Ethylene-acrylic elastomer turbocharging rubber hose and manufacturing method thereof

An ethylene acrylate and turbocharging technology, which is applied to rubber layered products, chemical instruments and methods, hoses, etc., can solve the problems of high turbocharger speed, difficult production, high technical content, etc., and meet the requirements of use , the effect of high burst pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

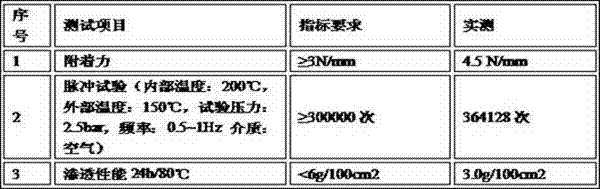

Embodiment 1

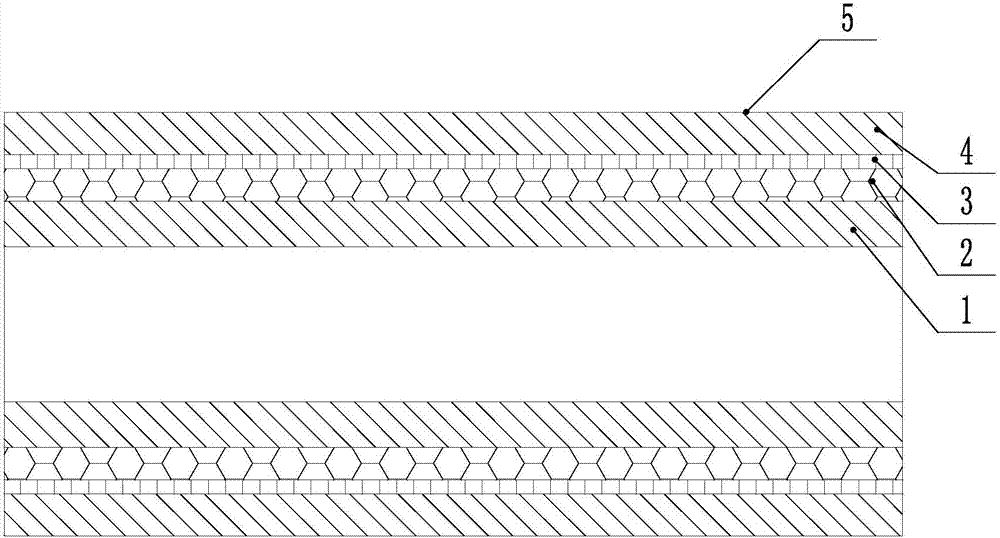

[0014] An ethylene acrylate rubber turbocharger rubber hose, including a rubber hose, is characterized in that: the rubber hose is composed of a fluorine rubber inner layer, an ethylene acrylate rubber middle layer, an aramid fiber layer and an ethylene acrylate rubber outer layer, and the The thickness of the fluorine rubber inner layer is 0.4 mm, the thickness of the ethylene acrylate rubber middle layer is 1 mm, the thickness of the aramid thread layer is 0.1 mm, and the thickness of the ethylene acrylate rubber outer layer is 1 mm.

[0015] The manufacturing method of above-mentioned a kind of ethylene acrylate rubber turbocharger rubber hose, comprises the following steps:

[0016] 1) Tube embryo manufacturing process

[0017] Extrude inner rubber and middle rubber: Extrude fluorine rubber and ethylene acrylate rubber on the dual compound extruder at the same time, set the extrusion temperature of inner rubber fluorine rubber to 70°C, 60°C, 50°C, 40°C, 50°C, The extrusio...

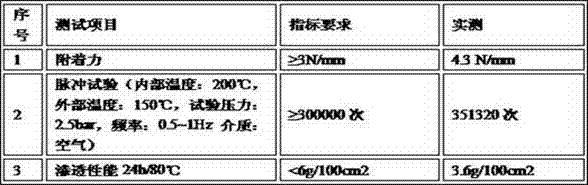

Embodiment 2

[0024] An ethylene acrylate rubber turbocharger rubber hose, including a rubber hose, is characterized in that: the rubber hose is composed of a fluorine rubber inner layer, an ethylene acrylate rubber middle layer, an aramid fiber layer and an ethylene acrylate rubber outer layer, and the The thickness of the fluorine rubber inner layer is 1.0 mm, the thickness of the ethylene acrylate rubber middle layer is 4 mm, the thickness of the aramid fiber layer is 2 mm, and the thickness of the ethylene acrylate rubber outer layer is 4 mm.

[0025] The manufacturing method of above-mentioned a kind of ethylene acrylate rubber turbocharger rubber hose, comprises the following steps:

[0026] 1) Tube embryo manufacturing process

[0027] Extrude inner rubber and middle rubber: Extrude fluorine rubber and ethylene acrylate rubber on the dual compound extruder at the same time, set the extrusion temperature of inner rubber fluorine rubber to 80°C, 70°C, 60°C, 50°C, 60°C, The extrusion t...

Embodiment 3

[0034] An ethylene acrylate rubber turbocharger rubber hose, including a rubber hose, is characterized in that: the rubber hose is composed of a fluorine rubber inner layer, an ethylene acrylate rubber middle layer, an aramid fiber layer and an ethylene acrylate rubber outer layer, and the The thickness of the fluorine rubber inner layer is 0.7 mm, the thickness of the ethylene acrylate rubber middle layer is 2.5 mm, the thickness of the aramid fiber layer is 1 mm, and the thickness of the ethylene acrylate rubber outer layer is 2.5 mm.

[0035] The manufacturing method of above-mentioned a kind of ethylene acrylate rubber turbocharger rubber hose, comprises the following steps:

[0036] 1) Tube embryo manufacturing process

[0037] Extrude inner rubber and middle rubber: Extrude fluorine rubber and ethylene acrylate rubber on the dual compound extruder at the same time, set the extrusion temperature of inner rubber fluorine rubber to 90°C, 80°C, 70°C, 60°C, 70°C, The extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com