Composite lithium ion battery ternary cathode material and preparation method thereof

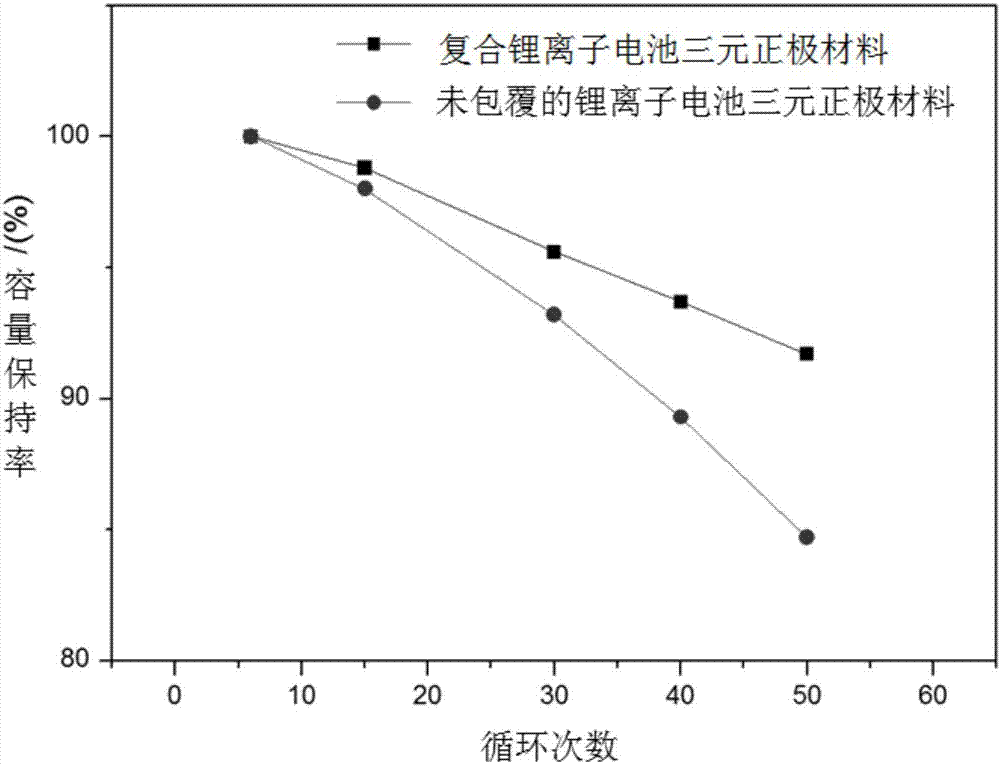

A technology for positive electrode materials and ion batteries, which is applied in the direction of battery electrodes, positive electrodes, electrical components, etc., can solve the problems of poor coating uniformity of ternary positive electrode materials, poor high-temperature cycle performance, and complex coating process, etc., and achieve excellent volumetric energy Density, improvement of processability, effect of avoiding volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] On the other hand, the embodiment of the present invention also provides a method for preparing the above-mentioned ternary positive electrode material for a composite lithium-ion battery. This preparation method comprises the steps:

[0028] S01: According to the general formula Li of nickel-cobalt-manganese ternary cathode material m Ni 1-x-y mn xco y o 2 In the molar ratio, nickel-cobalt-manganese intermediates and lithium sources are obtained, wherein, 0.98≤m≤1.10, 0.2≤x≤0.25, 0.2≤y≤0.25;

[0029] S02: performing the first mixing treatment on the nickel-cobalt-manganese intermediate and the lithium source to obtain the first mixture;

[0030] S03: heating the above-mentioned first mixture to 850-1000°C at a heating rate of 1-5°C / min, keeping it warm for 4-24h, and performing a second mixing treatment with an organoaluminum alcoholate after cooling to obtain a second mixture;

[0031] S04: After performing the third mixing treatment on the above-mentioned secon...

