Cloth cover foam eliminating device of electronic grade glass fiber cloth

A technology of glass fiber cloth and electronic grade, which is applied in the field of cloth surface foam elimination device of electronic grade glass fiber cloth. The effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

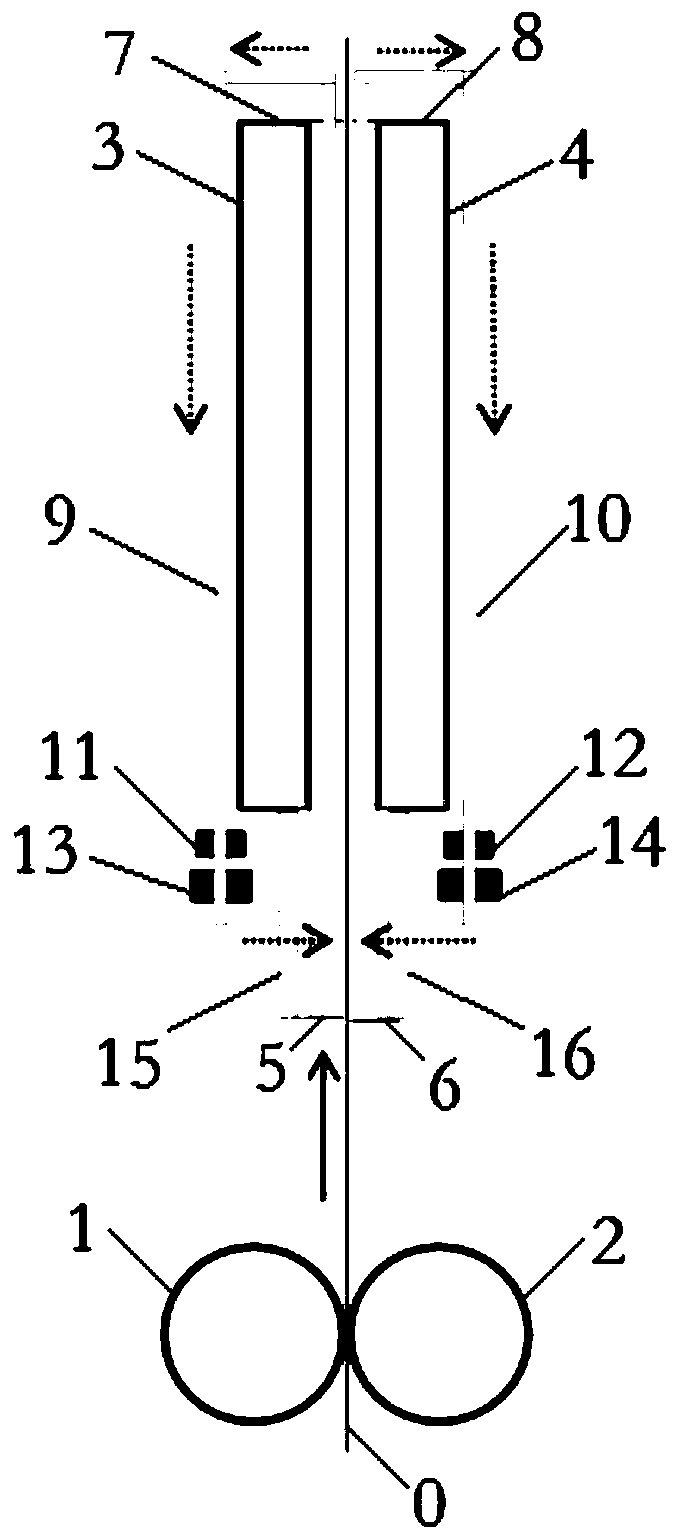

[0029] Such as figure 2 As shown, on the basis of the prior art, the electronic-grade glass fiber cloth surface foam elimination device of this embodiment adds a ventilation pipe, a blower fan, a hot blast stove and a ventilation plate connected in sequence. Wherein, the ventilation pipe is arranged symmetrically on the outside of the drying furnace, and the ventilation pipe is a pipe through which the hot air passes, thereby playing the role of transporting the hot air. The ventilation pipe includes a first ventilation pipe 9 and a second ventilation pipe 10 , the upper end of the first ventilation pipe 9 communicates with the first drying furnace 3 , and the upper end of the second ventilation pipe 10 communicates with the second drying furnace 4 .

[0030] Fans are arranged symmetrically on the lower side of the ventilation pipe to adjust the wind speed. The blower includes a first blower 11 and a second blower 12 , the first blower 11 is located at the lower end of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com