Soft bean curd containing tea water and preparation process of soft bean curd

A technology of tofu and tea, which is applied in the food field, can solve the problems of nutritional value bonus discount, difficulty in guaranteeing, improvement of food nutritional structure level and less innovation, etc., to achieve the effect of improving the variety and content, and smoothing the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

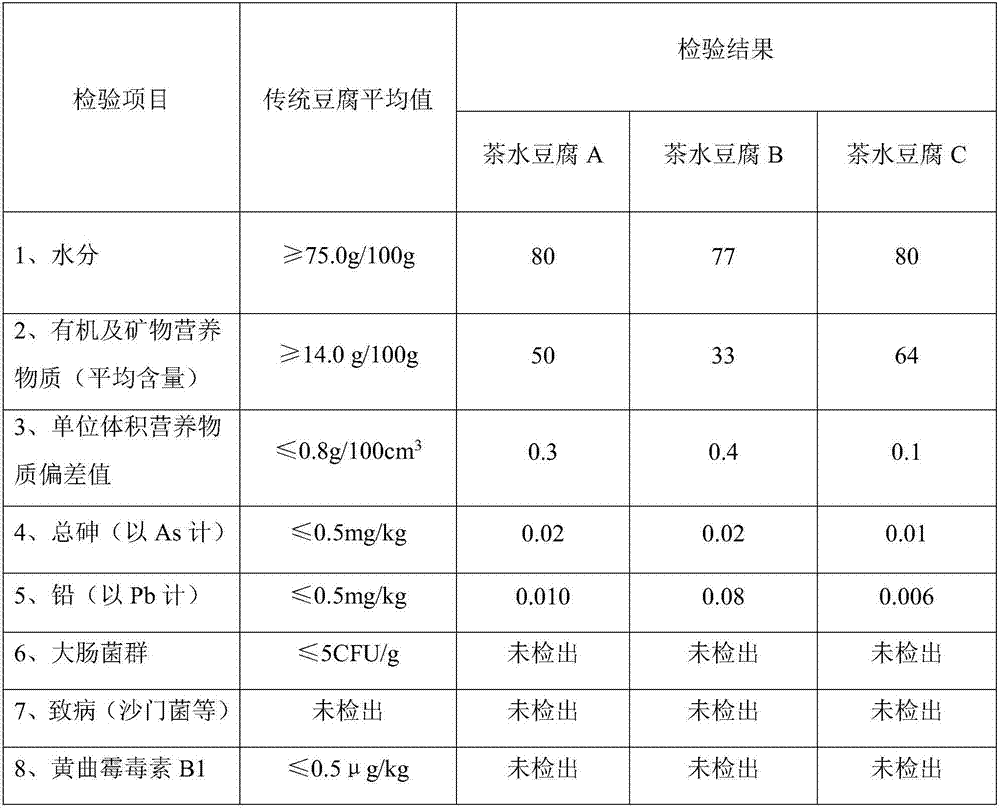

Examples

Embodiment 1

[0027] Embodiment 1: The preparation process of this tea tofu is based on the design purpose of mutual leading and uniform diffusion, and its specific preparation process includes the following steps, taking 550 parts of soybeans, 2250 parts of water, 11 parts of green tea, 2 parts of kudzu root powder, and 9 parts of sea salt , 2 parts of star anise, 3 parts of monosodium glutamate, 4 parts of stone alkali;

[0028] 1. Grinding the green tea into powder, extracting pueraria puerariae powder, pulverizing the star anise into powder, and then mixing the three according to the above weight ratio to make a main ingredient package; Cleanly pulverize, then filter with a 50-mesh sieve, add water to the filter residue and mash it for juice, let it stand for precipitation, dry it and filter it with a 100-mesh sieve, add water and mash it for juice, let it stand for precipitation, and dry it to get kudzu powder; green tea and star anise are crushed and crushed In the machine; in the mai...