Embodiment 1

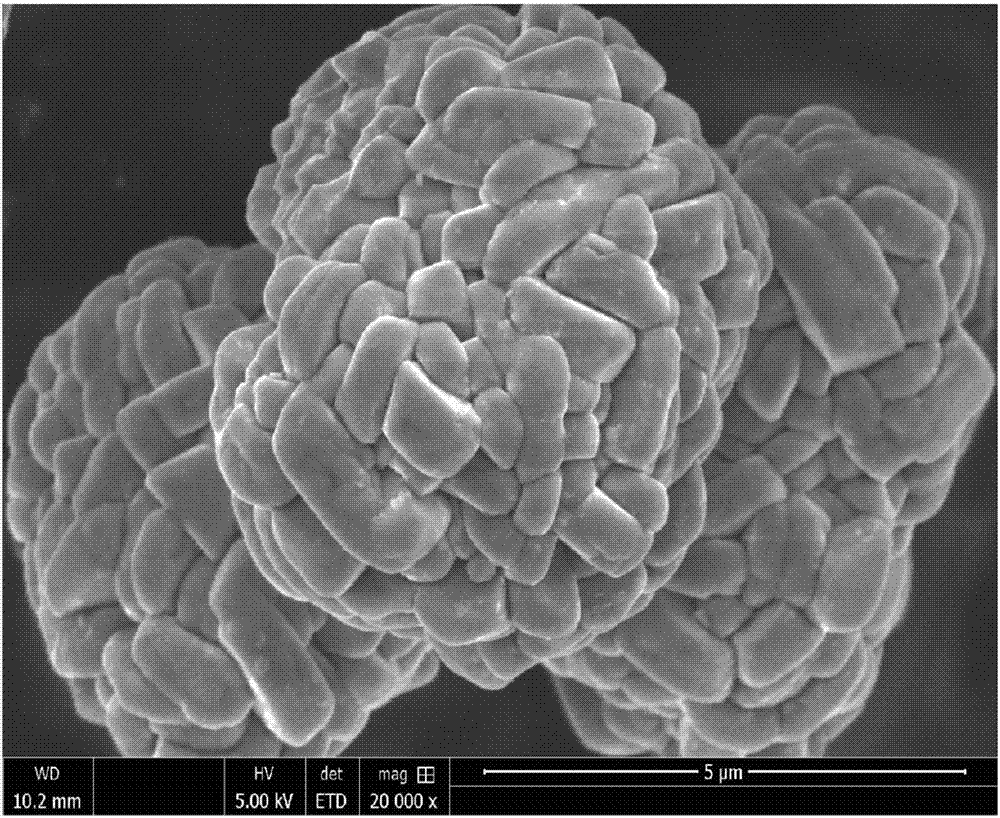

[0040] A composite lithium-ion battery ternary positive electrode material, comprising a nickel-cobalt-manganese ternary positive electrode material as an inner core and a cladding layer covering the nickel-cobalt-manganese ternary positive electrode material; the general formula of the nickel-cobalt-manganese ternary positive electrode material is Li 0.98 Ni 0.6 mn 0.2 co 0.2 o 2 , the cladding layer consists of Al 2 o 3 and LiAlO 2 composition. The preparation method of the composite lithium-ion battery ternary cathode material is as follows:

[0041] S11: Accurately weigh nickel-cobalt-manganese hydroxide (wherein the molar ratio of Ni:Mn:Co is 6:2:2) and lithium carbonate according to the molar ratio of Li / (Ni+Co+Mn)=0.98.

[0042] S12: Mix nickel-cobalt-manganese hydroxide and lithium carbonate in a ball mill for 0.1 hour.

[0043] S13: Put the mixed powder obtained in step S12 into a high-temperature furnace, heat up to 850°C at a heating rate of 1°C / min, keep wa...

Embodiment 2

[0048] A composite lithium-ion battery ternary positive electrode material, comprising a nickel-cobalt-manganese ternary positive electrode material as an inner core and a cladding layer covering the nickel-cobalt-manganese ternary positive electrode material; the general formula of the nickel-cobalt-manganese ternary positive electrode material is Li 1.10 Ni 0.55 mn 0.25 co 0.20 o 2 , the cladding layer consists of Al 2 o 3 and LiAlO 2 composition. The preparation method of the composite lithium-ion battery ternary cathode material is as follows:

[0049] S21: Accurately weigh nickel-cobalt-manganese carbonate (wherein the molar ratio of Ni:Mn:Co is 55:25:20) and lithium hydroxide according to the molar ratio of Li / (Ni+Co+Mn)=1.10.

[0050] S22: Mix nickel-cobalt-manganese carbonate and lithium hydroxide in a high-speed mixer for 4 hours.

[0051] S23: Put the mixed powder obtained in step S22 into a high-temperature furnace, heat up to 1000°C at a heating rate of 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com