Inorganic gel profile control agent suitable for thermal oil recovery and use method thereof

A thermal oil recovery and inorganic gel technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of losing the effect of profile control, the difficulty of thermal oil recovery profile control, and the difficulty of profile control technology to exert corresponding effects. , to achieve the effect of enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

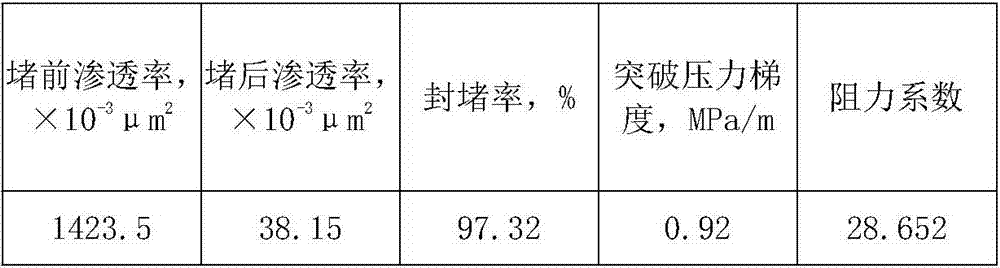

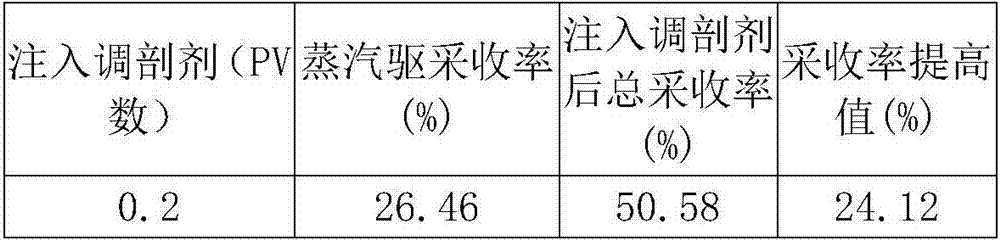

[0026] The plugging effect of the profile control agent was evaluated by the indoor core test method, as follows:

[0027] 1. Preparation of profile control agent:

[0028] Firstly, the prepared water is subjected to oxygen exposure treatment, and the prepared water adopts simulated oilfield sewage to reduce the oxygen content in the prepared water to below 3mg / L; at room temperature, add mixed polyacrylamide, organic chromium system, citric acid to the prepared water in sequence aluminum, sodium fluorosilicate, and stirred at a constant speed for 2 hours to obtain a gel emulsion; adding the inorganic blocking agent to the gel emulsion and stirred for 1.5 hours to obtain a high-temperature resistant inorganic profile control agent.

[0029] 2. Water for dosing, adjust the salinity by adding NaCl like distilled water, and the final profile control salinity is 3000mg / L.

[0030] 3. The specific application dosage is:

[0031] In the profile control agent, the mass ratio of ino...

Embodiment 2

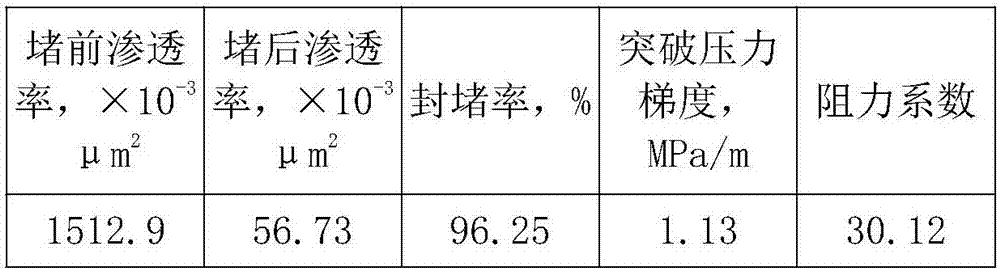

[0056] 1. Preparation method of profile control agent:

[0057] Firstly, the prepared water is subjected to oxygen exposure treatment, and the prepared water adopts simulated oilfield sewage to reduce the oxygen content in the prepared water to below 3mg / L; at room temperature, add mixed polyacrylamide, organic chromium system, citric acid to the prepared water in sequence aluminum, sodium fluorosilicate, and stirred at a constant speed for 3 hours to obtain a gel emulsion; adding the inorganic blocking agent to the gel emulsion and stirred for 2 hours to obtain a high-temperature resistant inorganic profile control agent.

[0058] 2. Water for dosing, adjust the salinity by adding NaCl like distilled water, and the final profile control salinity is 8000mg / L.

[0059] 3. The specific application dosage is:

[0060] In the profile control agent, the mass ratio of inorganic plugging agent is 15%, and the mass ratio of gel emulsion is 85%. The gel emulsion includes 0.15% of part...

Embodiment 3

[0085] 1. Preparation method of profile control agent:

[0086] Firstly, the prepared water is subjected to oxygen exposure treatment, and the prepared water adopts simulated oilfield sewage to reduce the oxygen content in the prepared water to below 3mg / L; at room temperature, add mixed polyacrylamide, organic chromium system, citric acid to the prepared water in sequence aluminum and sodium fluorosilicate, and stirred at a constant speed for 2 hours to obtain a gel emulsion; adding the inorganic blocking agent to the gel emulsion and stirred for 1 hour to obtain a high-temperature resistant inorganic profile control agent.

[0087] 2. Water for dosing, adjust the salinity by adding soluble salts like distilled water, and the final profile control salinity is 100000mg / L.

[0088] 3. The specific application dosage is:

[0089] In the profile control agent, the mass ratio of inorganic plugging agent is 12.5%, and the mass ratio of gel emulsion is 87.5%. The gel emulsion inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com