Wire rod having enhanced strength and impact toughness and preparation method for same

A technology of impact toughness and manufacturing methods, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., to achieve the effects of omitting heat treatment process, excellent strength and impact toughness, and reducing overall manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

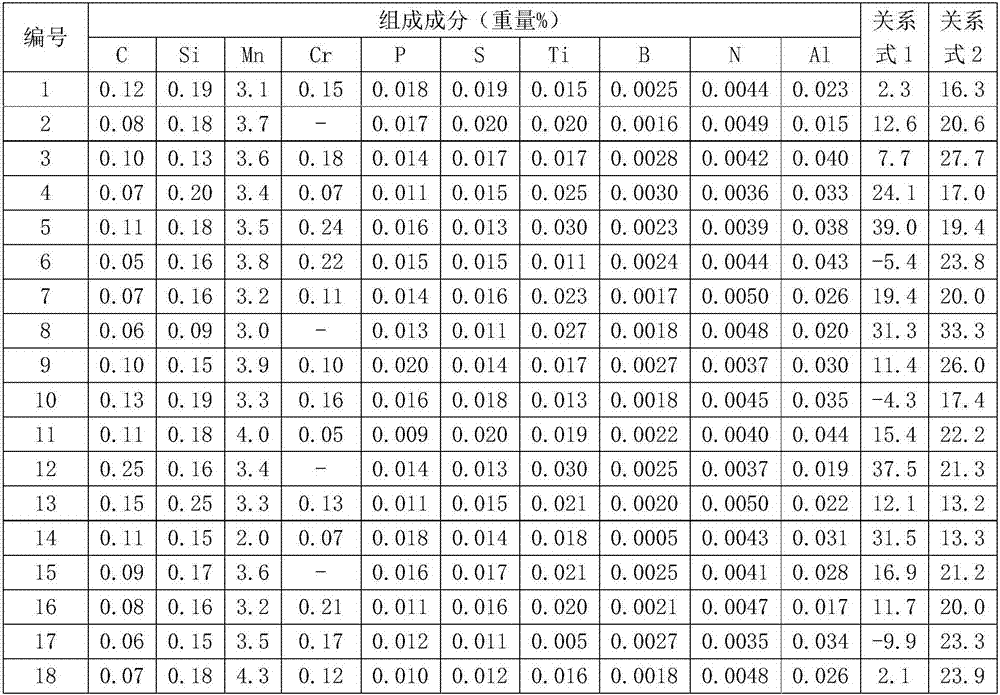

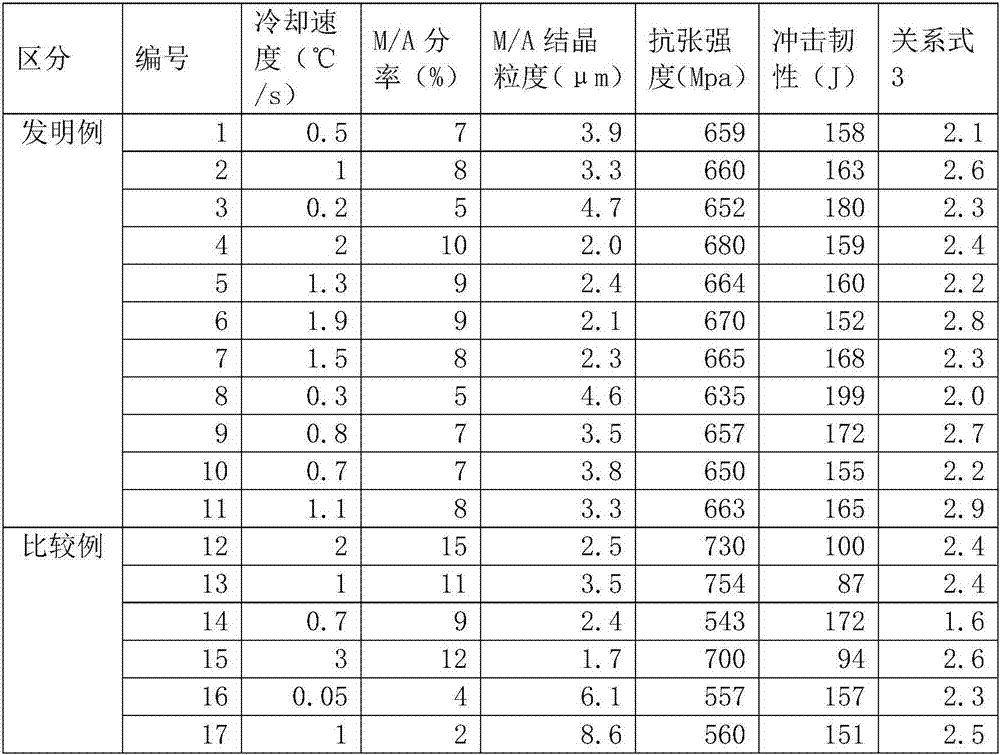

[0075] Next, embodiments of the present invention will be described in detail. The following examples are only for understanding the present invention, and the present invention is not limited by the examples.

[0076] (Example)

[0077] Cast molten steel having the composition shown in Table 1 below, then reheat at 1100°C, then roll the wire rod to a diameter of 15 mm, cool it to 300°C below the Bf temperature at the cooling rate shown in Table 2, and then air-cool it to manufacture wire. In addition, Bf, which is the bainite transformation termination temperature, is measured with a dilatometer, and the range is 300 to 350° C. depending on the chemical composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com