Ultra-light aerogel heat insulation material with waterproof and moisture permeation functions and preparation method thereof

A technology of waterproof and moisture-permeable and waterproof and moisture-permeable membranes, which is applied in the field of clothing thermal insulation materials, can solve the problems of poor mechanical strength, hindering thermal insulation performance, and restrictions, and achieve the effects of reducing thermal conductivity, improving thermal insulation performance, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

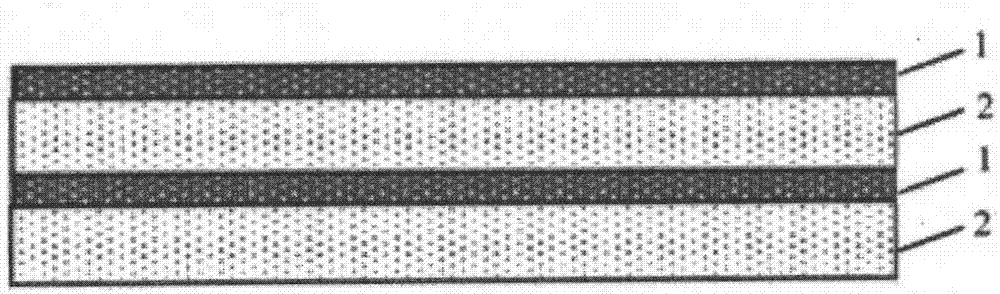

[0058] like figure 1 As shown, an ultra-light airgel thermal insulation material with waterproof and moisture-permeable function includes down-like structural fiber airgel 2 and a waterproof and moisture-permeable membrane 1 compounded on the down-like structural fiber airgel 2 .

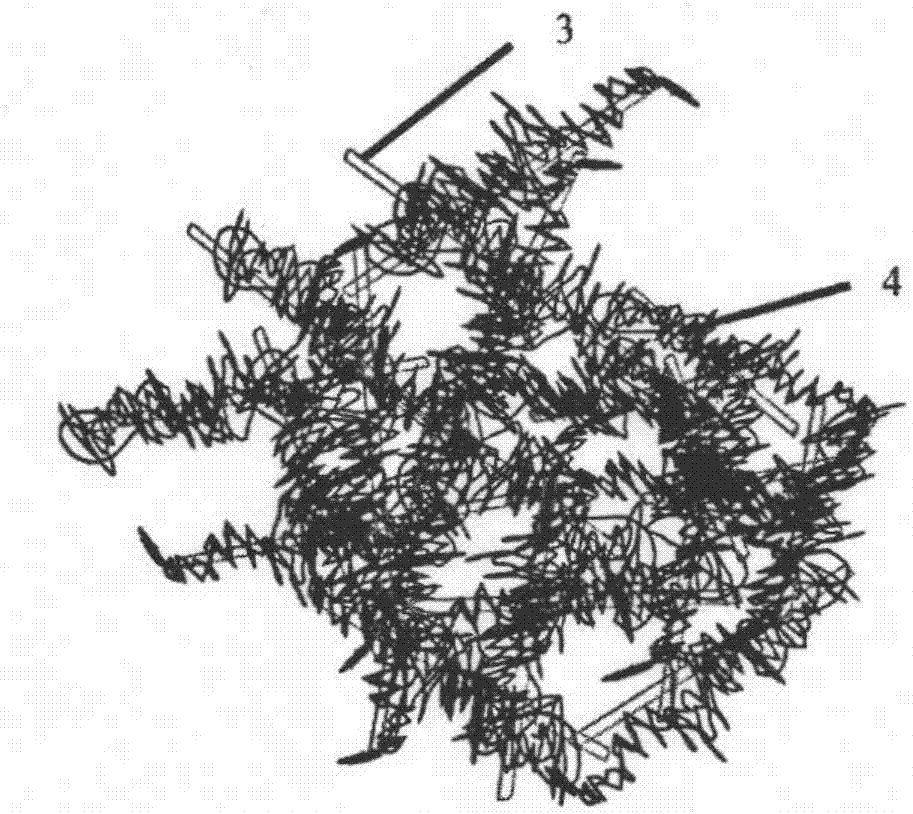

[0059] like figure 2 As shown, the down-like structural fiber airgel 2 includes thick fibers 3 and thin fibers 4 .

[0060] The preparation method of the ultra-light airgel thermal insulation material with waterproof and moisture-permeable function is:

[0061] The first step: using electrospinning technology, inject 25g of cellulose acetate spinning solution with a mass fraction of 8% into a fine-needle syringe with a needle diameter of 0.38mm, and inject 25g of polyvinyl butyral with a mass fraction of 20% The spinning solution is injected into a thick needle syringe with a needle diameter of 1.2mm, and the two syringes are placed alternately, with non-woven fabric as the receiving substrate an...

Embodiment 2

[0068] like figure 1 As shown, an ultra-light airgel thermal insulation material with waterproof and moisture-permeable function includes down-like structural fiber airgel 2 and a waterproof and moisture-permeable membrane 1 compounded on the down-like structural fiber airgel 2 .

[0069] like figure 2 As shown, the down-like structural fiber airgel 2 includes thick fibers 3 and thin fibers 4 .

[0070] The preparation method of the ultra-light airgel thermal insulation material with waterproof and moisture-permeable function is:

[0071] The first step: using electrospinning technology, inject 25g of polyvinyl alcohol spinning solution with a mass fraction of 10% into a fine-needle syringe with a needle diameter of 0.28mm, and spin 20g of polycaprolactone with a mass fraction of 16% The liquid is injected into a thick needle syringe with a needle diameter of 1.1mm, and the two syringes are placed alternately, with non-woven fabric as the receiving substrate and the electro...

Embodiment 3

[0078] like figure 1 As shown, an ultra-light airgel thermal insulation material with waterproof and moisture-permeable function includes down-like structural fiber airgel 2 and a waterproof and moisture-permeable membrane 1 compounded on the down-like structural fiber airgel 2 .

[0079] like figure 2 As shown, the down-like structural fiber airgel 2 includes thick fibers 3 and thin fibers 4 .

[0080] The preparation method of the ultra-light airgel thermal insulation material with waterproof and moisture-permeable function is:

[0081] The first step: using electrospinning technology, inject 20g of polyvinylpyrrolidone spinning solution with a mass fraction of 12% into a fine-needle syringe with a needle diameter of 0.18mm, and inject 20g of polymethyl methacrylate with a mass fraction of 10% The spinning solution is injected into a thick needle syringe with a needle diameter of 1.0mm, and the two syringes are placed alternately, with non-woven fabric as the receiving su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com