Bacillus natto with MK-7 production capacity and application of bacillus natto

A technology of Bacillus natto and Bacillus bean, which is applied in the field of bioengineering, can solve the problems of increasing atherosclerosis and blood pressure, and achieve the effect of improving osteoporosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

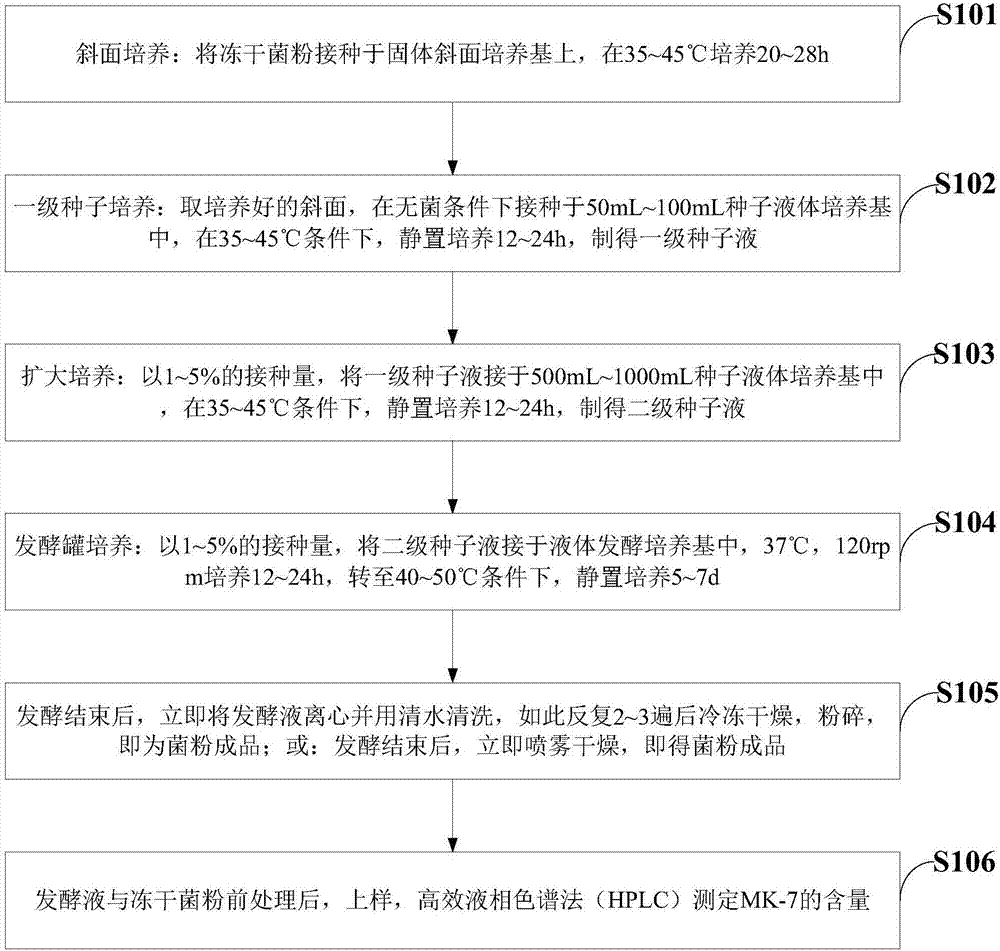

Method used

Image

Examples

Embodiment 1

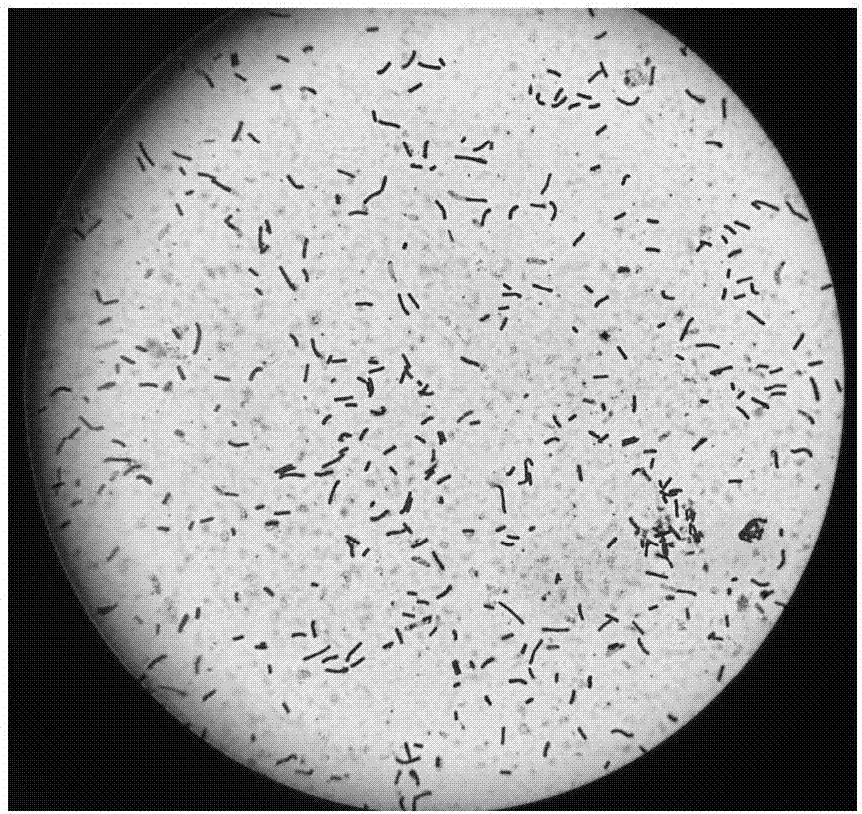

[0043] Primary screening of Bacillus natto

[0044] 1 Materials and methods:

