Antibacterial and insect-resistant packaging film for preharvest fruit and preparation method thereof

A packaging film and pre-harvest technology, applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve problems such as environmental pollution, harmful health, and damage to the growth and development of young fruits, and achieve a simple preparation process , easy to operate, and the effect of preventing pest erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

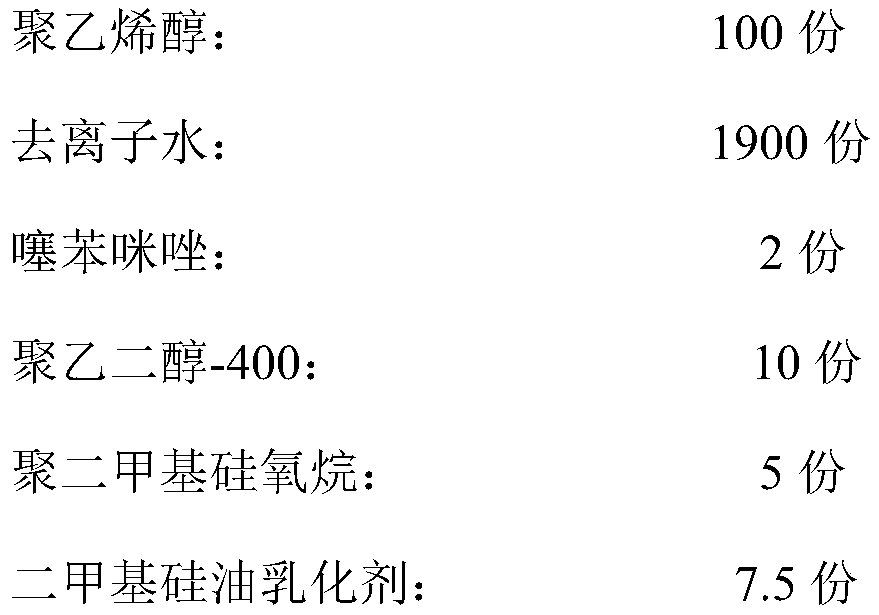

[0035]

[0036] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C; fully mix the simethicone emulsifier and polydimethylsiloxane, and use IKA mechanical stirring at a speed of 500-2000r / s to continue stirring for 20-40min until it is completely emulsified into a paste, emulsified The temperature is 25-100°C; pour thiabendazole, polyethylene glycol-400 and the emulsion into the prepared polyvinyl alcohol solution one by one, stir until fully mixed, and prepare the composite antibacterial film liquid.

[0037] Spray the polyvinyl alcohol composite antibacterial film liquid on the chickpea planted in the greenhouse in the form of spray through hydraulic equipment, and form a film on the chickpea; set the contr...

