Composite type building framework and manufacturing method thereof

A technology of building formwork and manufacturing method, which is applied to the manufacture of composite building formwork and the field of composite building formwork, can solve the problems of non-conformity with environmental protection construction, affect flatness, and high scrap rate, and achieve easy cleaning and repeated use. The effect of avoiding hot melt adhesive bonding and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

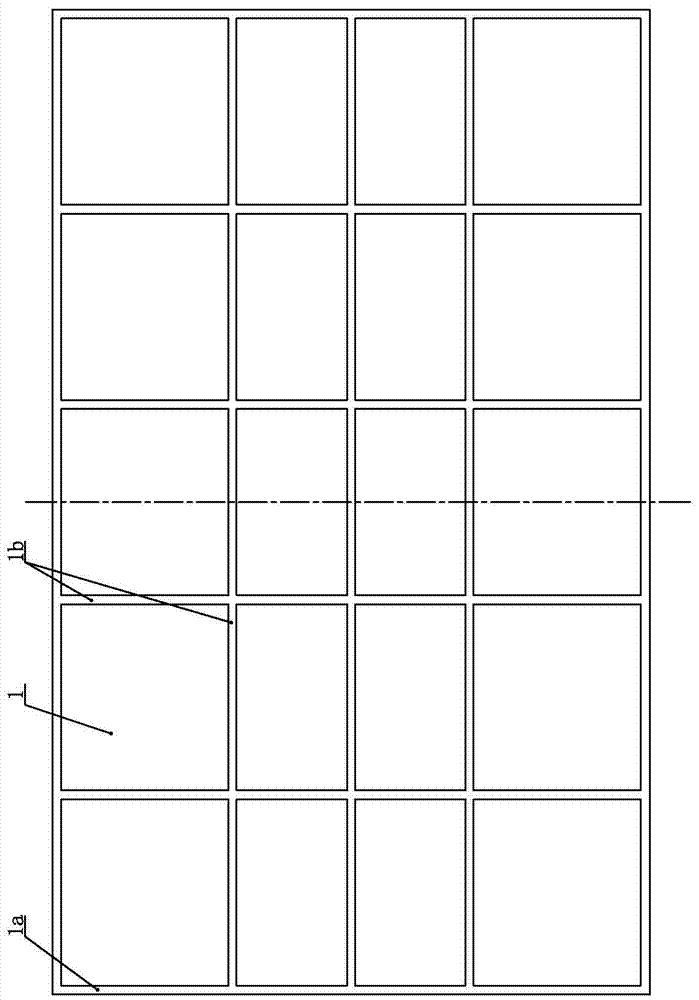

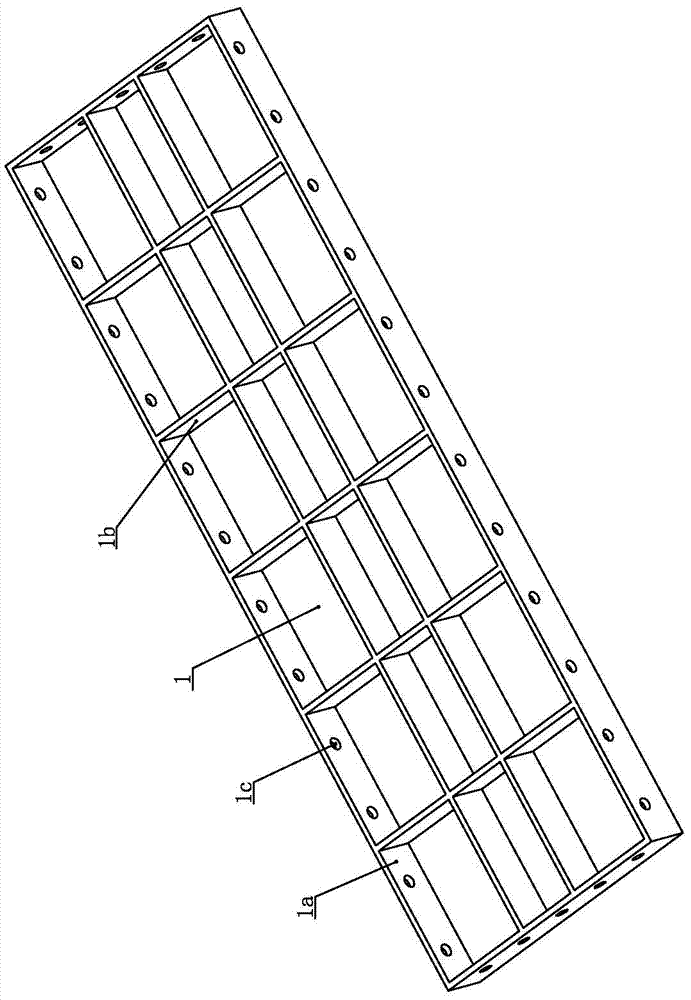

[0024] Such as Figure 1 to Figure 3 As shown, the composite building formwork of the present invention comprises a plastic formwork base material 1, and a PP composite layer sheet 2 is thermally bonded to the working surface of the plastic formwork base material 1, and the PP composite layer sheet material 2 includes a non-woven fabric connected together. Layer 2c, PP compound sheet layer 2b and pure PP film layer 2a, the pure PP film layer 2a is thermally bonded to the upper surface of the PP compound film layer 2b, and the non-woven fabric layer 2c is thermally bonded to the bottom of the PP compound film layer 2b On the surface, the non-woven fabric layer 2c faces the working surface of the plastic formwork substrate 1 and is thermally bonded as a whole.

[0025] The working surface of the plastic formwork base material 1 is the front facing the concrete. When the plastic formwork base material 1 is still in a molten state, it is combined with the PP composite layer sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com