Electrical connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, which is applied to the electrical connector with shielding effect and its manufacturing field, can solve problems such as short circuit of chip modules, and achieve the effect of satisfying high-frequency signal transmission and preventing short circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

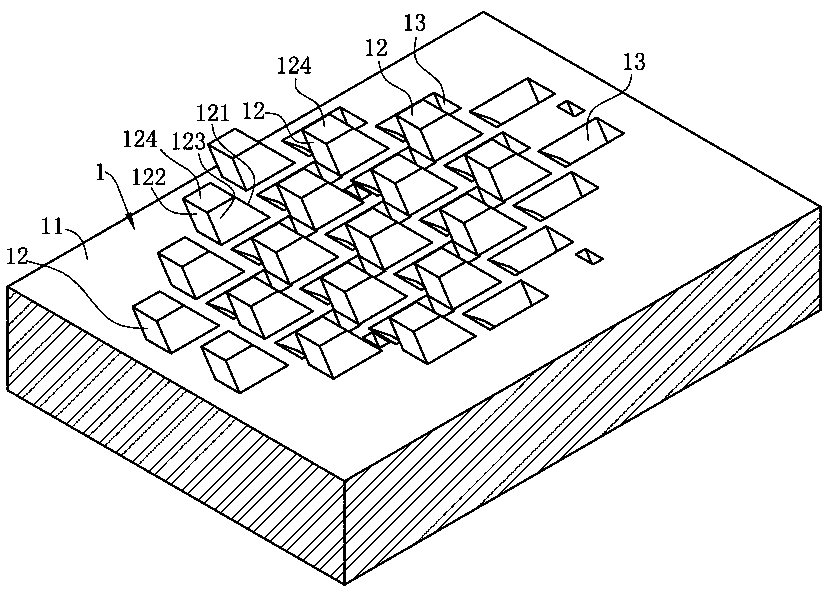

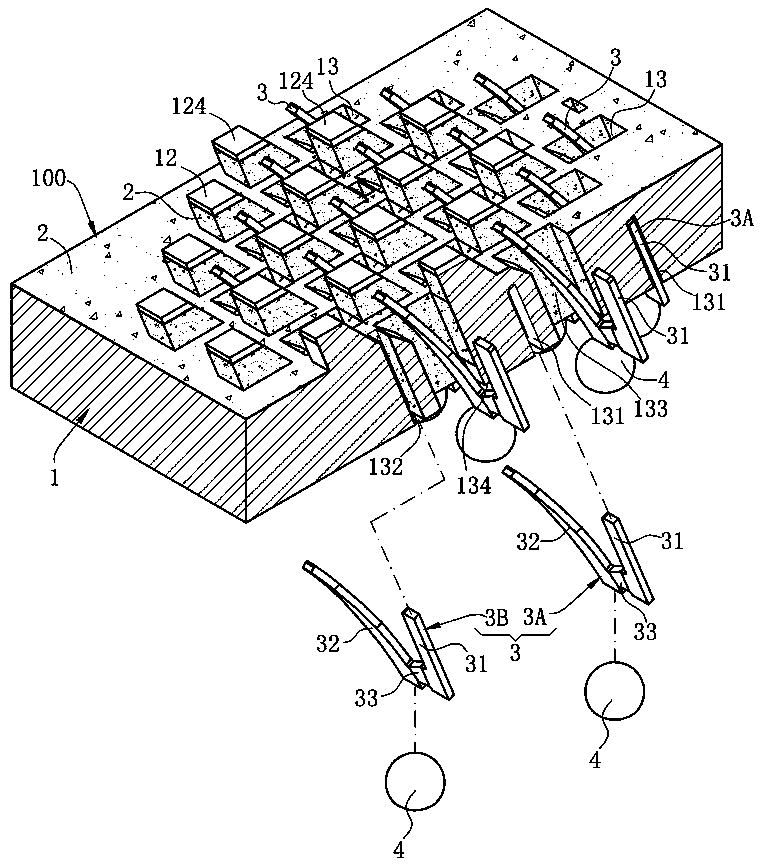

[0039] Such as figure 1 , image 3 and Figure 5 As shown, it is the first embodiment of the electrical connector 100 of the present invention. The electrical connector 100 of the present invention is an electrical connector 100 for electrically connecting a chip module 8 to a circuit board 9, which includes a body 1 The body 1 is provided with a plurality of receiving holes 13 arranged in multiple rows and columns, and a plurality of terminals 3 are respectively inserted into the receiving holes 13 from bottom to top, and one end of the terminals 3 elastically abuts against the chip module 8. The other end is soldered to the circuit board 9 through a solder ball 4, and a metal layer 2 is plated on the insulating body 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com