Efficient mixing system conducive to mixing denitration

A hybrid system and high-efficiency technology, applied in the field of SCR denitrification system, can solve the problems of NH3 and NOX mismatch, air preheater clogging, denitrification efficiency decline, etc., to reduce ammonia escape, improve turbulence, and save catalyst consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

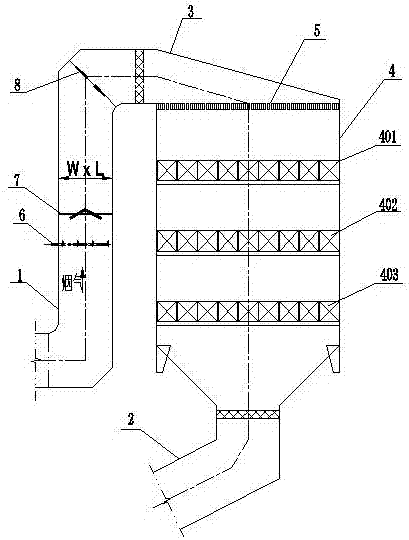

[0042] Project overview: Transformation of SCR denitrification ultra-low emission project, transformation of 2×600MW coal-fired units, entrance NO X Concentration 400mg / Nm 3 , the original design efficiency is 80%, requiring denitrification outlet NO X Concentration≤50mg / Nm 3 , Ammonia escape ≤ 3ppm, SO 2 / SO 3 Conversion rate ≤ 1.5%.

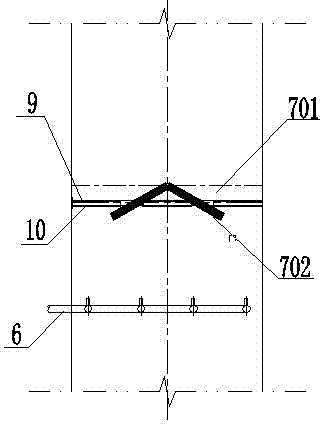

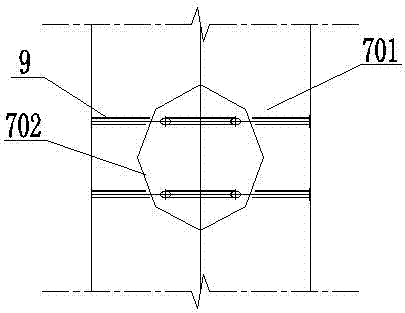

[0043] Arrangement: Double reactors, conventional 2+1 arrangement, two layers of honeycomb catalysts are initially installed, and the conventional design method is adopted, and a commonly used circular vortex mixing device is installed above the ammonia injection grid.

[0044] After it was put into operation, problems were found: two layers of catalysts were initially installed, the design efficiency was 80%, and the performance was up to standard. The maintenance cycle of the air preheater was controlled at about 9 months. At the end of 2014, a spare layer of catalysts was added to improve the efficiency, and NOx was required to be denitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com