Self-adjusting loosening device

A self-adjusting and equipment technology, which is applied in the direction of fiber opening and cleaning machines, opening and cleaning with toothed tools, etc., can solve the problem of fiber winding in the opening drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

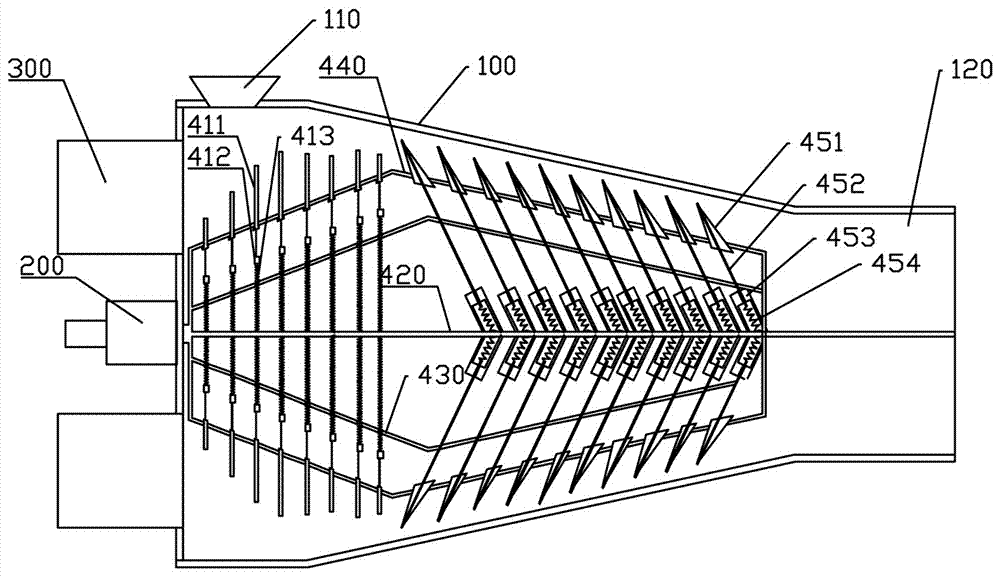

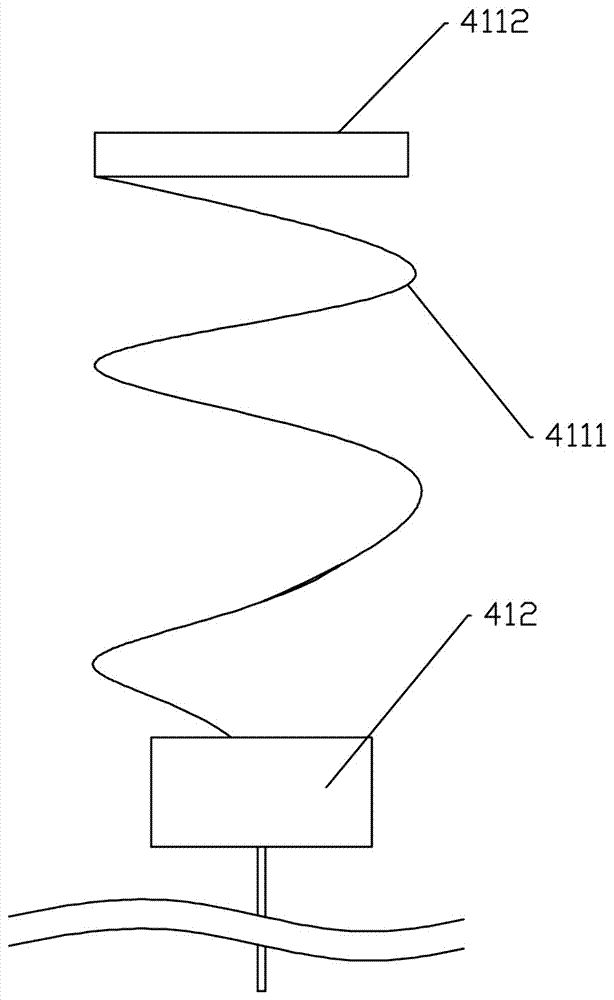

[0020] The reference signs in the drawings of the description include: opening bin 100, feeding hopper 110, discharge port 120, rotating power part 200, air intake pipe 300, rotary cutting teeth 411, cutting wire 4111, limit plate 4112, counterweight Block 412, quick-cut extension spring 413, rotating shaft 420, inner retaining cylinder 430, cylinder wall 440, opening mechanism 450, opening thorn 451, slide bar 452, sliding barrel 453, opening extension spring 454.

[0021] Such as figure 1 The self-adjusting opening device shown includes an opening bin 100, a rotating power part 200, an air intake pipe 300 and an opening drum. The opening bin 100 is in the shape of a cone, and the opening bin 100 includes a The feed hopper 110 and the discharge port 120 opened on the right side wall of the opening bin 100, the air inlet pipe 300 communicates with the left side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com