Molten steel slag rolling modification treatment device and method

A processing device and steel slag rolling technology, applied in the direction of recycling technology, etc., can solve problems such as the inability to effectively improve the hydraulic cementation of steel slag, improve volume stability and hydraulic cementation, and reduce the content of free calcium oxide. , the effect of simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

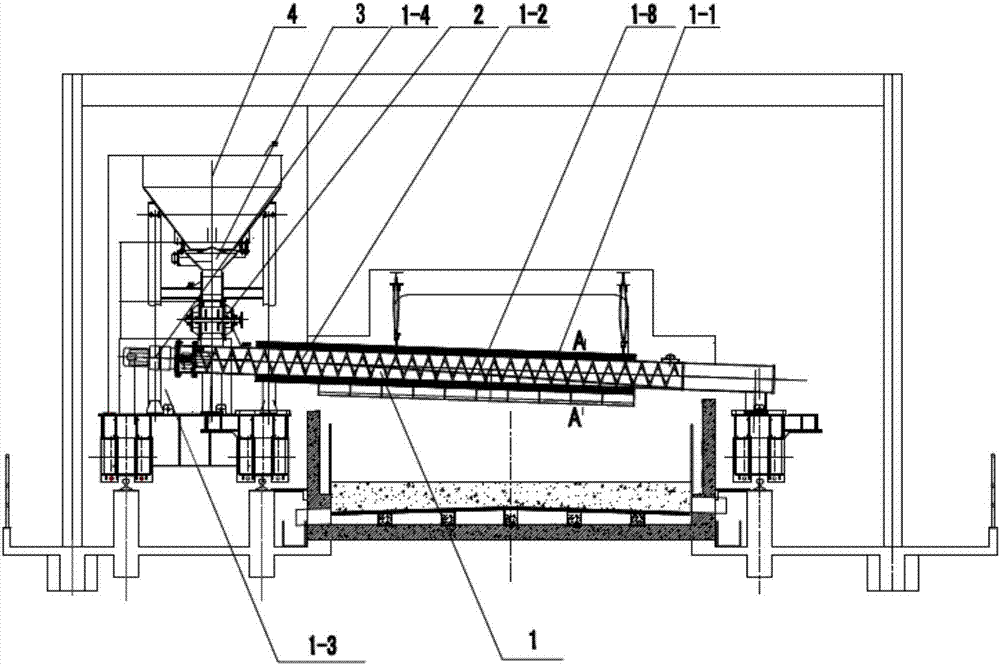

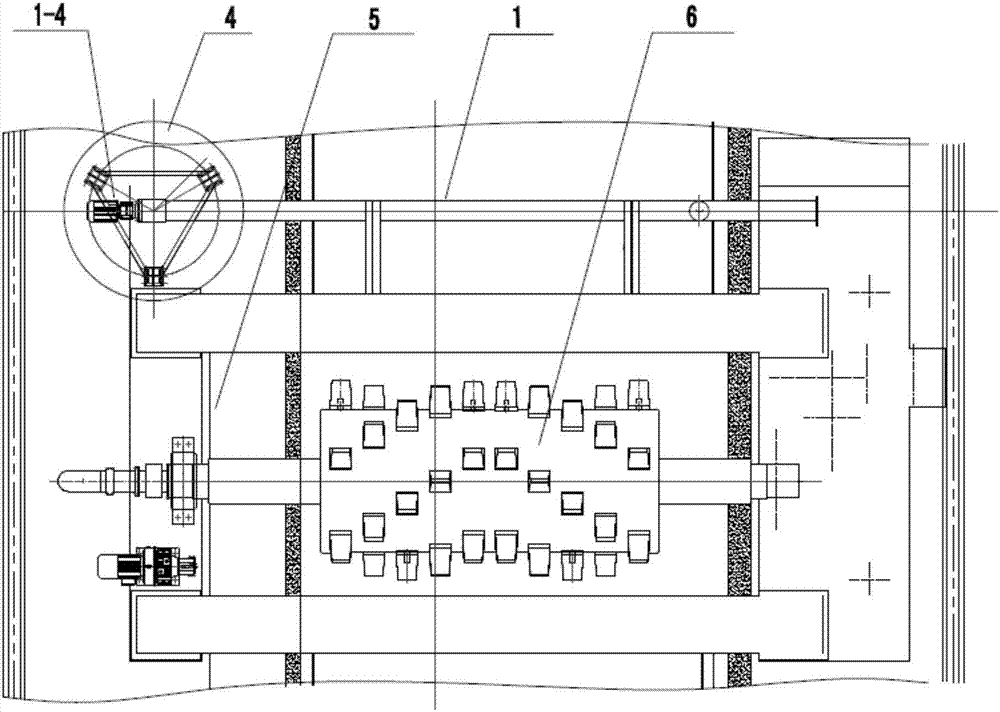

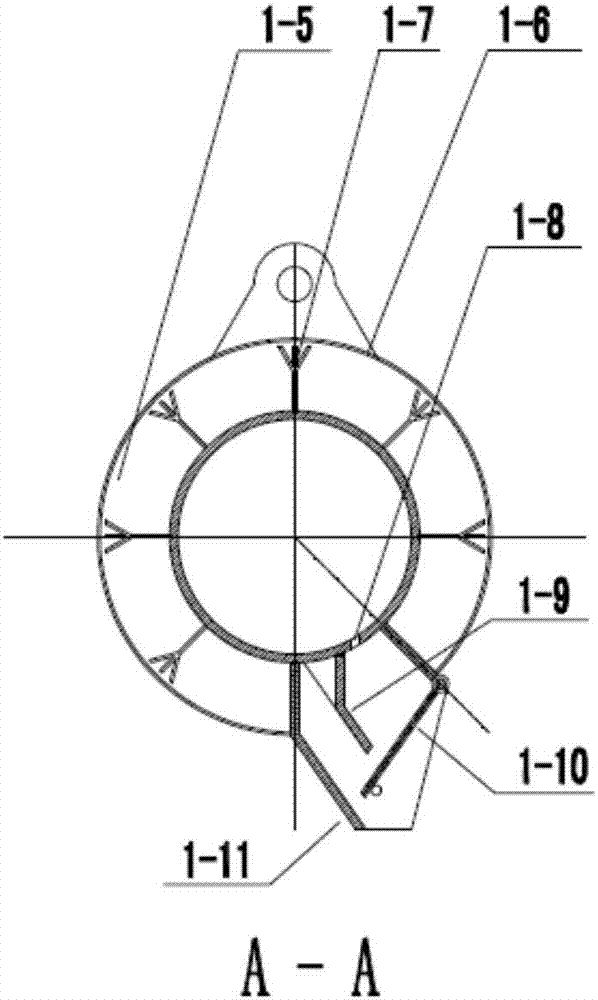

[0041] like figure 1 , 2 , 3 is a structural diagram of a rolling modification treatment device for molten steel slag according to the present invention, which includes a screw feeding device 1 , a rotary feeding valve 2 , a pulse feeding device 3 , and a silo 4 . The modified material is placed in the silo 4, the pulse feeding device 3 is connected to the bottom of the silo 4, the rotary feeding valve 2 is connected to the bottom of the pulse feeding device 3, and the screw feeding valve 2 is installed below the rotary feeding valve 2. Device 1, the modified material in the silo 4 is sent into the screw feeding device 1 through the pulse feeding device 3 and the rotary feeding valve 2; and the modified material is spread on the slag bed through the screw feeding device 1, wherein, the screw The feeding device 1, the rotary feeding valve 2, the pulse feeding device 3, and the silo 4 are located on the rolling crushing trolley 5, and move back and forth together with the rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com