Anti-skid material and application thereof

A non-slip, raw material technology, applied in the field of anti-slip materials, to achieve the effect of preventing the human body from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

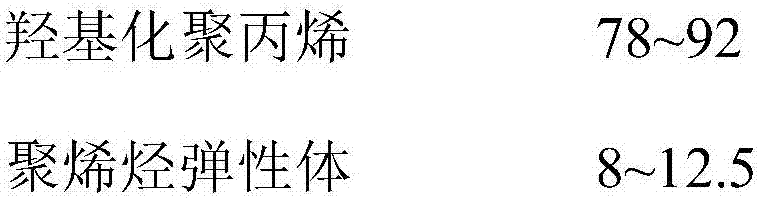

[0030] A kind of anti-skid material, described anti-skid material comprises following raw material by weight part:

[0031]

[0032] The bridging agent is (2-tert-butylperoxyisopropyl)-3-isopropenylbenzene.

[0033] The bridging aid is triallyl isocyanurate.

[0034] Described active agent selects stearic acid for use.

[0035] The filler is selected from talcum powder.

Embodiment 2

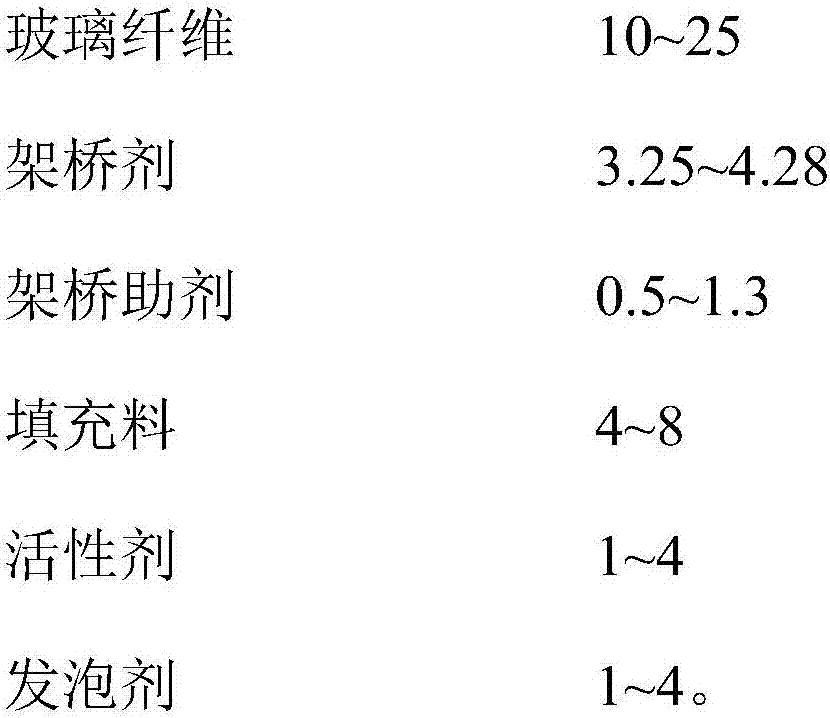

[0037] A kind of anti-skid material, described anti-skid material comprises following raw material by weight part:

[0038]

[0039] The bridging agent is (2-tert-butylperoxyisopropyl)-3-isopropenylbenzene.

[0040] The bridging aid is triallyl isocyanurate.

[0041] Described active agent selects zinc stearate for use.

[0042] The filler is selected from a mixture of diatomaceous earth and pumice powder.

Embodiment 3

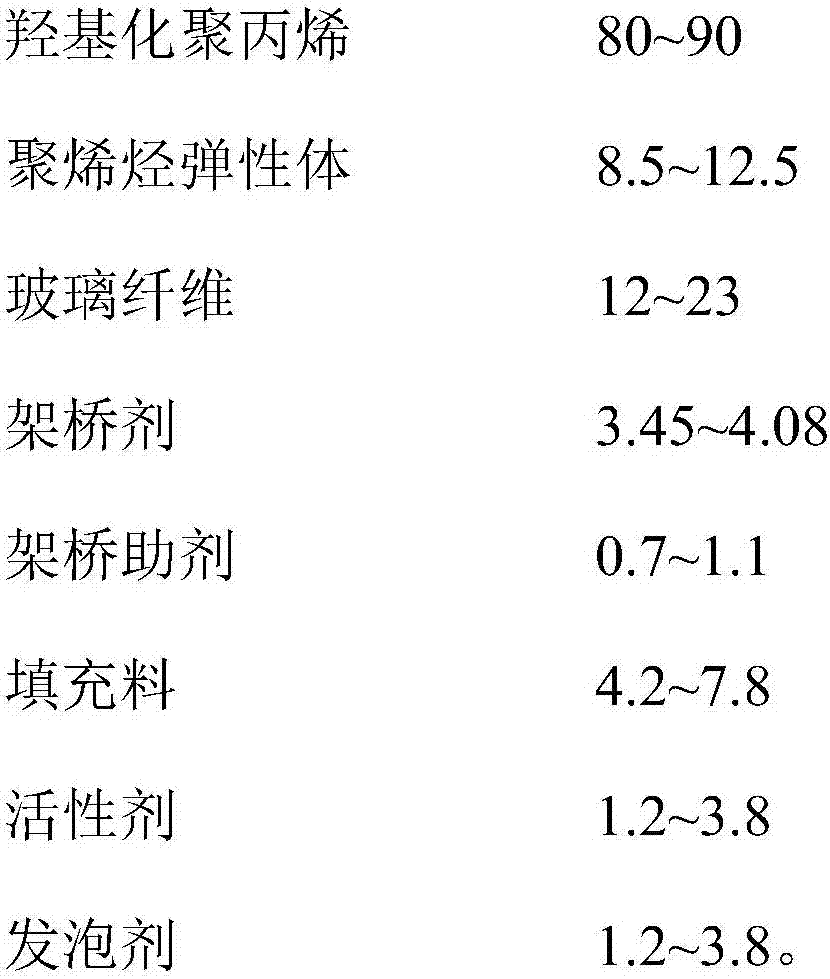

[0044] A kind of anti-skid material, described anti-skid material comprises following raw material by weight part:

[0045]

[0046]

[0047] The bridging agent is (2-tert-butylperoxyisopropyl)-3-isopropenylbenzene.

[0048] The bridging aid is triallyl isocyanurate.

[0049] Described active agent selects stearic acid and zinc stearate for use.

[0050] The filler is selected from the mixture of talcum powder, heavy calcium carbonate and light calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abrasion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com