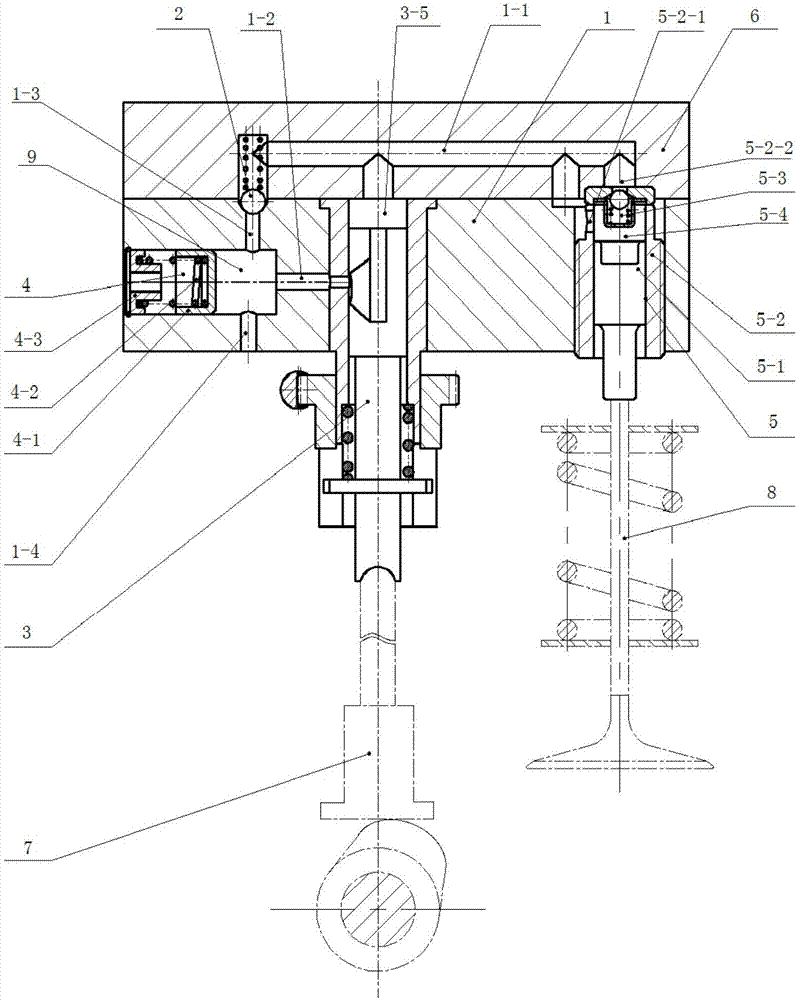

Valve lift control device of fully variable hydraulic valve mechanism and internal combustion engine

A valve mechanism and valve lift technology, applied in valve devices, machines/engines, mechanical equipment, etc., can solve the problems of long transmission chain, difficult layout of hydraulic transmission system, etc., and achieve the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

