Preparation method and application of ochratoxin metal organic skeleton-molecular imprinting compounded separation medium

A metal-organic framework and ochratoxin technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of high price, easy to be affected by sample matrix, pH, solvent, salt concentration, etc., and low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

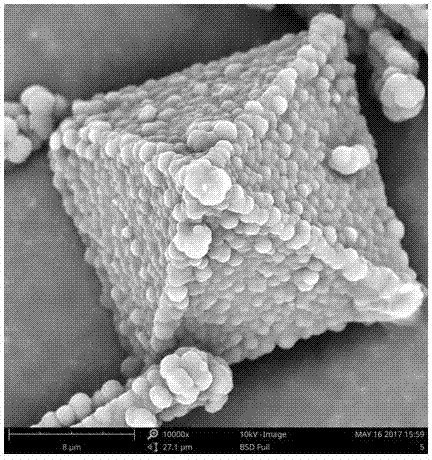

[0025] Add 1.0 mmol of 1-hydroxy-4-p-tolylaminoanthraquinone into a three-neck flask of absolute ethanol containing 1.5 g of activated metal-organic frameworks, 150 mL, and then add 5.0 mmol of butyl methacrylate, 30 mmol of ethylene glycol dimethyl Acrylate and 2.5% initiator azobisisobutyronitrile, ultrasonicated for 5 minutes, until the solution was evenly mixed, mechanically stirred (rotating speed 200 r min -1 ), placed in a constant-temperature oil bath at 75°C, reacted for 5 hours, raised to 90°C and matured for 1 hour, then sucked and dried to obtain an organic framework-molecularly imprinted complex containing a substitute template. The complex was washed with methanol / acetic acid (4:1, v / v) and methanol until no template molecules were washed out. After air-drying, vacuum-dry at 40°C for 48 hours to obtain an organic framework-molecular imprinted complex.

Embodiment 2

[0027] Add 1.0 mmol 1-hydroxy-4-p-tolylaminoanthraquinone to a 150 mL three-neck flask of absolute ethanol containing 1.5 g of activated metal-organic framework, then add 7.0 mmol butyl methacrylate, 30 mmol ethylene glycol dimethyl Acrylic acid ester and 2.5% initiator azobisisobutyronitrile, ultrasonic 5min, until the solution is mixed evenly, mechanical stirring (speed 200 r min -1 ), placed in a constant-temperature oil bath at 75°C, reacted for 5 hours, raised to 90°C and matured for 1 hour, and then filtered and dried to obtain an organic framework-molecularly imprinted complex containing a substitute template. The complex was washed with methanol / acetic acid (4:1, v / v) and methanol until no template molecules were washed out. After air-drying, vacuum-dry at 40°C for 48 hours to obtain an organic framework-molecular imprinted complex.

Embodiment 3

[0029] Add 1.0 mmol of 1-hydroxy-4-p-tolylaminoanthraquinone into a 150 mL three-neck flask of absolute ethanol containing 1.5 g of the activated metal-organic framework, then add 7.0 mmol of butyl methacrylate and 15 mmol of ethylene glycol Dimethacrylate and 2.5% initiator azobisisobutyronitrile, ultrasonicated for 5 minutes, until the solution was evenly mixed, mechanically stirred (rotating speed 200 r min -1 ), placed in a constant-temperature oil bath at 75°C, reacted for 5 hours, raised to 90°C and matured for 1 hour, and then filtered and dried to obtain an organic framework-molecularly imprinted complex containing a substitute template. The complex was washed with methanol / acetic acid (4:1, v / v) and methanol until no template molecules were washed out. After air-drying, vacuum-dry at 40°C for 48 hours to obtain an organic framework-molecular imprinted complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com