Hand-wiping paper and preparation method thereof

A technology of paper towels and paper surfaces, which is applied in the field of papermaking, can solve problems such as poor softness and wiping comfort, high consumption of tree resources, and rough hand towels, etc., to achieve good water absorption, wide use, and excellent stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Feed 1000kg of natural-color bamboo fiber, pulp it through a hydraulic pulper for 5 minutes, and the pulping concentration is 10%; then add water to dilute it to 5%, refine it with a double disc mill and a cone mill until the degree of knocking is 30°SR, and then add polyamide - Epichlorohydrin resin wet strength agent 80kg, use after diluting the wet strength agent to 12.5% with water. Paper towel sheet 1 of single-layer quantitative 21 grams is formed through paper machine.

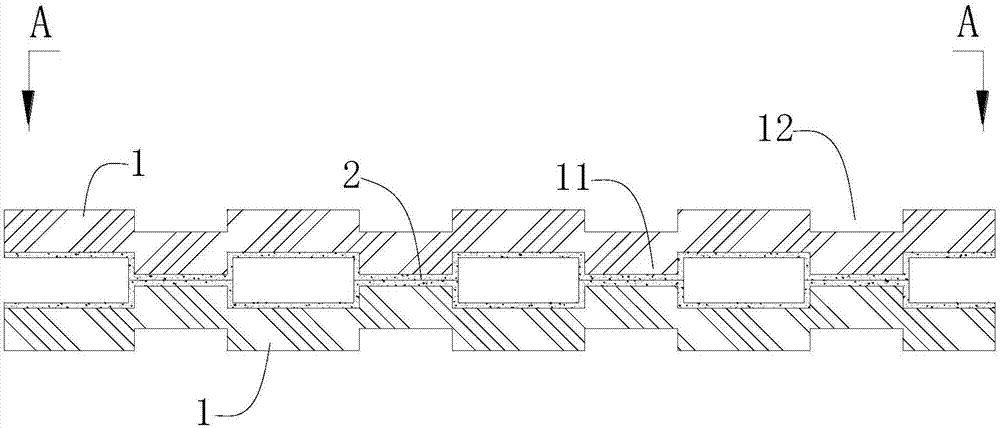

[0033] The single page 1 of the paper towel is embossed by a special dot-shaped embossing roller to form a cylindrical single-page convex part 11 and a single-page concave part 12, such as image 3 As shown, the diameter of the surface circle of the convex portion 11 of a single page is 0.5 mm, the height of the convex portion 11 of a single page is 0.5 mm, and the distance between a plurality of convex portions 11 of a single page is 0.5 mm. For the embossed paper towel sheet 1, starch glue d...

Embodiment 2

[0035] Feed 1000kg of natural-color bamboo fiber, pulp it through a hydraulic pulper for 5 minutes, and the pulping concentration is 10%; then add water to dilute it to 5%, refine it with a double disc mill and a cone mill until the degree of beating is 30°SR, and then add formaldehyde resin Wet strength agent 80kg, the wet strength agent is diluted to 12.5% with water before use. Paper towel sheet 1 of single-layer quantitative 21 grams is made through paper machine.

[0036] The single page 1 of the paper towel is embossed by a special square dot-shaped embossing roller to form a square columnar single-page convex part 11 and a single-page concave part 12, such as Figure 4 As shown, the side length of the square on the top surface of the single-page convex portion 11 is 0.5mm, the height of the single-page convex portion 11 is 0.5mm, and the distance between multiple single-page convex portions 11 is 0.5mm. For the embossed paper towel sheet 1, use starch glue and water ...

Embodiment 3

[0038] Feed 1000kg of natural-color bamboo fiber, pulp it through a hydraulic pulper for 5 minutes, and the pulping concentration is 10%; then add water to dilute it to 5%, refine it with a double disc mill and a cone mill until the knocking degree is 30°SR, then add polyamide - Epichlorohydrin resin wet strength agent 80kg, use after diluting the wet strength agent to 12.5% with water. Paper towel sheet 1 of single-layer quantitative 21 grams is formed through paper machine.

[0039] The sheet 1 of the paper towel is embossed by a special dot-shaped embossing roller to form a cylindrical single-page convex part 11 and a single-page concave part 12. The diameter of the surface circle of the single-page convex part 11 is 0.5 mm, and the height of the single-page convex part 11 is is 0.5 mm, and the distance between the plurality of single-sheet convex portions 11 is 0.5 mm. For the embossed paper towel sheet 1, starch glue diluted with water in a mass ratio of 1:3 is glued o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com