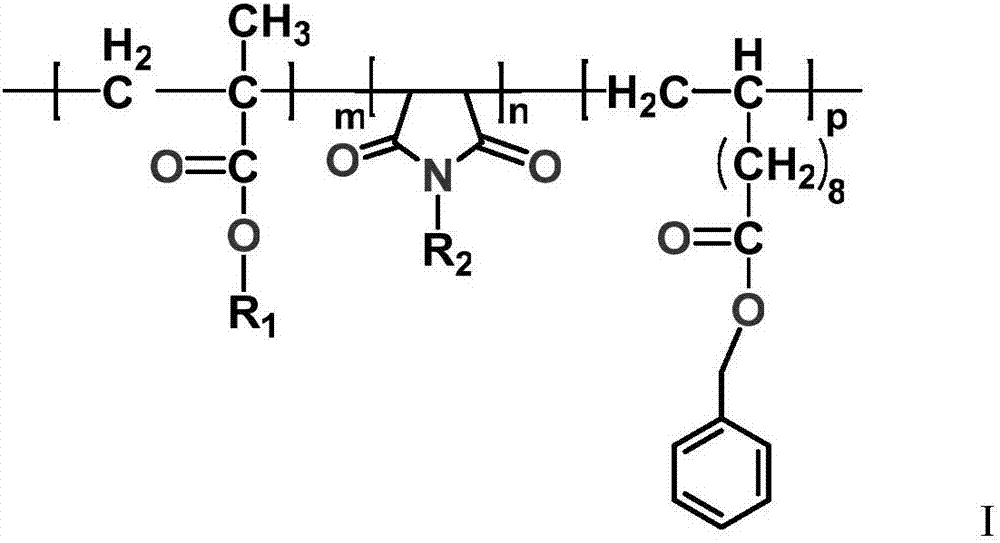

Aromatic ternary polymer diesel pour point depressant and preparation method thereof

A technology of ternary polymer and diesel pour point depressant, which is applied in the field of pour point depressant, can solve the problems such as the filter depressant effect or the filter depressant effect does not decrease but rises, cannot adapt to petroleum products, and the pour point depressant has a single component, etc., to achieve Increased shear performance, improved cold filter point, improved condensation point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

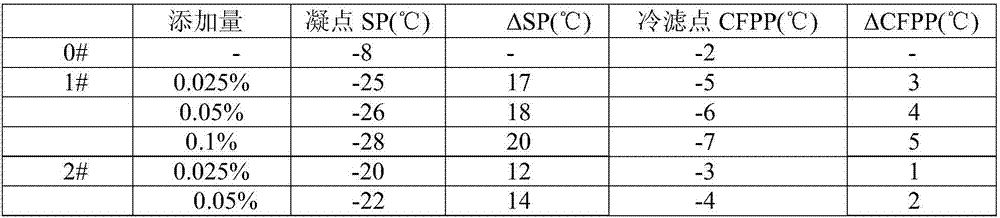

Examples

Embodiment 1

[0026] (1) Add 21.44g (0.1mol) tetradecyl alcohol, 0.309g polymerization inhibitor hydroquinone, and 50ml solvent toluene to a three-necked flask equipped with a condenser, a water separator, and a magnetic stirring device, and heat up to 55° C. Dissolve all myristyl alcohol in toluene, then quickly add 12.91g (0.15mol) of methacrylic acid and 0.481g of catalyst p-toluenesulfonic acid into the three-necked flask, and raise it to 125°C. The water generated by the esterification reaction will As the reaction temperature rises, the copolymer formed with toluene is distilled out, and enters the water separator after being condensed. React at this temperature for 5 hours. When it is observed that the amount of desorbed water is equivalent to the theoretical value, the system is in a yellow-brown transparent liquid state, and the reaction is terminated. After the reaction is completed, the obtained reaction liquid is distilled off the solvent toluene under reduced pressure when the ...

Embodiment 2

[0030] The difference from Example 1 is that the addition of 4.27g (0.02mol) tetradecylamine, 0.177g catalyst p-toluenesulfonic acid in step (3) is replaced by adding 4.83g (0.02mol) hexadecylamine, 0.185g catalyst p-toluene sulfonic acid.

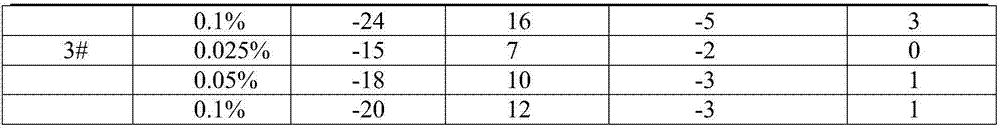

Embodiment 3

[0032]The difference from Example 1 is that the addition of 4.27g (0.02mol) tetradecylamine, 0.177g catalyst p-toluenesulfonic acid in step (3) is replaced by adding 5.39g (0.02mol) octadecylamine, 0.194g catalyst p-toluene sulfonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com