Mesh electrode tandem type electrohydrodynamic micro-pump and method

A mesh electrode, tandem technology, applied in electrical components, electromechanical devices, etc., can solve the problems of low pump pressure and poor driving effect, and achieve the effect of increasing the area range, reducing resistance, and enhancing tip discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

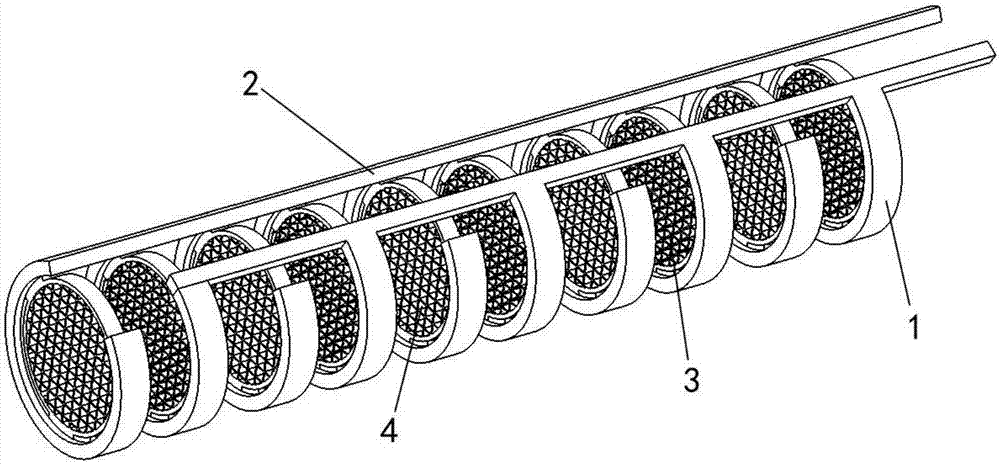

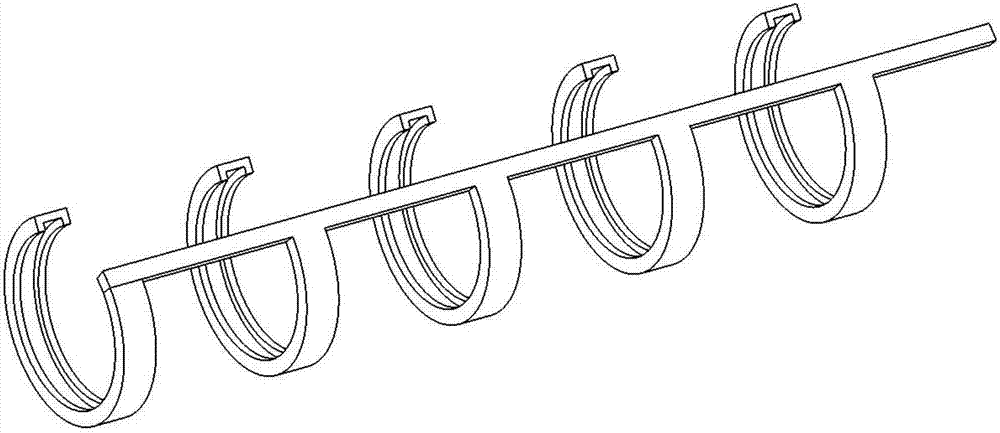

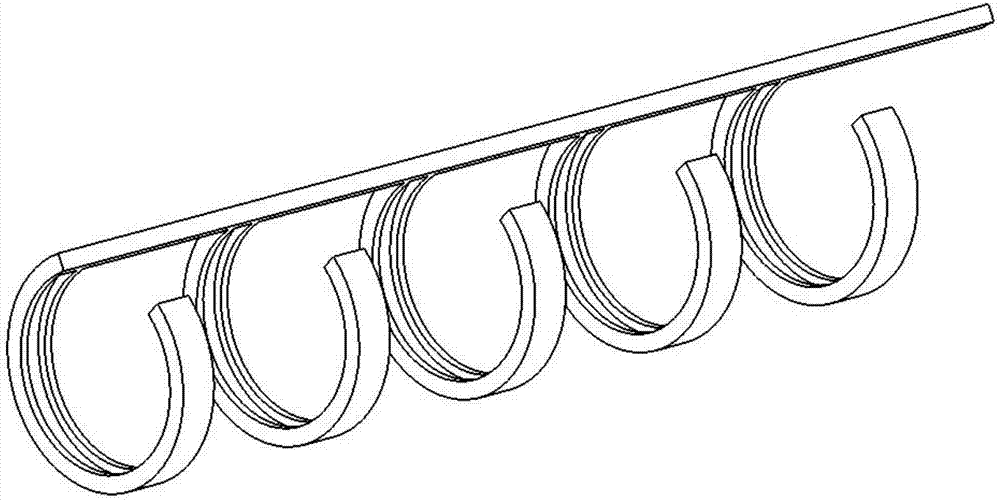

[0033] Such as Figure 1 to 6 Shown. The invention discloses a series-type electrohydrodynamic micropump with mesh electrodes, which comprises a left electrode supporting guide rod 1 and a right electrode supporting guide rod 2;

[0034] Along the axial direction of the left electrode support guide rod 1, a plurality of mesh emitters 3 are arranged in an array and at intervals;

[0035] Along the axial direction of the right electrode support guide rod 2, a plurality of mesh collector electrodes 4 are distributed in an array and at intervals;

[0036] The mesh emitter 3 and the mesh collector 4 are arranged alternately with each other to form a comb-like electrode array with positive and negative electrodes axially alternately arranged;

[0037] The comb electrode array is placed in the micropump cavity; the left electrode support guide rod 1 and the right electrode support guide rod 2 extend out of the free ends of the comb electrode array, and are connected to the positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com