Cage rotor and bar comprising a notch

A cage-type rotor and notch technology, which is applied in the field of manufacturing cage-type rotors and rods of cage-type rotors, can solve problems such as rising contact resistance and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

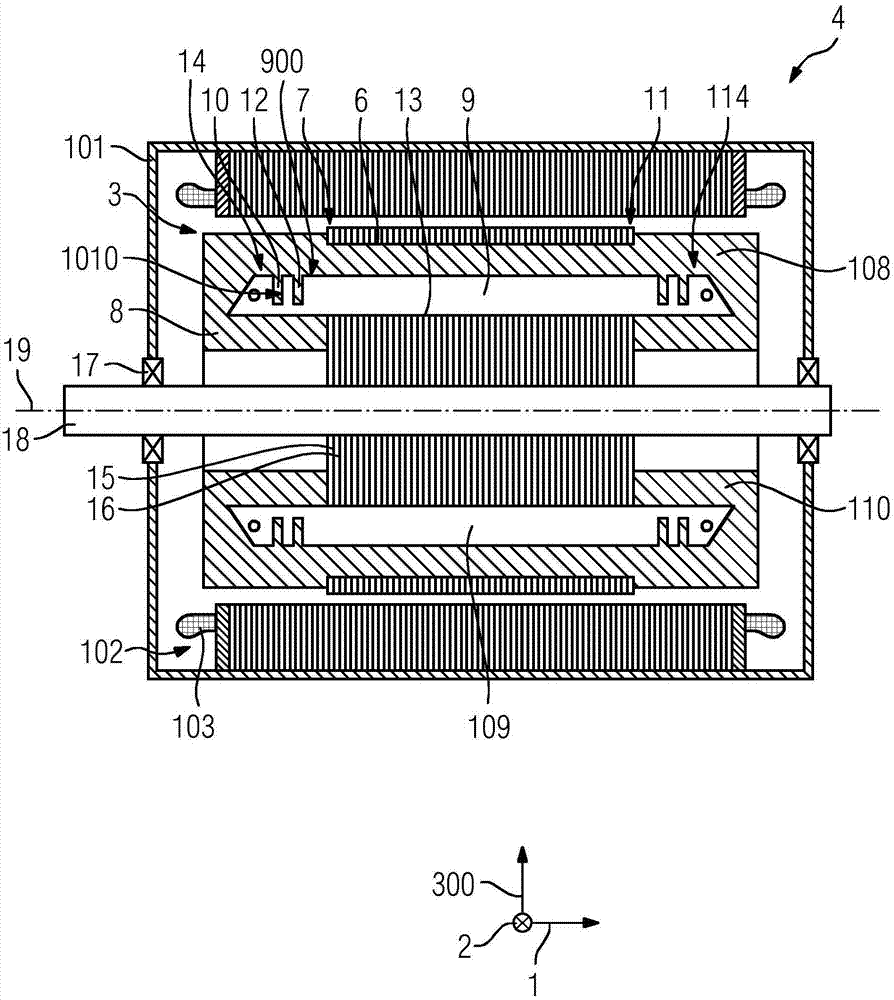

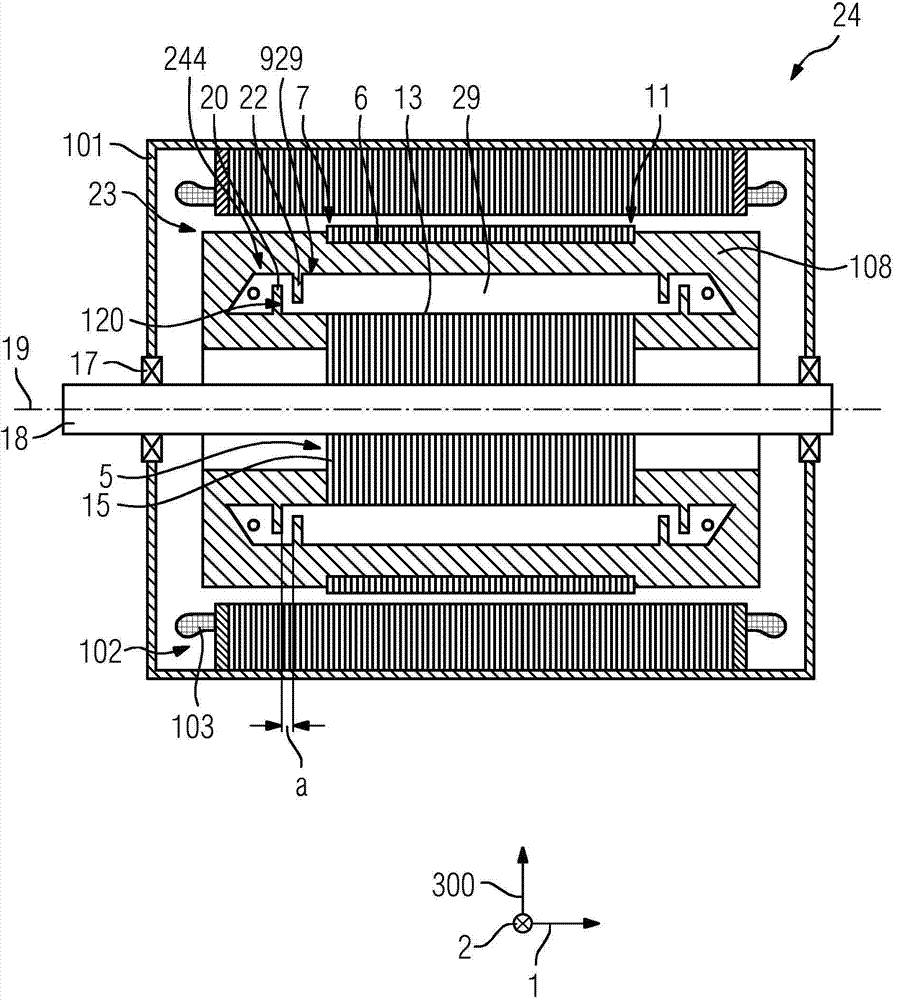

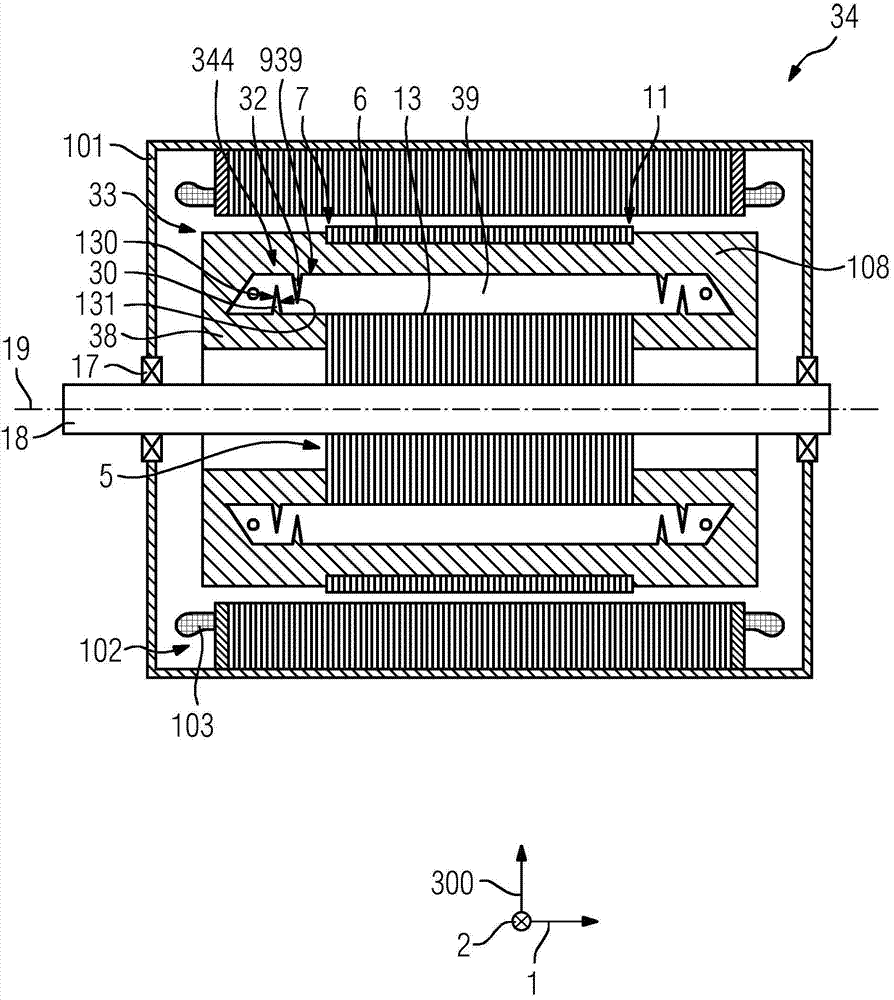

[0070] figure 1 A first embodiment of an electric machine 4 is shown, comprising a first embodiment of a cage rotor 3 . The electric machine 4 is an asynchronous machine and has a housing 101 in which a stator 102 is arranged. The stator 102 has a winding 103 . The cage rotor 3 is fastened on a shaft 18 , which is mounted rotatably about an axis of rotation in the housing 101 via rolling bearings 17 . The cage-type rotor 3 comprises a rotor stack 5 with slots 6, a short-circuit ring 8 cast at an axial end 7 of the rotor stack 5, and a rod 9 and a rod end 14 arranged in the slot 6, The short-circuit ring has a first material 108 . The rotor stack 5 comprises laminations, which are arranged in a stacked manner from an axial end 7 of the rotor stack 5 towards the other axial end 11 of the rotor stack 5 . The rotor stack 5 has, for example, a lamination 15 and a further lamination 16 at the axial end 7 . The rod end 14 can be bent through the recess 10 , wherein the recess 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com