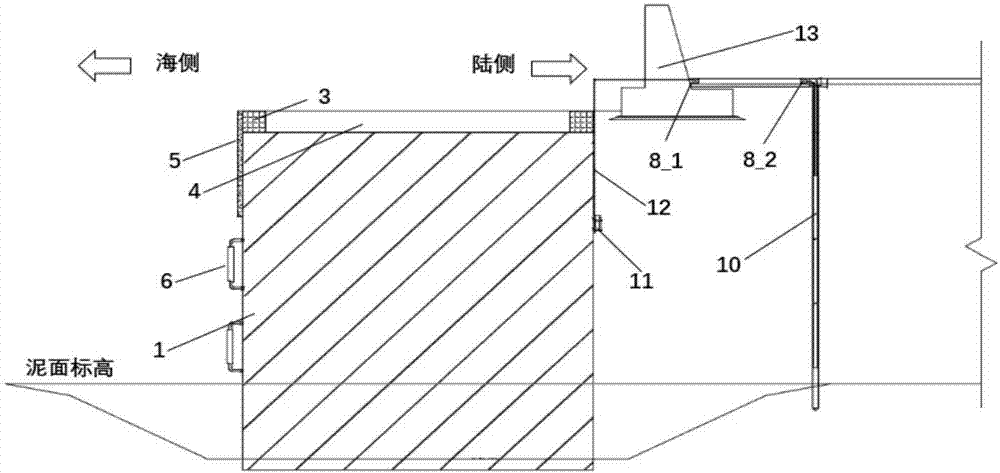

[0045] (1) During the process of processing the steel cylinder 1 and the steel auxiliary grid 2 of the steel cylinder revetment structure, the outer wall and the inner wall of the steel cylinder 1 and the steel auxiliary grid 2 are coated with anti-corrosion paint; the steel cylinder 1 and the steel auxiliary grid on the sea side The thickness of the anti-corrosion coating on the outer wall of the steel auxiliary grid 2 is 1.5 times the thickness of the anti-corrosion coating on the outer wall of the steel cylinder 1 and the steel auxiliary grid 2 on the land side and the thickness of the anti-corrosion coating on the inner wall of the steel cylinder 1 and the steel auxiliary grid 2;

[0046] (2) A plurality of steel cylinders 1 and steel auxiliary grids 2 are connected at sea according to the design requirements to form a steel cylinder revetment structural system;

[0047] (3) Fill each steel cylinder 1 and steel auxiliary grid 2 with medium coarse sand to a distance of 2m fr...

Embodiment 2

[0057] (1) During the process of processing the steel cylinder 1 and the steel auxiliary grid 2 of the steel cylinder revetment structure, the outer wall and the inner wall of the steel cylinder 1 and the steel auxiliary grid 2 are coated with anti-corrosion paint; the steel cylinder 1 and the steel auxiliary grid on the sea side The thickness of the anti-corrosion coating on the outer wall of the steel auxiliary grid 2 is 1.5 times the thickness of the anti-corrosion coating on the outer wall of the steel cylinder 1 and the steel auxiliary grid 2 on the land side and the thickness of the anti-corrosion coating on the inner wall of the steel cylinder 1 and the steel auxiliary grid 2;

[0058] (2) A plurality of steel cylinders 1 and steel auxiliary grids 2 are connected at sea according to the design requirements to form a steel cylinder revetment structural system;

[0059] (3) Fill each steel cylinder 1 and steel auxiliary grid 2 with medium coarse sand to a distance of 1.5m ...

Embodiment 3

[0069] (1) During the process of processing the steel cylinder 1 and the steel auxiliary grid 2 of the steel cylinder revetment structure, the outer wall and the inner wall of the steel cylinder 1 and the steel auxiliary grid 2 are coated with anti-corrosion paint; the steel cylinder 1 and the steel auxiliary grid on the sea side The thickness of the anti-corrosion coating on the outer wall of the steel auxiliary grid 2 is 1.5 times the thickness of the anti-corrosion coating on the outer wall of the steel cylinder 1 and the steel auxiliary grid 2 on the land side and the thickness of the anti-corrosion coating on the inner wall of the steel cylinder 1 and the steel auxiliary grid 2;

[0070] (2) A plurality of steel cylinders 1 and steel auxiliary grids 2 are connected at sea according to the design requirements to form a steel cylinder revetment structural system;

[0071] (3) Fill each steel cylinder 1 and steel auxiliary grid 2 with medium coarse sand to a distance of 2m fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com