Medicine bottled processing device

A technology for processing devices and medicines, applied in household components, household appliances, other household appliances, etc., can solve the problems of difficult decomposition, non-separation, and difficult degradation, and achieve quick results, reduce power consumption and labor, and facilitate operation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

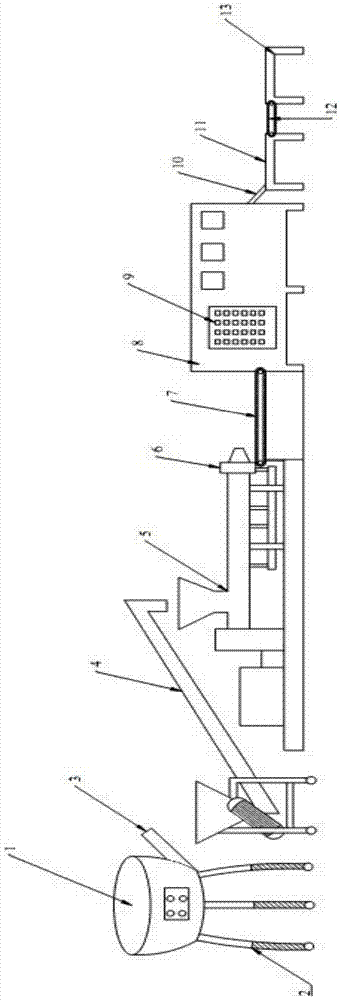

[0017] Such as figure 1 Shown: medicine bottle processing device, its structure includes: mixer 1, bracket 2, discharge port 3, feeder 4, plastic extruder 5, mold 6, conveyor belt 1 7, blow molding machine 8, controller 9. Discharge platform 10, inspection platform 11, conveyor belt second 12, packaging platform 13; mixer 1 is a cylindrical hollow body, the bottom of the mixer 1 is connected to the bracket 2 by welding, and the bottom end of one side of the mixer 1 is welded to the One end of the discharge port 3 is connected, the other end of the discharge port 3 corresponds to the feeder 4 hopper, the other end of the feeder 4 corresponds to the entrance of the plastic extruder 5, and the other port of the plastic extruder 5 is welded with A mold 6, the hinge shaft of the lower end surface of the mold 6 is provided with a conveyor belt first 7, and the other end hinge shaft of the conveyor belt 7 is connected to a blow molding machine 8, and the blow molding machine 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com