A kind of trichoderma fermentation substrate based on monosodium glutamate waste liquid and its application

A technology of fermentation substrate and monosodium glutamate waste liquid, applied in the direction of microorganism-based methods, applications, fertilizers made from biological waste, etc., can solve the problem of high cost of fermentation substrates, achieve low prices, reduce pollution, and achieve the effects of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Trichoderma fermentation substrate based on monosodium glutamate waste liquid, concentrated with monosodium glutamate waste liquid (glutamic acid mother liquor after monosodium glutamate production), and then adding inorganic nitrogen source, phosphorus source and potassium source, so that the composition of the final fermentation substrate is: Nitrogen 6-7%, phosphorus 2-3%, potassium 0.5-1.0%, organic matter ≥ 35%, pH=6.5-7.0, moisture ≤ 30%. The used glutamic acid mother liquor characteristic of the present invention is: dry basis is 22%, and the composition after being dried is: nitrogen 14%, phosphorus 1.0%, potassium 1.8%, organic matter 48%, Pomi degree is 17 o Be, pH 3.0. The inorganic nitrogen source is ammonium sulfate and ammonium phosphate, the phosphorus source is ammonium phosphate, and the potassium source is potassium chloride.

[0030] Add 30-35 times the mass of distilled water to the above-mentioned fermentation substrate to obtain a liquid medium,...

Embodiment 2

[0035] Obtaining Trichoderma fermentation substrate: a Trichoderma fermentation substrate based on MSG waste liquid, concentrated with MSG waste liquid (glutamic acid mother liquor after MSG production), and then adding ammonium sulfate, ammonium phosphate and potassium chloride and organic matter, The composition of the final fermentation substrate is: 6.4% nitrogen, 2.4% phosphorus, 0.7% potassium, 35% organic matter, pH=6.9, and 30% moisture. The used glutamic acid mother liquor characteristic of the present invention is: dry base is 22%, and the composition after being dried is: total nitrogen 14%, phosphorus 1.0%, potassium 1.8%, organic matter 48%, Pomi degree is 17 o Be, pH 3.0.

