Sheet-shaped heat sink capable of high-efficiency heat dissipation

A heat-dissipating, radiator technology, applied in transformer/inductor cooling, transformer/inductor parts, electrical components, etc., can solve the problem that the temperature of the transformer oil cannot be reduced to an ideal level, the air flow of the heat sink is poor, and the change is hindered. Oil pressure heat dissipation and other problems, to reduce the risk of oil leakage, improve the pressure resistance, and enhance the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The applicant will describe in detail in the form of the following examples, but the description of the examples is not a limitation to the technical solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only a formal rather than a substantive equivalent transformation All should be regarded as the scope of the technical solution of the present invention.

[0021] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and back are based on figure 1 The position shown is a reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention.

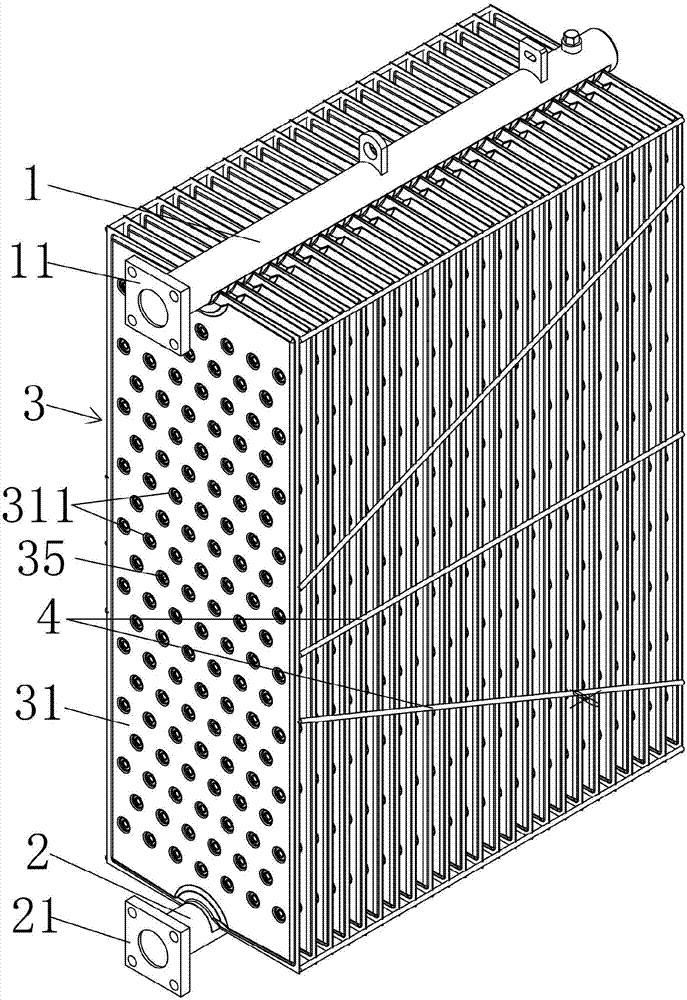

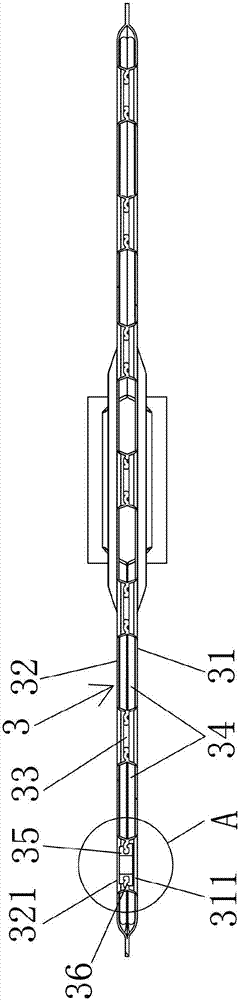

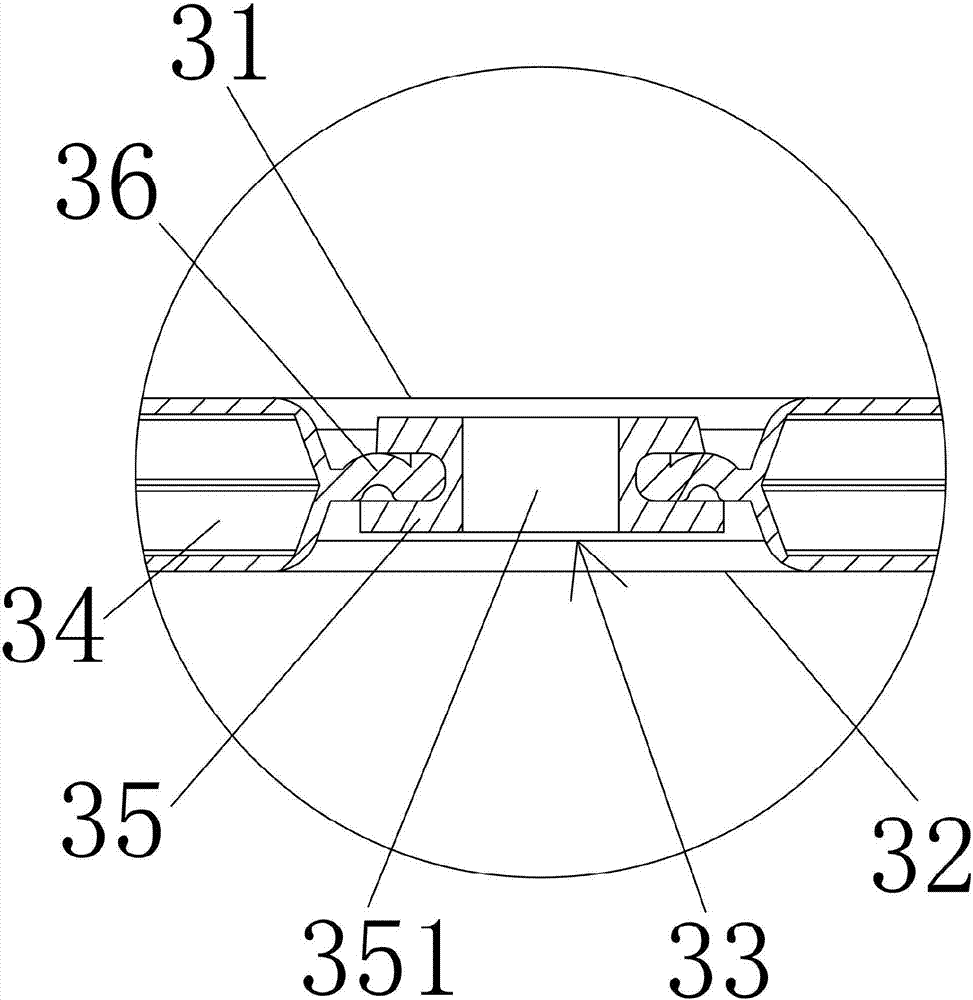

[0022] see figure 1 and combine figure 2 with image 3 , the present invention relates to a high-efficiency heat dissipation finned radiator, comprising an oil inlet pipe 1, an oil outlet pipe 2, and a group of oil inlet pipes arranged between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com