Battery cell hole ironing mechanism and winder thereof

A battery core and hole-scalding needle technology is applied in the field of a battery-core hole-scalding mechanism and its winding machine, which can solve the problems of deformation and rebound of the center reaming hole, low production efficiency, etc. The effect of diaphragm rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

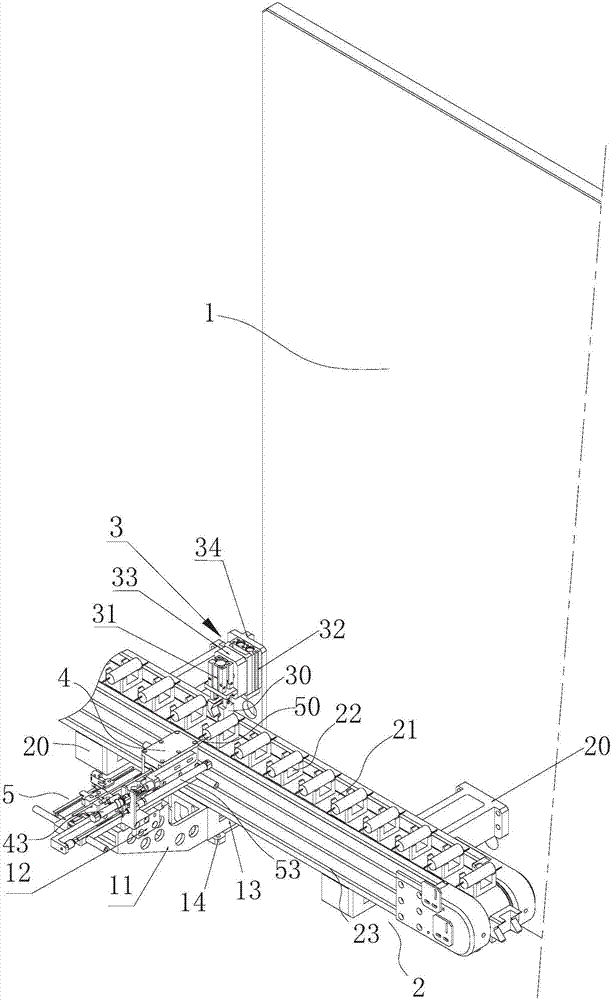

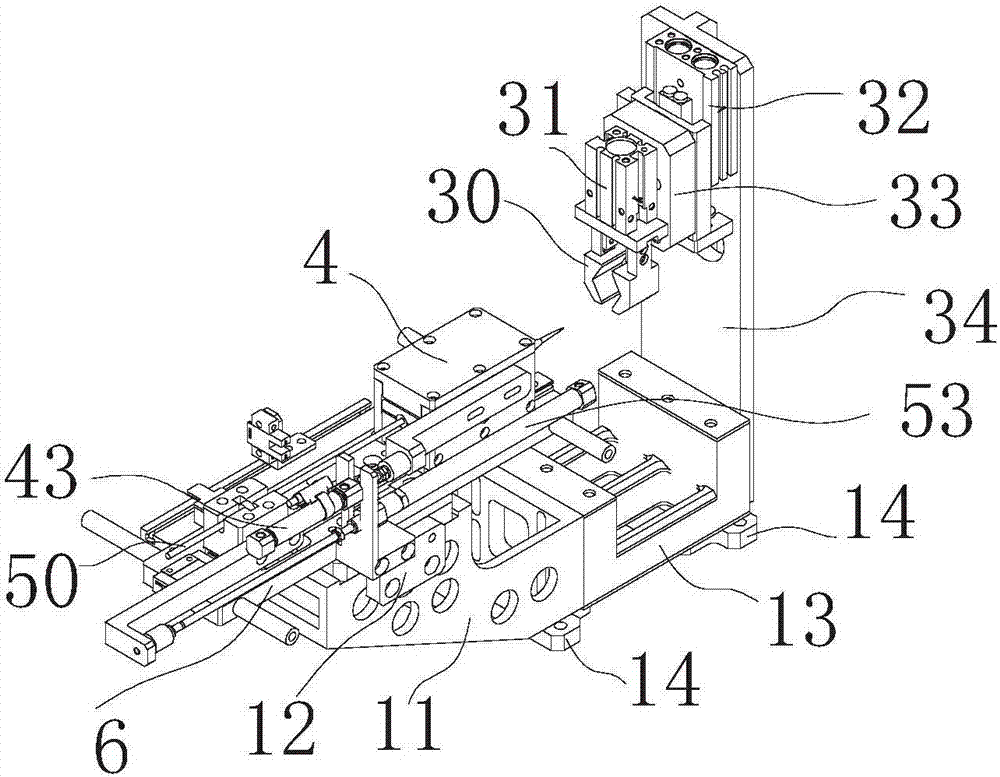

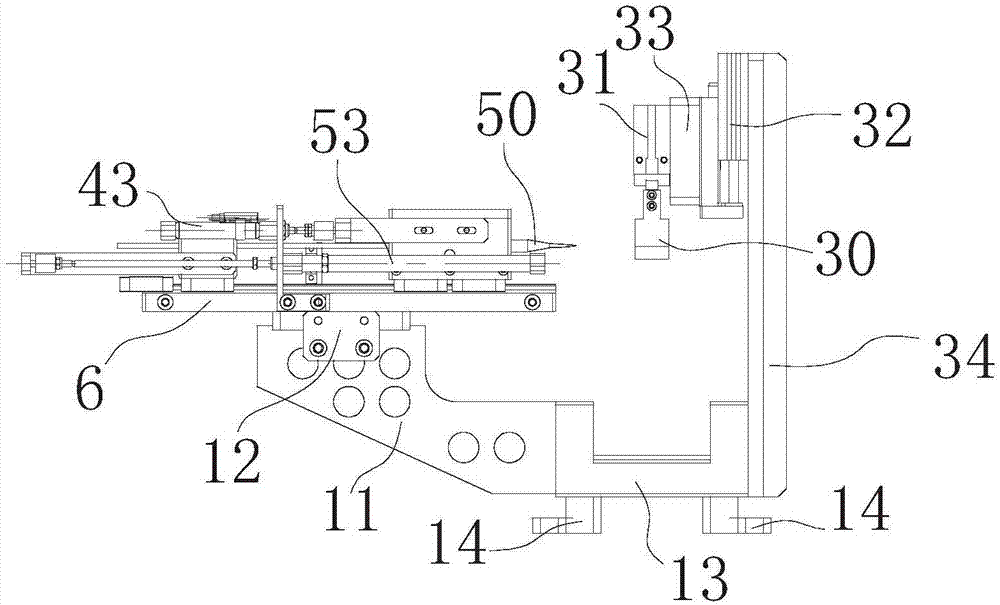

[0036] The core ironing mechanism is mainly used in cylindrical lithium-ion battery automatic winding machines or cylindrical lithium-ion film making and winding integrated machines, such as Figure 1 to Figure 8 As shown, it includes a vertically arranged substrate 1, and a cell conveying part 2 is provided on the front side of the substrate to convey the cylindrical cells wound by the winding machine one by one, and the substrate 1 is also provided with a cell conveying unit. The cell clamping and positioning part 3 for clamping and positioning each cell conveyed on part 2, the ironing needle heating part 4, and the center ironing round hole processing for each cell clamped and fixed by the cell clamping and positioning part 3 The ironing needle feeding part 5 of the ironing needle; after passing through the electric core ironing mechanism, the electric core that originally passed through the reamed hole is ironed by the heated ironing needle, so that the center hole of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com