Gas-liquid coupling turbine blade cooling unit

A technology of cooling unit and turbine blade, applied in the direction of blade support element, engine element, machine/engine, etc., can solve the problems of reducing the temperature of aero-engine turbine blades, thermal stress concentration of blades, and strengthening heat conduction, so as to improve the thrust-to-weight ratio. , the effect of increasing the liquid cooling path and increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principle and working process of the present invention will be further described below in conjunction with specific implementation and accompanying drawings.

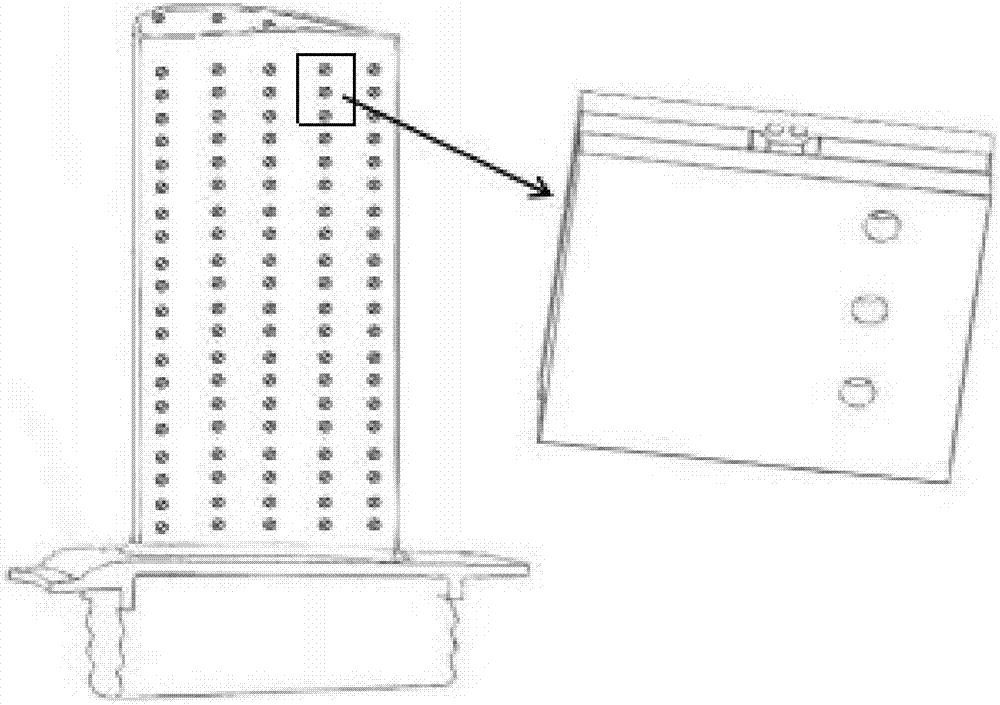

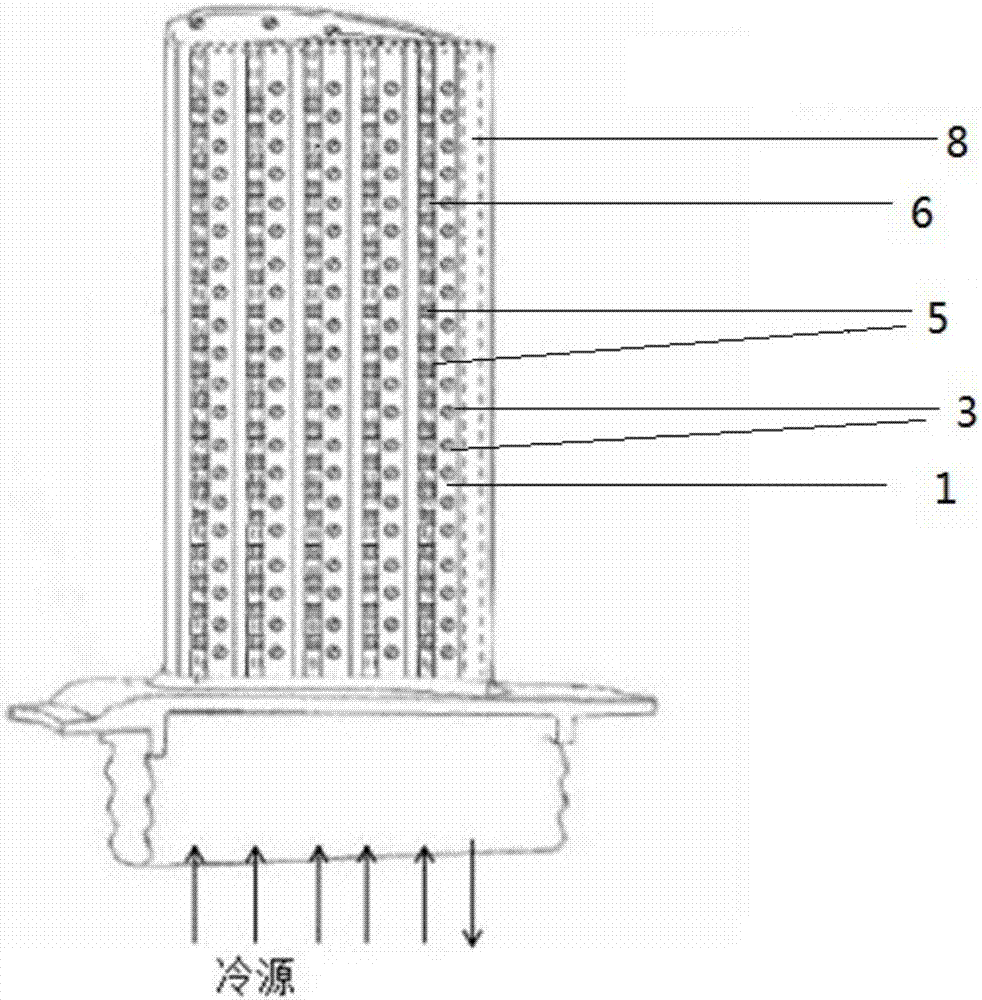

[0030] like figure 1 As shown, the gas-liquid coupling turbine blade cooling unit disclosed in the present invention is a composite cooling structure of "impact / air film / turbulent flow" applied in a double shell type.

[0031] like Figure 2 to Figure 5 As shown, the gas-liquid coupling turbine blade cooling unit structure includes a cold air wall 1, a hot air wall 2, an impact hole 3, an air film hole 4, a spoiler column 5, a receiving platform 6, and a cold source pipeline 7 and other structures.

[0032] like image 3 As shown, the cooling unit in the embodiment has a cold air wall 1 , a hot air wall 2 , and a spoiler column 5 located between the cold air wall 1 and the hot air wall 2 . The cold air wall 1 is provided with multiple sets of impact holes 3 arranged in an array, wherein the multiple impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com