Cutting device for broad beans

A cutting device and broad bean technology, applied in metal processing, food processing, applications, etc., can solve the problems of low efficiency of bean cutting process, easy to cut hands, etc., and achieve the effect of avoiding injury and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

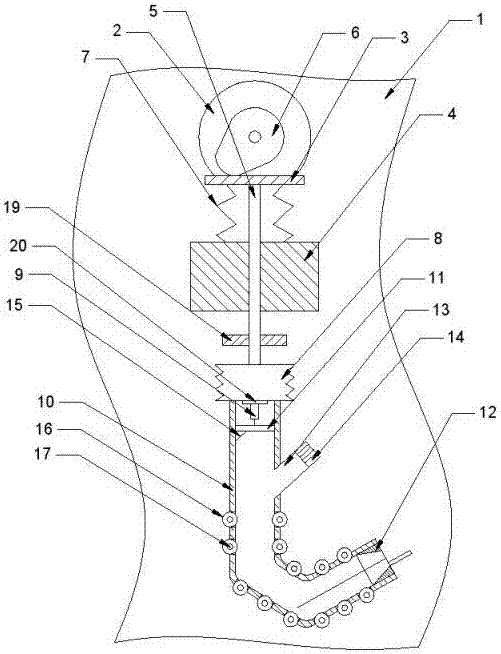

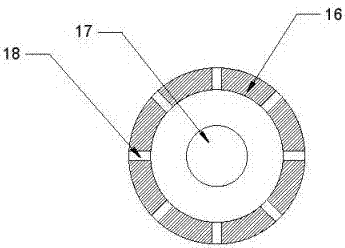

[0017] The reference signs in the drawings of the description include: frame 1, power motor 2, force plate 3, support platform 4, push rod 5, cam 6, first compression spring 7, inflatable bag 8, steel pipe 9, transportation pipe 10 , Movable plate 11, rubber sleeve 12, feed channel 13, sealing cover 14, second compression spring 15, circular shaft 16, heating resistor 17, cooling hole 18, guide plate 19, sealing ring 20.

[0018] The embodiment is basically as attached figure 1 , figure 2 Shown: The broad bean cutting device includes a frame 1. The frame 1 is provided with an intermittent mechanism, a transport mechanism and a knife from top to bottom in sequence. The intermittent mechanism includes a power motor 2, a force plate 3, a support table 4 and a push rod 5 , the power motor 2 and the support platform 4 are all fixedly connected to the frame 1, and the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com