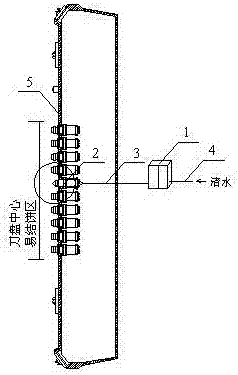

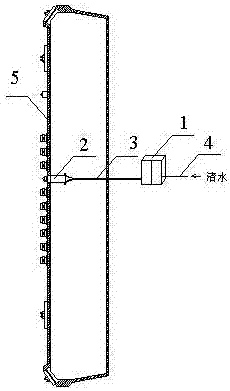

Shield structure cutter head mud cake cutting device and cutting method

A technology of shield cutter head and cutting device, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of central scouring device layout and pressure limitation, slow shield tunneling, limited scouring area, etc., and achieves good practicability , The effect of reducing operation risks and completely removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

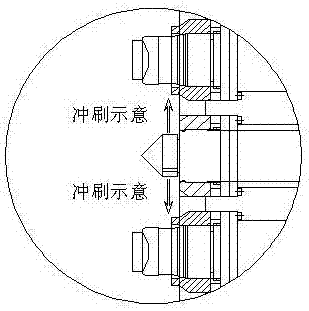

[0039] Embodiment 1: as Image 6 As shown, the nozzle group 2-2 is installed inside the spin-type nozzle 2-1, and the nozzle group 2-2 includes at least 3 nozzles, and the orthographic projection of the nozzles on the self-selecting nozzle 2-1 is The axis of the main shaft 2-3 is the center line and is symmetrically distributed in the spin nozzle 2-1.

[0040] As preferably, the nozzle group includes two cylindrical nozzles and a fan nozzle, a guide tube is installed in the cylindrical nozzle, and a one-way valve is installed at the outlet of the cylindrical nozzle and the fan nozzle to prevent jacking. Damaged and clogged when soiled.

[0041] There is an included angle between the installation direction of the guide tube 2-16 and the direction of the water outlet of the main shaft 2-3, which can drive the spin-type nozzle 2-1 to rotate under the impact of the water flow to perform mud cake cutting and cleaning work. There is an included angle between the installation direc...

Embodiment 2

[0042] Embodiment 2: The main shaft 2-3 is equipped with an impeller 2-7, and the impeller 2-7 is located in the water flow channel II. The role of the impeller in changing the water flow path is similar to that of a reflector. After high-pressure water is sprayed on the impeller, the water flow path can be changed.

Embodiment 3

[0043]Embodiment 3: The front end of the main shaft 2-3 is connected to the spin nozzle 2-1, the rear end of the main shaft 2-3 is installed on the main shaft mounting seat 2-4, and the front end of the main shaft mounting seat 2-4 A gland 2-5 is installed, and a cover 2-5 is installed behind the main shaft mounting seat 2-4, and the gland 2-5 is set on the main shaft 2-3, and the gland 2-5 is close to the main shaft A rotary pressure seal 2-6 is installed on one side of the 2-3.

[0044] The gland 2-5 is located in front of the spindle mounting seat 2-4, and is used to isolate the internal structure of the spindle mounting seat 2-4 from the external working space; the side of the gland 2-5 adjacent to the spindle 2-3 has a rotary pressure seal 2-6, which can prevent mud from entering the bearing under the working pressure of 6 bar. The cover 2-10 is located behind the main shaft mounting seat 2-4, and is used to close the water flow cavity at the front end of the cutter barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com