Antibiosis pest-resistant packaging membrane used before fruit harvest

A packaging film and fruit technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve problems such as harmful health, damage to the growth and development of young fruits, and pollution of the environment. The effect of pest erosion, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

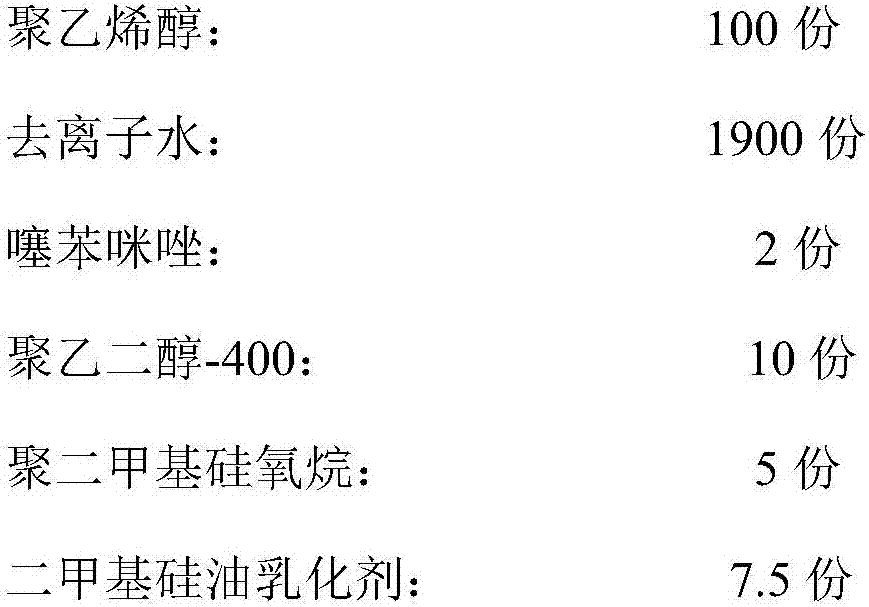

Embodiment 1

[0035]

[0036] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C; fully mix the simethicone emulsifier and polydimethylsiloxane, and use IKA mechanical stirring at a speed of 500-2000r / s to continue stirring for 20-40min until it is completely emulsified into a paste, emulsified The temperature is 25-100°C; pour thiabendazole, polyethylene glycol-400 and the emulsion into the prepared polyvinyl alcohol solution one by one, stir until fully mixed, and prepare the composite antibacterial film liquid.

[0037] Spray the polyvinyl alcohol composite antibacterial film liquid on the chickpea planted in the greenhouse in the form of spray through hydraulic equipment, and form a film on the chickpea; set the contr...

Embodiment 2

[0039]

[0040] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C, record it as solution A1; dissolve carboxymethyl cellulose in deionized water at 45°C, under constant temperature conditions, use DF-101S collector type constant temperature heating magnetic stirrer at a speed of 10-30r / s to continue Stir for 30 minutes, cool to room temperature, and record it as solution A2; blend the dissolved carboxymethyl cellulose solution A2 with the dissolved polyvinyl alcohol solution A1, and record it as solution A3; mix simethicone emulsifier with polyvinyl alcohol Mix the dimethylsiloxane thoroughly, and use IKA mechanical stirring at a speed of 500-2000r / s to continuously stir for 20-40min until it is completely ...

Embodiment 3

[0043]

[0044] The above groups are measured separately. First, dissolve polyvinyl alcohol in deionized water at 98°C. Under constant temperature conditions, use a DF-101S collector type constant temperature heating magnetic stirrer to continue stirring at a speed of 10-30r / s for 30 minutes to completely dissolve. After cooling to 45°C; fully mix the simethicone emulsifier and polydimethylsiloxane, and use IKA mechanical stirring at a speed of 500-2000r / s to continue stirring for 20-40min until it is completely emulsified into a paste, emulsified The temperature is 25-100°C; pour thiabendazole, polyethylene glycol-400 and the emulsion into the prepared polyvinyl alcohol solution one by one, stir until fully mixed, and prepare the composite antibacterial film liquid.

[0045]Through the hydraulic equipment, the polyvinyl alcohol composite antibacterial film liquid was sprayed on the lotus mist planted in the greenhouse in the form of spray to form a film on the lotus mist; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com