Stone surface protective coating and preparation method thereof

A protective coating and stone technology, applied in the direction of coating, etc., can solve the problems that affect the decorative effect and service life, damage the surface gloss of stone, rust spots, etc., achieve good economic benefits and application prospects, block water migration, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

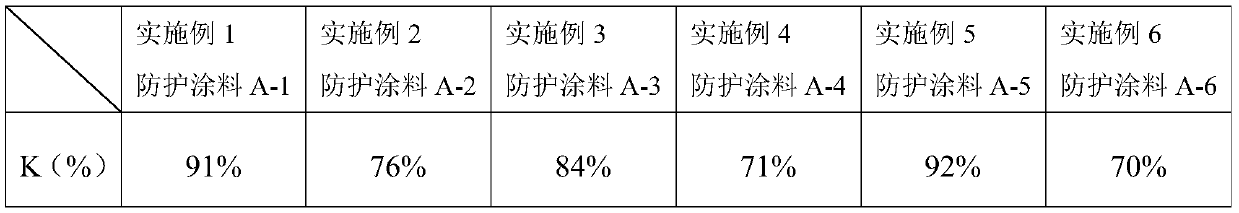

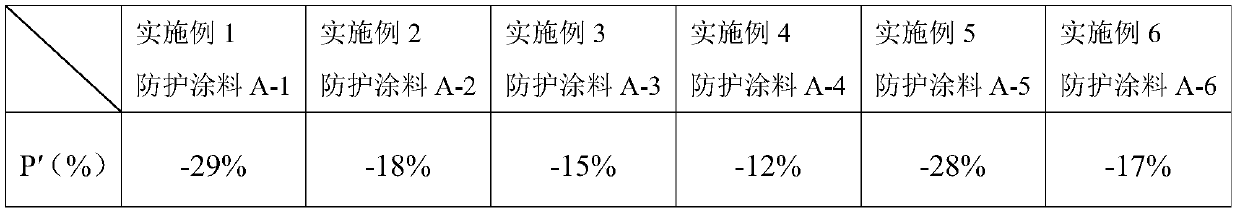

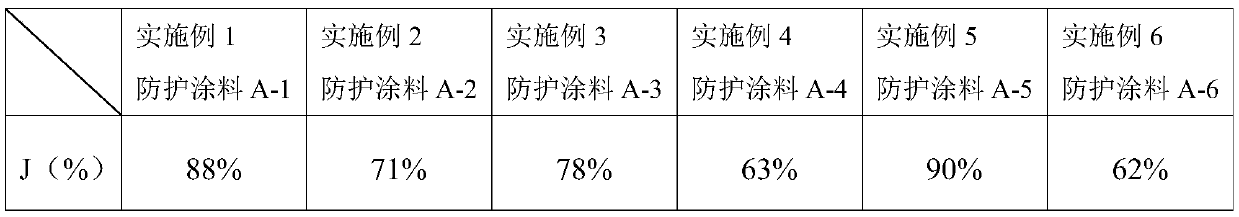

Embodiment 1

[0029] Take 1000g of cyclohexane and 12g of triethylene glycol methyl ether, after mixing, add 45g of nano-silica (particle size 150-200nm), stir for 30min (stirring speed 500r / min), and then add 155g of vinyl-terminated dimethyl base siloxane, mix well, and let it stand for 12h; then, add 5g perfluoromethyl vinyl ether and 45g polystyrene-polybutadiene-polystyrene block copolymer, mix well, and obtain the present invention Stone surface protective coating A-1.

Embodiment 2

[0031] Take 1000g of cyclohexane and 10g of triethylene glycol methyl ether, after mixing, add 52g of nano-silica (particle size 150-200nm), stir for 30min (stirring speed 800r / min), then add 98g of vinyl-terminated dimethyl base siloxane, mix well, and let it stand for 2h; then, add 8g perfluoromethyl vinyl ether and 50g polystyrene-polybutadiene-polystyrene block copolymer, mix well, and obtain the present invention Stone surface protective coating A-2.

Embodiment 3

[0033] Take 1000g of cyclohexane and 10g of triethylene glycol methyl ether, after mixing, add 55g of nano-silica (particle size 150-200nm), stir for 30min (stirring speed 1000r / min), then add 125g of vinyl-terminated dimethyl base siloxane, mix well, and let it stand for 6h; then, add 10g perfluoromethyl vinyl ether and 40g polystyrene-polybutadiene-polystyrene block copolymer, mix well, and obtain the present invention Stone surface protective coating A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com