Bacterial cellulose-chitosan-laponite compound wound dressing and preparation method thereof

A technology of bacterial cellulose and wound dressing, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of ineffective prevention of wound fat liquefaction, poor moisture absorption and breathability, and low smoothness of wound surface, so as to promote growth, differentiation and epithelial Cell crawling, avoiding secondary damage, and reducing the effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

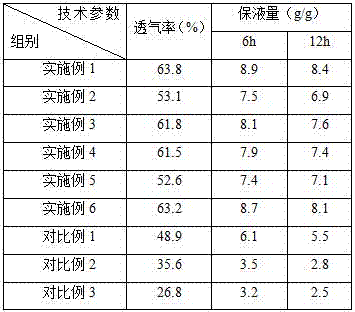

Examples

preparation example Construction

[0029] Found through a large number of experiments by the inventor, the preferred preparation method of the bacterial cellulose-chitosan-lithium compound wound dressing comprises the following steps:

[0030] S1. Soak the bacterial cellulose in pure water, change the pure water 1-3 times during the period, then take it out and dry it at 37-45°C;

[0031] S2. preparing an aqueous acetic acid solution, adding the chitosan and sodium carboxymethyl cellulose, dissolving and mixing; soaking the bacterial cellulose treated in step S1 in the above solution, stirring to reach equilibrium, and freeze-drying;

[0032] S3. prepare lithium alginate aqueous solution, add sodium pyrophosphate, mix and add the product of step S2, soak, stir to reach equilibrium, and freeze-dry to obtain the bacterial cellulose-chitosan-lithium diatomite composite wound dressing.

[0033] Bacterial cellulose-chitosan-lectorite composite wound dressing of the present invention is prepared according to the abov...

Embodiment 1

[0037] A bacterial cellulose-chitosan-lithium composite wound dressing, which is formed by sequential crosslinking of chitosan and lithium celite on the bacterial cellulose; the quality of the bacterial cellulose, chitosan, and lithium The ratio is 6:2:15.

[0038] The preparation method of above-mentioned compound wound dressing, comprises the steps:

[0039] S1. Soak bacterial cellulose in a large amount of pure water for 4 hours, replace the pure water twice during the period, then take it out and dry it in an oven at 40°C for 12 hours;

[0040] S2. Prepare 100ml of 2% acetic acid aqueous solution, add 2g chitosan and 0.8g sodium carboxymethylcellulose, dissolve and mix; soak 6g of the bacterial cellulose treated in step S1 in the above solution, and stir for 3h Equilibrium, freeze-dried;

[0041] S3. The preparation concentration is 100ml of 15% lithium aqueous solution, add 0.5g sodium pyrophosphate, add the product of step S2 after mixing, soak, stir for 3h to reach eq...

Embodiment 2

[0044] The present embodiment is substantially the same as Example 1, and the bacterial cellulose is 6g. The difference is that the mass ratio of the bacterial cellulose, chitosan, and lithium diatomaceous earth is 6:3:12, and the shell in the acetic acid aqueous solution The mass fraction of polysaccharide is 3%, and the mass ratio of chitosan and sodium carboxymethyl cellulose is 5:2; The mass ratio is 30:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com