Composition for the permanent hydrophilic finishing of textile fibres and textile products

A composition and hydrophilic technology, applied in textiles and papermaking, fiber treatment, synthetic fibers, etc., can solve problems such as limited storage stability, and achieve the effect of maintaining the performance of the applied technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

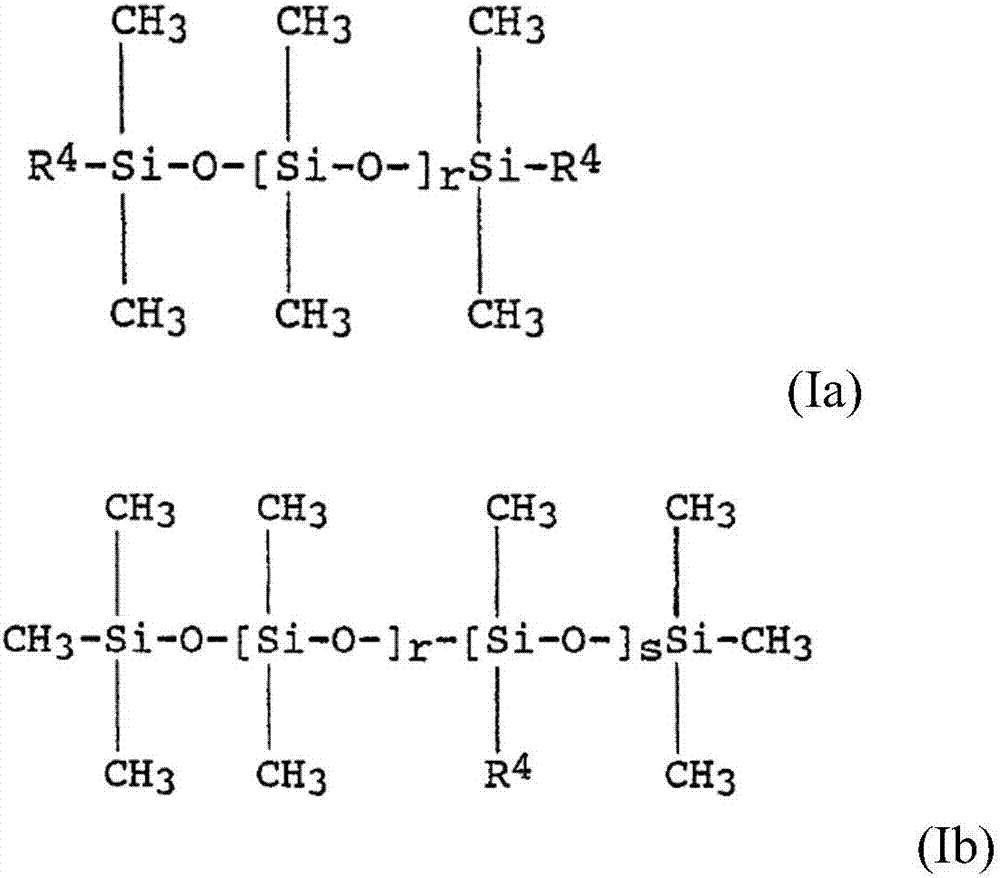

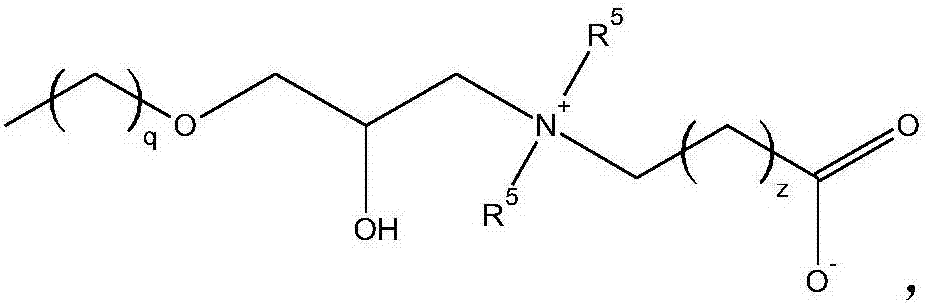

Method used

Image

Examples

Embodiment 1-3

[0108] The components given in Table 1 below were melted, mixed thoroughly with one another and pelletized from the melt. The average particle size of the granules is 5 mm. A 5% aqueous dispersion is then prepared from the granules thus obtained. The dispersion is applied to a weight per unit area of 15 g / m 2 SSS spunbonded nonwoven fabric made of polypropylene fibers. The coat weight was adjusted to 0.5%, based on the dry weight of the nonwoven.

[0109] Table 1

[0110]

[0111]

[0112]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com