Method for preparing ultra-low pressure contamination-resistance composite reverse osmosis membrane using chitosan

A technology of reverse osmosis membrane and chitosan, applied in semipermeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problem of loss of protective layer, limited use range, operating pressure of reverse osmosis membrane low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

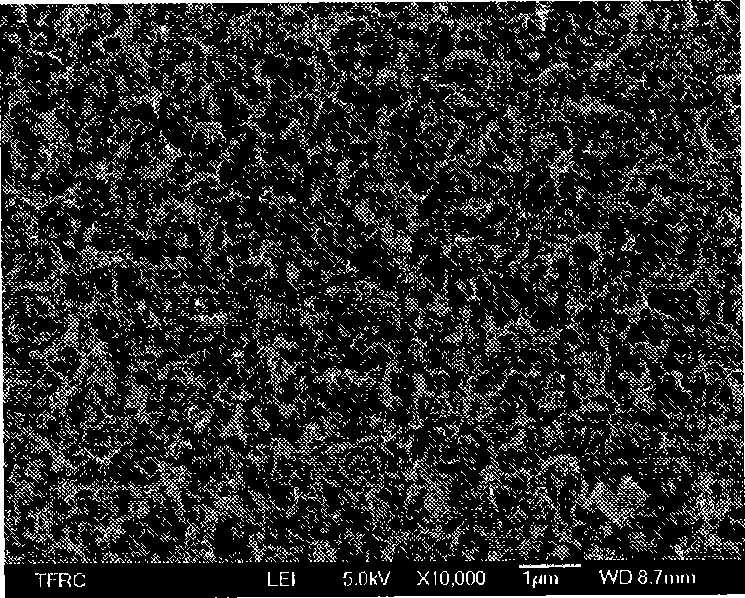

Image

Examples

Embodiment 1

[0025] Dissolve chitosan with a degree of deacetylation greater than 90% in acetic acid, stir at 50°C for 1 h, filter to remove solid impurities in the solution after standing, and configure a solution with a mass concentration of 2%; 2% glutaraldehyde solution and 1% hydrochloric acid were stirred and mixed at a molar ratio of glutaraldehyde to HCl of 1:1 to form solution B. Mix A and B solutions according to the mass ratio of chitosan and glutaraldehyde in a ratio of 4:1 for cross-linking, and then coat it on a polyamide membrane (Toray UTC-70UB) and place it at 100°C for 5 minutes The resulting membrane was preserved in 0.1% sodium bisulfite (SBS) solution.

[0026] For the performance evaluation of the reverse osmosis membrane prepared by the above method, the measured contact angle is 22°, and the water flux of the membrane is measured by using 1500ppm sodium chloride solution at 25°C, 0.75MPa, and a pH value of 7. 1.07m 3 / m 2 d, the salt cut-off rate is 99.5%, then a...

Embodiment 2

[0028] Except that maleic acid is selected as the crosslinking agent, other preparation processes are the same as in Example 1.

[0029] The measured film contact angle was 23°. The performance of the film in Example 2 was evaluated under the same conditions as in Example 1. The obtained properties are shown in Table 1 below.

Embodiment 3

[0031] Except that the mass ratio of chitosan and cross-linking agent is changed into 1:1, other conditions are identical with embodiment 1.

[0032] The measured contact angle of the film was 20°. The performance evaluation of the film of Example 3 was performed under the same conditions as in Example 1, and the results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com