Construction method of preassembly supporting beam combined system

A construction method and technology for supporting beams, which are applied in excavation, infrastructure engineering, construction, etc., can solve the problems of difficult demolition of supports, high construction costs, damage to the environment, etc., and achieve the effects of quick installation and demolition, convenient demolition, and guaranteed construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described

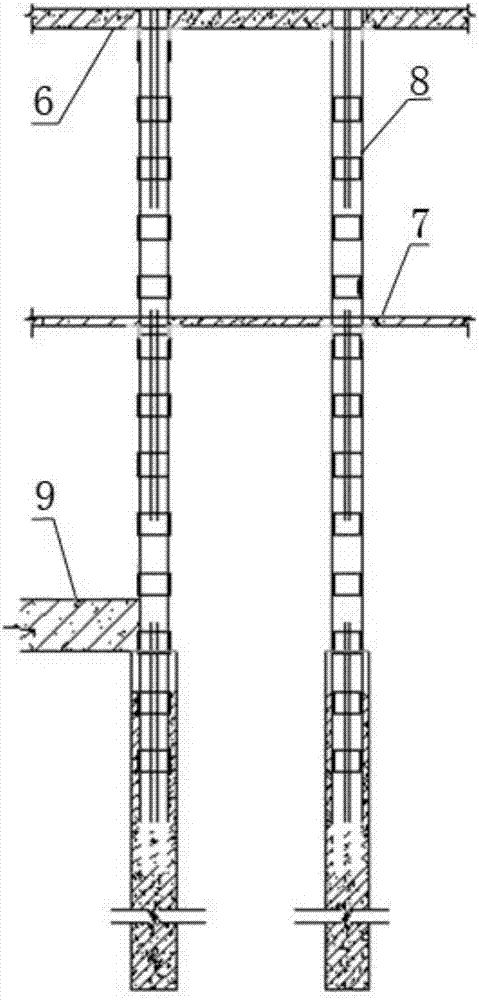

[0022] as attached figure 1 , 2 As shown, the construction method of the pre-assembled support beam composite system includes the following steps:

[0023] Step 1, the prefabrication of the concrete support beam is to determine the prefabrication of the concrete support beam into sections according to the construction plan, and prefabricate a single concrete support beam into 4 sections. At both ends of each concrete support beam, steel bars are reserved for steel bar joints, and steel plates are pre-embedded on the sides.

[0024] The prefabrication process of the concrete support beams is carried out in the processing plant, and the formwork is used for turnover. Precast concrete support beams must be pre-assembled before leaving the factory, and all technical indicators must meet the requirements before leaving the factory.

[0025] Step 2. Concrete support beam erec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com