Optical component, optical device and adjustment method for optical device

A technology for optical components and optical devices, applied in optical components, optics, instruments, etc., can solve the problems of limited duration and continuous effect, waste of resources, etc., and achieve the effect of improving fogging and easy rolling inside the enclosed space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

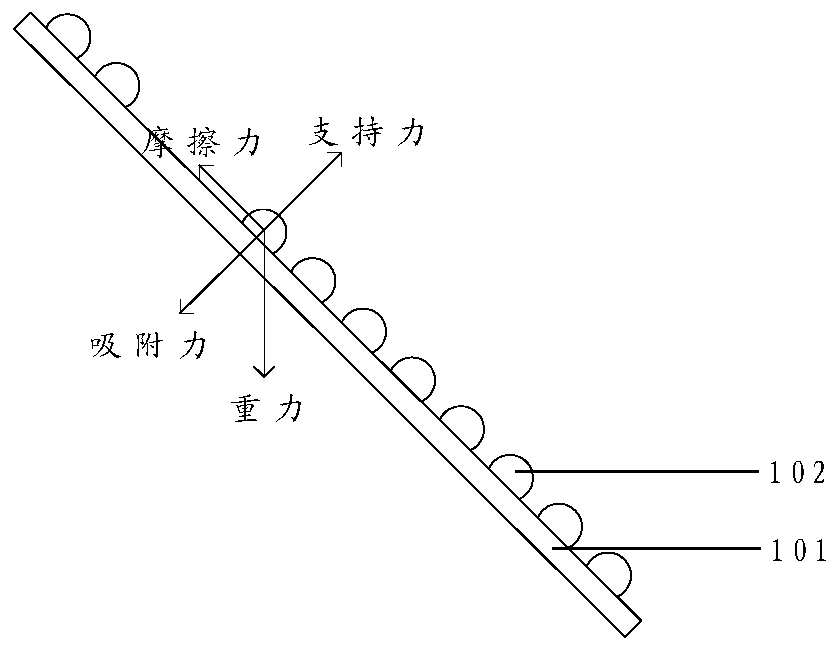

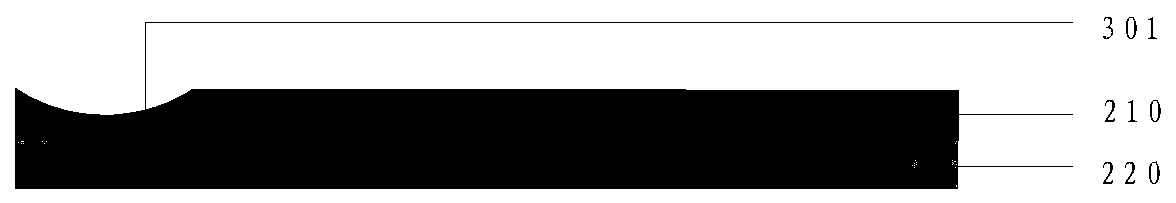

[0053] see figure 2 , Embodiment 1 of the present invention provides an optical component, including: a conversion film layer 210 and an excitation film layer 220 on the conversion film layer, wherein, the conversion film layer is performed according to specific parameters of the excitation film layer Reversible switch between hydrophilic and hydrophobic states.

[0054]Preferably, when the characteristic parameter of the excitation film layer satisfies a preset condition, the conversion film layer undergoes a reversible switch between a hydrophilic state and a hydrophobic state. Wherein, the characteristic parameters of the excitation film layer include: temperature, light intensity, pH, and electric field intensity.

[0055] Wherein, the conversion film layer 210 is a reversible superhydrophobic hydrophilic conversion film layer, and the excitation film layer is determined according to the response characteristic parameters of the conversion film layer. That is, the formi...

Embodiment 2

[0065] see Figure 5 , an embodiment of the present invention provides a method for preparing an optical component, the method comprising:

[0066] S501, forming an excitation film layer for the excitation conversion film layer to perform reversible conversion between hydrophilic state and hydrophobic state;

[0067] S502. Form a conversion film layer on the excitation film layer by a sol-gel method, a template method, a self-assembly method, or a chemical etching method.

[0068] If the conversion film layer is a temperature-responsive film, a surface-induced atom transfer radical polymerization method can be used to prepare a temperature-responsive polymer film on the substrate. By controlling the surface roughness, within a narrow temperature range, Thereby, the reversible transition between superhydrophilic and superhydrophobic of the switching membrane layer is realized.

Embodiment 3

[0070] see Image 6 , Embodiment 3 of the present invention provides an optical device, including: the optical assembly 610 and the control module 620 described in Embodiment 1; wherein,

[0071] The optical component 610 includes: a conversion film layer and an excitation film layer;

[0072] The control module 620 is configured to adjust the characteristic parameters of the excitation film layer according to the received message, so that the conversion film layer undergoes a reversible switch between hydrophilic state and hydrophobic state.

[0073] Specifically, to adjust the characteristic parameters of the excitation film layer, the control module 620 is specifically used to:

[0074] An electric signal is sent to the excitation film layer, so that the characteristic parameter of the excitation film layer reaches a preset conversion threshold.

[0075] Among them, according to the difference of the conversion film layer, it can be divided into the following situations: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com