Novel connected node of cold-formed square tubular columns and H-shaped steel beam and assembly method thereof

A technology for square steel pipes and H-beams, applied in new nodes, new nodes and their assembly fields, can solve problems such as cumbersome processing technology, and achieve the effects of strong on-site operability, clear node force transmission, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

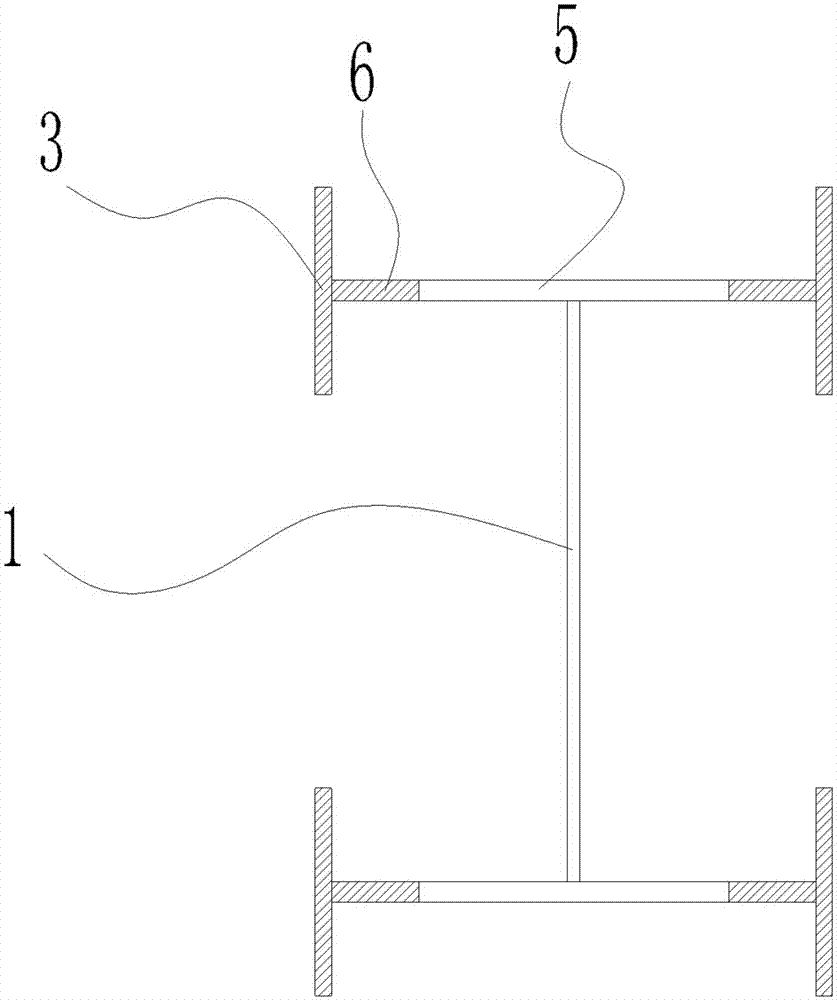

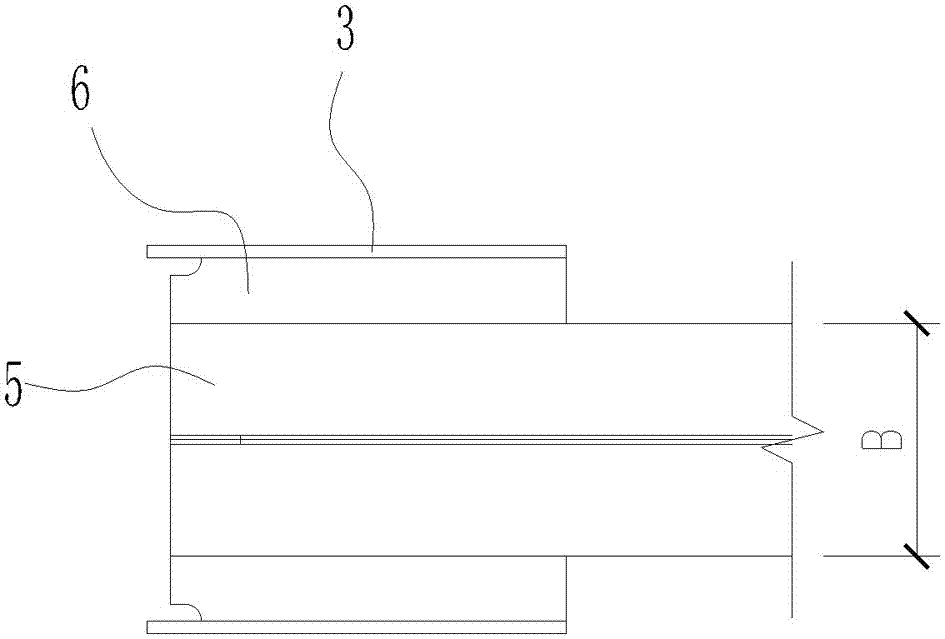

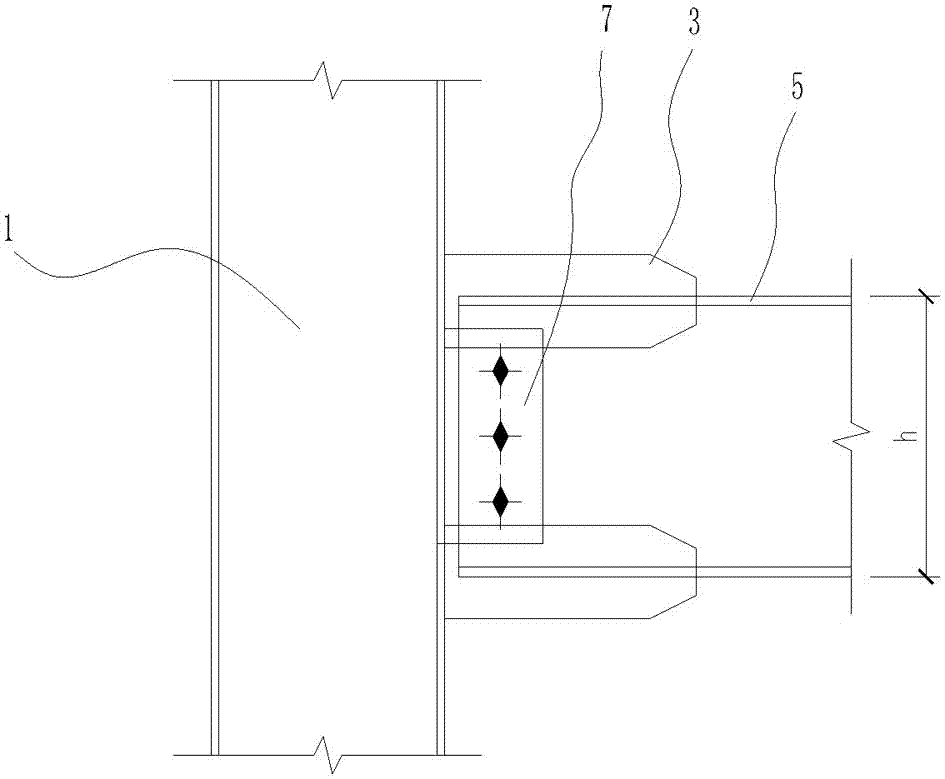

[0034] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a new type of joint between cold-formed square steel pipe columns and H-shaped steel beams, including cold-formed square steel pipe columns 1 and H-shaped steel beam webs 2, the two sides of the H-shaped steel beam webs 2 Connecting components are respectively provided, and the two ends of the connecting components are respectively provided with T-shaped connecting plate flanges 3, and the outer wall of the connecting components is provided with cold-formed square steel pipe columns 1;

[0035] The connecting assembly includes T-shaped steel beam flanges 5 arranged on both sides of the H-shaped steel beam web 6, the outer edge of the T-shaped steel beam flange 5 is provided with a T-shaped connecting plate web 6, and the T-shaped The connecting plate flange 3 is fixedly connected with the T-shaped connecting plate web 6, the T-shaped steel beam flange 5 is vertically distributed with the cold-fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com