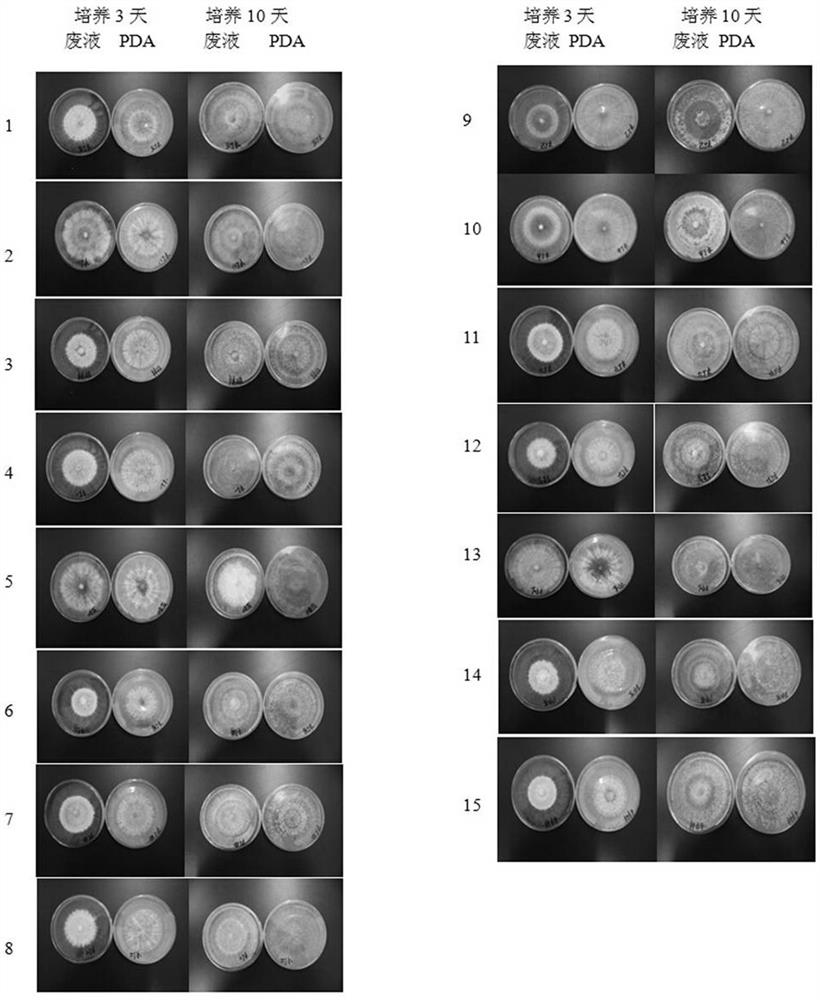

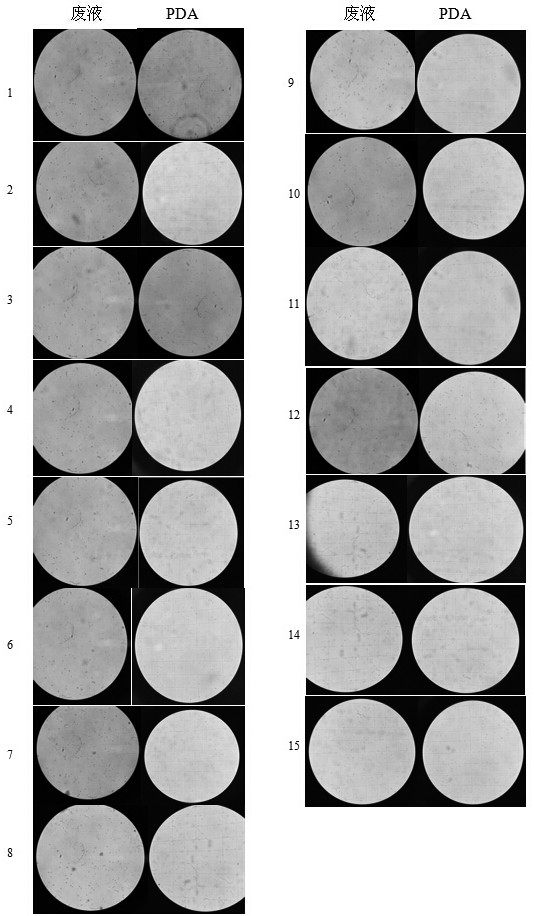

[0036] Preparation of Trichoderma fermentation medium: 30g of culture medium was added to distilled water to make the volume to 1000mL, then 20g of agar was added, and 20mL of medium was poured into a 90mm petri dish to prepare a solid fermentation medium plate.

[0037] Trichoderma inoculati...

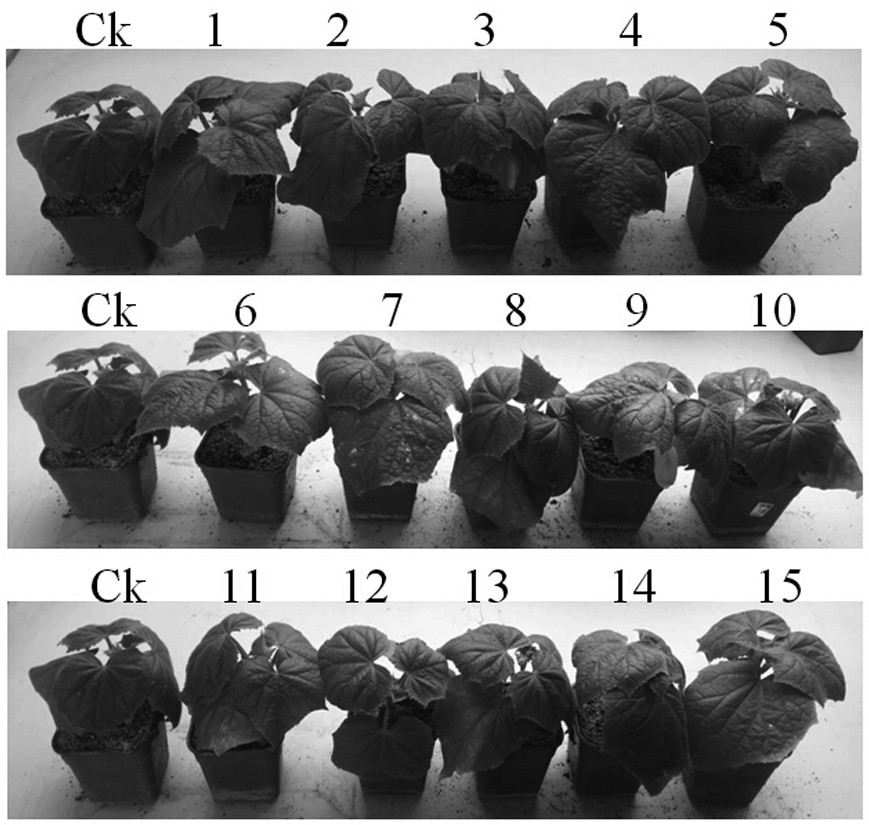

Embodiment 3

[0053] Obtaining Trichoderma fermentation substrate: a Trichoderma fermentation substrate based on MSG waste liquid, concentrated with MSG waste liquid (glutamic acid mother liquor after MSG production), and then adding ammonium sulfate, ammonium phosphate and potassium chloride and organic matter, The composition of the final fermentation substrate is: 6% nitrogen, 2% phosphorus, 0.5% potassium, 35% organic matter, pH=6.5, and 30% moisture. The used glutamic acid mother liquor characteristic of the present invention is: dry basis is 22%, and the composition after being dried is: nitrogen 14%, phosphorus 1.0%, potassium 1.8%, organic matter 48%, Pomi degree is 17 o Be, pH 3.0.

[0054] Preparation of Trichoderma fermentation medium: 33.3 g of culture medium was added with distilled water to make the volume to 1000 mL, then 18 g of agar was added, and 20 mL of medium was poured into a 90 mm petri dish to prepare a solid fermentation medium plate.

[0055] Trichoderma inoculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com