Embodiment 2

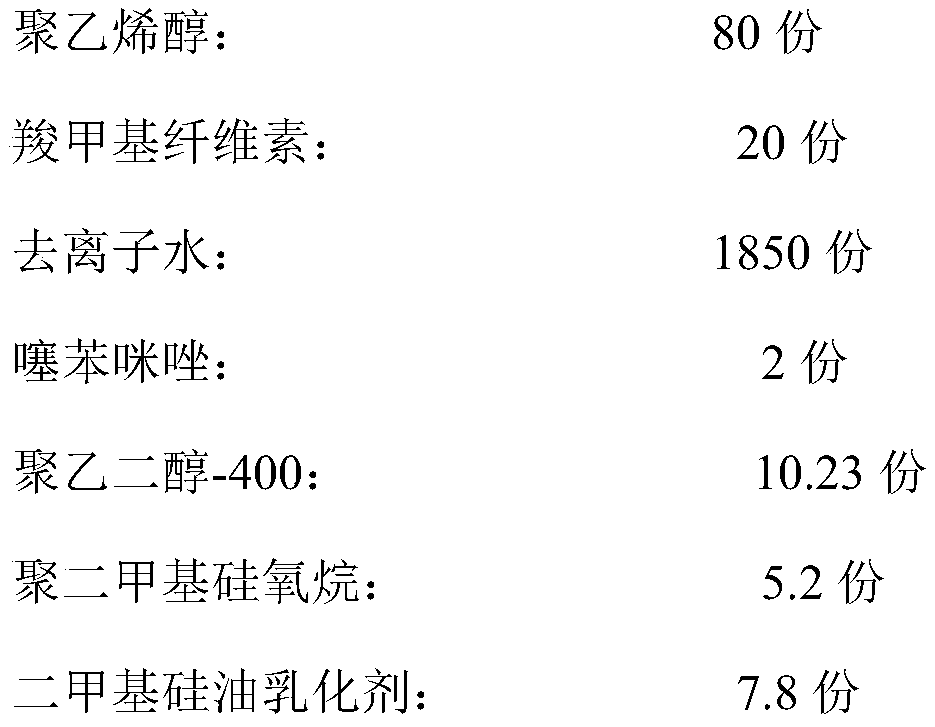

[0039]

[0040] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C, record it as solution A1; dissolve carboxymethyl cellulose in deionized water at 45°C, under constant temperature conditions, use DF-101S collector type constant temperature heating magnetic stirrer at a speed of 10-30r / s to continue Stir for 30 minutes, cool to room temperature, and record it as solution A2; blend the dissolved carboxymethyl cellulose solution A2 with the dissolved polyvinyl alcohol solution A1, and record it as solution A3; mix simethicone emulsifier with polyvinyl alcohol Mix the dimethylsiloxane thoroughly, and use IKA mechanical stirring at a speed of 500-2000r / s to continuously stir for 20-40min until it is completely ...

Embodiment 3

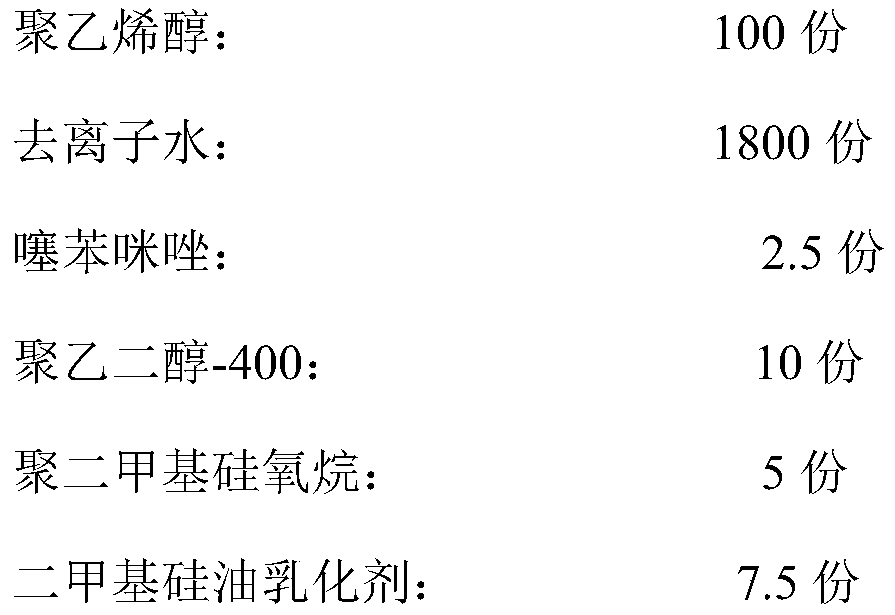

[0043]

[0044] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C; fully mix the simethicone emulsifier and polydimethylsiloxane, and use IKA mechanical stirring at a speed of 500-2000r / s to continue stirring for 20-40min until it is completely emulsified into a paste, emulsified The temperature is 25-100°C; pour thiabendazole, polyethylene glycol-400 and the emulsion into the prepared polyvinyl alcohol solution one by one, stir until fully mixed, and prepare the composite antibacterial film liquid.

[0045]Through the hydraulic equipment, the polyvinyl alcohol composite antibacterial film liquid was sprayed on the lotus mist planted in the greenhouse in the form of spray to form a film on the lotus mist; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com