Embodiment 2

[0038] Example 2: Take 450 parts of soybeans, 2750 parts of water, 7 parts of green tea, 5 parts of kudzu root powder, 7 parts of sea salt, 3 parts of star anise, 1 part of monosodium glutamate, and 8 parts of caustic soda;

[0039] 1. Grinding the green tea into powder, extracting pueraria pueraria powder, pulverizing the star anise into powder, and then mixing the three according to the above weight ratio to make a main ingredient package; Cleanly pulverize, then filter with a 50-mesh sieve, add water to the residue and mash it for juice, let it stand for precipitation, dry it and filter it with a 100-mesh sieve, add water and mash it for juice, let it stand for precipitation, and dry it to get kudzu powder; green tea and star anise are crushed and crushed in-flight;

[0040] 2. Mix the sea salt and monosodium glutamate according to the above weight ratio, and prepare an auxiliary material package;

[0041] 3. Put the soybeans into a container and soak for 3-6 hours; the so...

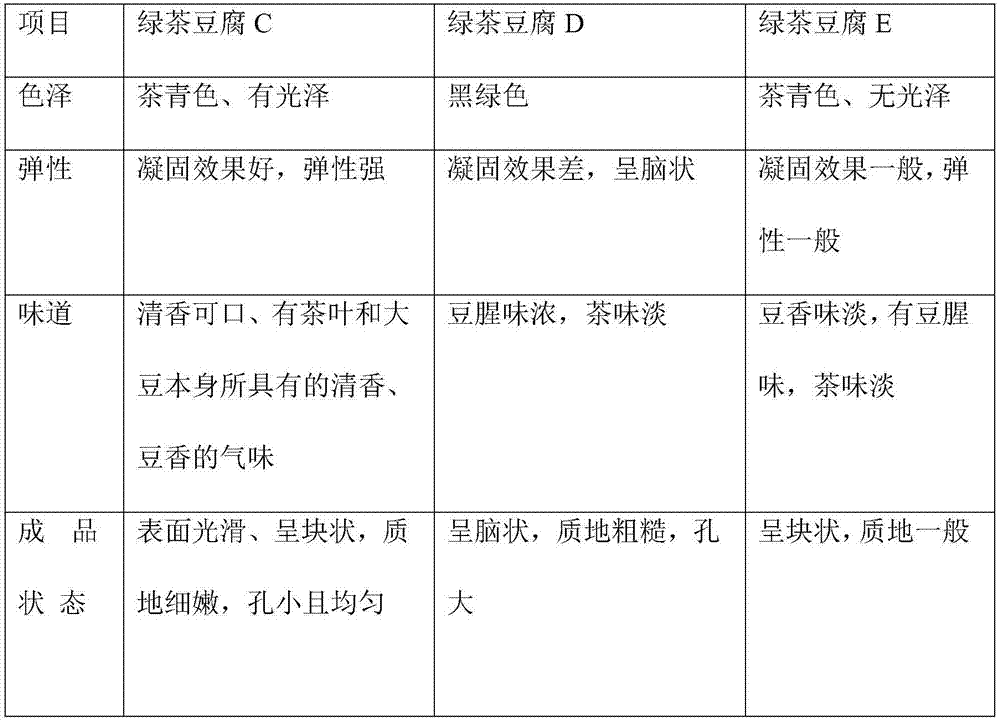

Embodiment 3

[0048] Example 3: Take 510 parts of soybeans, 2450 parts of water, 10 parts of green tea, 3 parts of kudzu root powder, 9 parts of sea salt, 1 part of star anise, 3 parts of monosodium glutamate, and 5 parts of caustic soda;

[0049] 1. Grinding the green tea into powder, extracting pueraria pueraria powder, pulverizing the star anise into powder, and then mixing the three according to the above weight ratio to make a main ingredient package; Cleanly pulverize, then filter with a 50-mesh sieve, add water to the residue and mash it for juice, let it stand for precipitation, dry it and filter it with a 100-mesh sieve, add water and mash it for juice, let it stand for precipitation, and dry it to get kudzu powder; green tea and star anise are crushed and crushed in-flight;

[0050] 2. Mix the sea salt and monosodium glutamate according to the above weight ratio, and prepare an auxiliary material package;

[0051] 3. Put the soybeans into a container and soak for 3-6 hours; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com