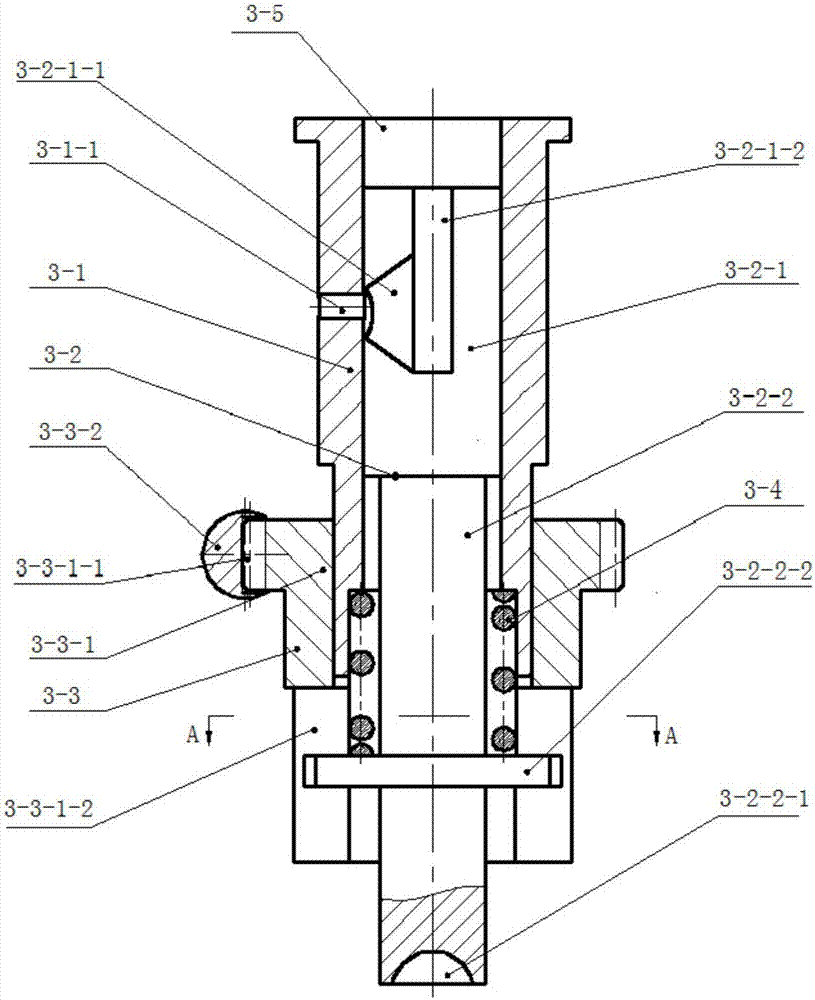

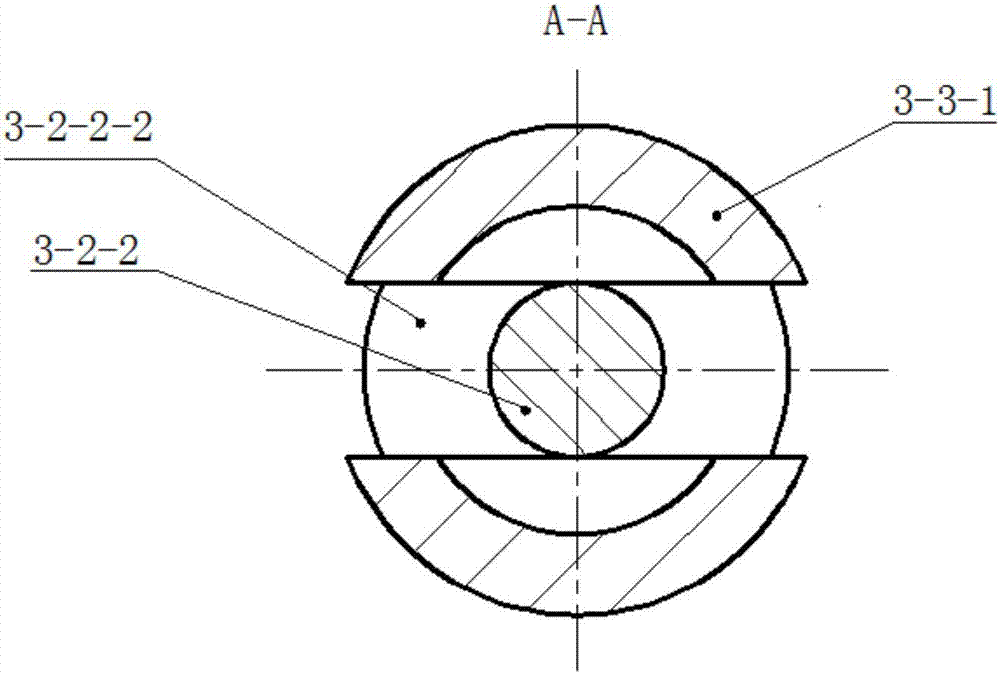

[0058] like Figure 5 As shown, the distance between the upper edge of the circumferential annular groove 3-2-1-1 and the top end of the plunger 3-2 gradually increases from the axial straight groove 3-2-1-2 along the circumferential direction of the plunger 3-2 , the depth of the circumferential annular groove 3-2-1-1 gradually decreases from the axial straight groove 3-2-1-2 along the circumferential direction of the plunger 3-2, and the circumferential annular groove 3-2-1-1 The cross section is triangular.

[0059] In this embodiment, when the required maximum valve lift becomes smaller and the valve closing time is earlier, the plunger adjustment mechanism 3-3 adjusts the rotation angle of the plunger 3-2 so that the circumferential annular groove 3-2-1-1 The part close to the axial straight groove 3-2-1-2 communicates with the oil drain hole 3-1-1, because the distance between the upper edge of this part of the circumferential annular groove 3-2-1-1 and the top of the p...

Embodiment 2

[0061] like Image 6 As shown, the cross section of the circumferential annular groove 3-2-1-1 is arc-shaped, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0063] like Figure 7 As shown, the distance between the upper edge of the circumferential annular groove 3-2-1-1 and the top end of the plunger 3-2 gradually increases from the axial straight groove 3-2-1-2 along the circumferential direction of the plunger 3-2 , the distance from the lower edge to the top of the plunger 3-2 is constant from the axial straight groove 3-2-1-2 along the circumferential direction of the plunger 3-2, and the depth of the circumferential annular groove 3-2-1-1 is constant Change. When the plunger adjustment mechanism 3-3 adjusts the plunger 3-2 to rotate different angles, the timing when the circumferential annular groove 3-2-1-1 communicates with the oil drain hole 3-1-1 is different, so that the plunger oil The moment when the chamber 3-5 and the piston oil chamber 5-4 flow into the energy storage chamber 9 through the oil drain hole 3-1-1 also changes accordingly, causing the maximum lift of the valve to also change thereupon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com