[0045] 1.1 Experimental strains, Bacillus natto BLCC1-0048, Bacillus natto BLCC1-0053, Bacillus natto BLCC1-0054;

[0046] 1.2 Fermentation medium and culture conditions:

[0047] Two media formulations:

[0048] Seed medium: glucose 0.2%, peptone 1%, beef extract 0.5%, NaCl 0.5%, pH 7.2-7.4;

[0049] Fermentation medium: yeast extract 5%, glycerol 5%, peptone 10%, K 2 HPO 4 0.06%;

[0050] Culture conditions: culture on a shaker at 37°C for 24h, with a rotation speed of 120rpm, and then culture at 45°C for 5 days.

[0051] 1.3 After the fermentation is finished, the fermentation broth and bacteria are separated by centrifugation, and the bacteria are freeze-dried.

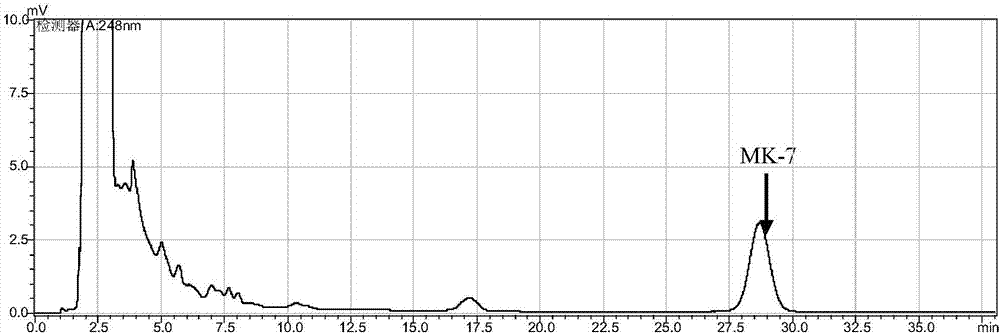

[0052] 1.4 Determination of MK-7 content in fermentation cells and fermentation broth:

[0053] Weigh an appropriate amount of freeze-dried bacteria (about 25 mg), extract it with a mixed solution of chloroform: n-hexane = 2:1 ...

Embodiment 2

[0063] Determination of MK-7 content in Bacillus natto fermented for 6 days under different medium conditions:

[0064] 1 Materials and methods:

[0065] 1.1 Experimental strain Bacillus natto strain BLCC 10053;

[0066] 1.2 Fermentation medium and culture conditions:

[0067] Three basal media formulations:

[0068] N1: Glycerol 3%, Peptone 10%, NaCl 0.5%, K 2 HPO 4 0.02%, pH 7.0-7.2N2: glucose 0.2%, yeast extract 0.5%, peptone 1.0%, sodium chloride 0.5%, pH 7.0-7.2N3: yeast extract 2.5%, glycerol 2.5%, peptone 9.5% , K 2 HPO 4 0.03%, pH 7.0-7.2 Culture conditions:

[0069] The specific experimental scheme is shown in Table 2. The activated Bacillus natto was inserted into the seed medium, cultured on a shaking table at 42°C for 16 hours, transferred to the fermentation medium with an inoculum size of 5%, and cultured on a shaking table at 37°C for 1 day. Transfer to a 45°C incubator for static culture for 5 days.

[0070] 1.3 After the fermentation is finished, th...

Embodiment 3

[0079] Content of Bacillus natto MK-7 under different fermentation time conditions:

[0080] 1 Materials and methods:

[0081] 1.1 Experimental strain Bacillus natto strain BLCC 10053;

[0082] 1.2 Fermentation medium and culture conditions;

[0083] Seed medium N2: glucose 0.2%, peptone 1.0%, sodium chloride 0.5%, yeast extract 0.5%, pH 7.0-7.2; fermentation medium N1: peptone 10%, glycerol 3%, NaCl 0.5%, K 2 HPO 4 0.02%, pH7.0-7.2.

[0084] The activated Bacillus natto was inserted into the seed medium, cultured on a shaker at 42°C for 16 hours, transferred to the fermentation medium at an inoculum size of 5%, cultured on a shaker at 37°C for 1 day, and then transferred to an incubator at 45°C for standing Culture 3d, 4d, 5d, 6d, 7d.

[0085] 1.3 After the fermentation is finished, the fermentation product and bacteria are separated by centrifugation, and the bacteria are freeze-dried.

[0086] 1.4 Determination of MK-7 content in fermented bacteria and fermented liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com