A space-borne composite heat dissipation system and its control method

A heat dissipation system and space-borne technology, applied in the field of aerospace environmental control, can solve problems such as hidden dangers of unit reliability, achieve the effects of reducing area, meeting heat dissipation requirements, and ensuring heat dissipation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

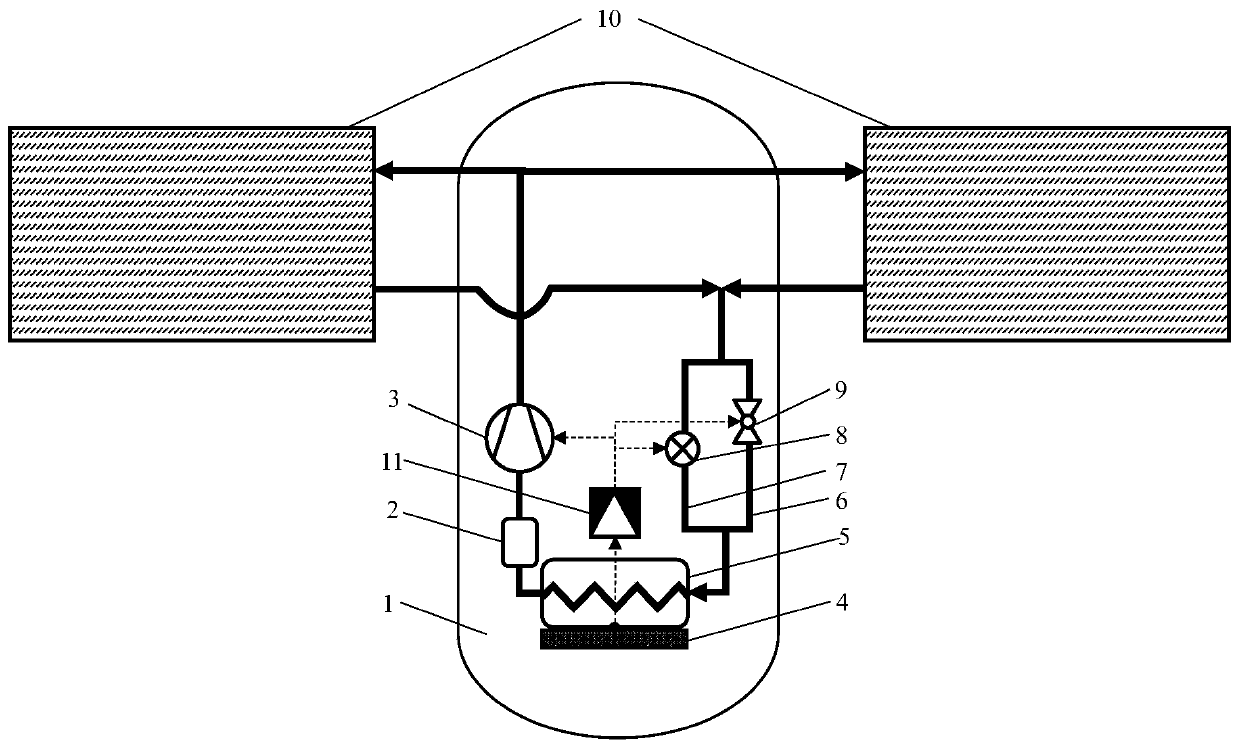

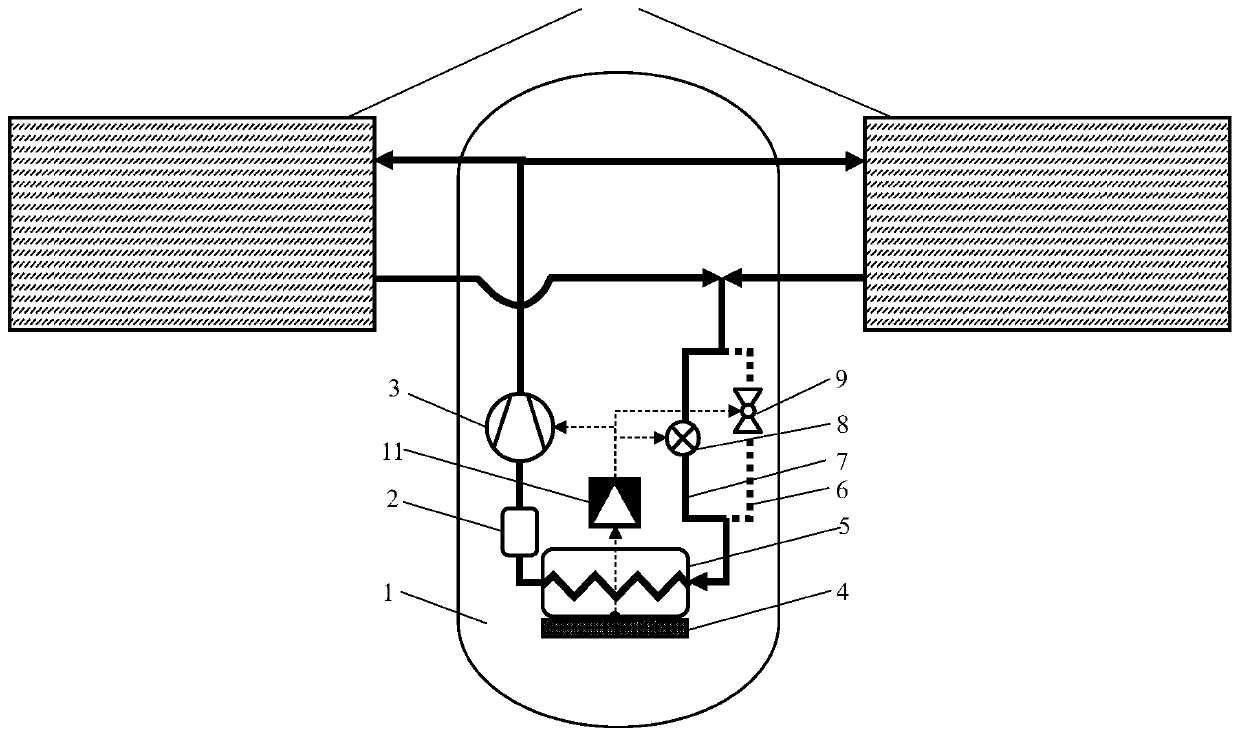

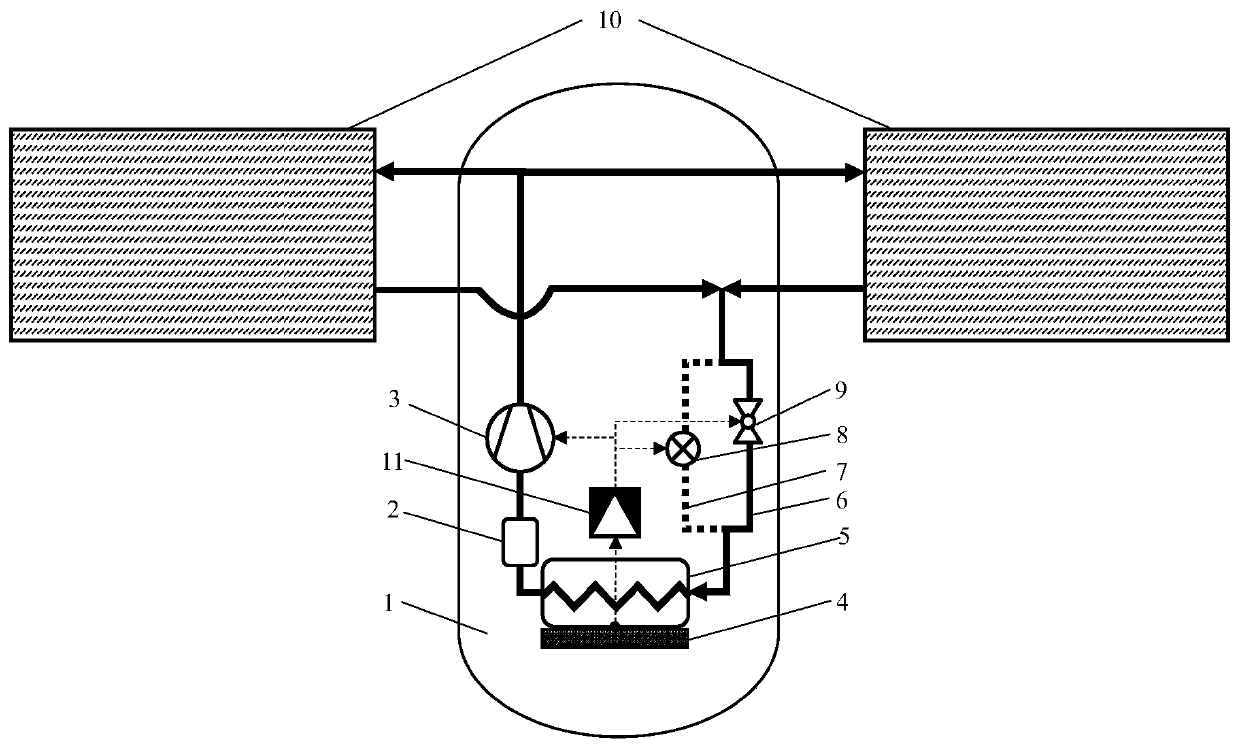

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The space-borne composite heat dissipation system of the present invention includes a satellite cabin 1, a gas-liquid separator 2, a compressor 3, a heating device 4, an evaporator 5, a bypass branch 6, a throttling branch 7, a radiation radiator 10, and a controller 11 And the refrigerant pipeline, the evaporator 5 is sequentially connected with the gas-liquid separator 2, the compressor 3, the radiation radiator 10 and the throttling branch 7 through the refrigerant pipeline, and the throttling branch 7 and the bypass branch 6 are connected in parallel Setting, a throttling device 8 is set on the throttling branch 7, and a bypass valve 9 is set on the bypass branch. The compressor 3 is a miniature oil-free variable-frequency compressor with adjustable pressure ratio and rotating speed. The controller 11 collects the surface temperature of the heating device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com