Blast-furnace process feeding equipment

A technology of feeding equipment and blast furnace smelting, applied in the direction of bell and funnel arrangement, etc., can solve the problems of low input efficiency of feeding equipment, difficulty in improving the heating efficiency of smelting raw materials, and easy adhesion of smelting raw materials on the wall of feeding equipment, etc. To achieve the effect of ensuring the output rate and preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

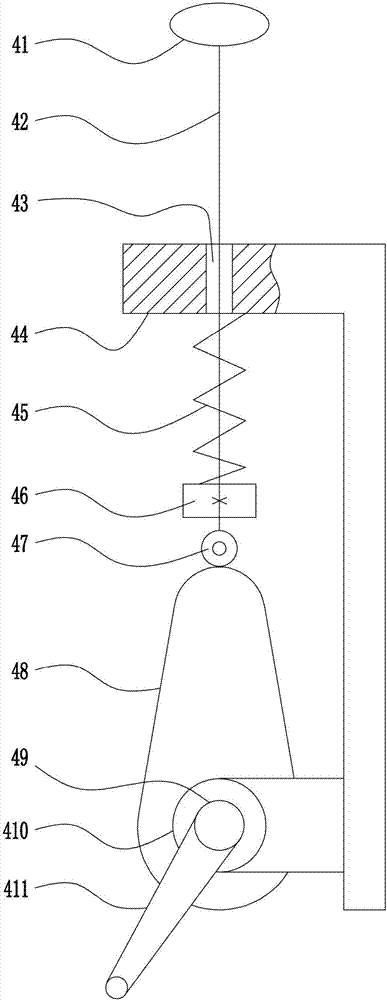

[0031] A blast furnace smelting feeding equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a heating box 2, a heating pot 3, a vibration device 4, a feed hopper 5, a crushing device 6 and a top bracket 7. Bracket 7, the lower end of the left side of the top bracket 7 is provided with a crushing device 6, the lower end of the right side of the top bracket 7 is connected with a heating box 2, a heating pot 3 is arranged above the heating box 2, and a feeding hopper 5 is arranged on the upper left side of the heating pot 3. The feeding hopper 5 is arranged below the pulverizing device 6 and above the vibrating device 4 .

Embodiment 2

[0033] A blast furnace smelting feeding equipment, such as Figure 1-5As shown, it includes a bottom plate 1, a heating box 2, a heating pot 3, a vibration device 4, a feed hopper 5, a crushing device 6 and a top bracket 7. Bracket 7, the lower end of the left side of the top bracket 7 is provided with a crushing device 6, the lower end of the right side of the top bracket 7 is connected with a heating box 2, a heating pot 3 is arranged above the heating box 2, and a feeding hopper 5 is arranged on the upper left side of the heating pot 3. The feeding hopper 5 is arranged below the pulverizing device 6 and above the vibrating device 4 .

[0034] The vibrating device 4 includes a vibrating hammer 41, a lifting rod 42, an L-shaped guide plate 44, a first elastic member 45, a block 46, a contact wheel 47, a cam 48, a first rotating shaft 49, a first bearing seat 410 and a handle 411, The left end of the bottom plate 1 top is connected with an L-shaped guide plate 44, and the top...

Embodiment 3

[0036] A blast furnace smelting feeding equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a heating box 2, a heating pot 3, a vibration device 4, a feed hopper 5, a crushing device 6 and a top bracket 7. Bracket 7, the lower end of the left side of the top bracket 7 is provided with a crushing device 6, the lower end of the right side of the top bracket 7 is connected with a heating box 2, a heating pot 3 is arranged above the heating box 2, and a feeding hopper 5 is arranged on the upper left side of the heating pot 3. The feeding hopper 5 is arranged below the pulverizing device 6 and above the vibrating device 4 .

[0037] The vibrating device 4 includes a vibrating hammer 41, a lifting rod 42, an L-shaped guide plate 44, a first elastic member 45, a block 46, a contact wheel 47, a cam 48, a first rotating shaft 49, a first bearing seat 410 and a handle 411, The left end of the bottom plate 1 top is connected with an L-shaped guide plate 44, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com