Method for refining cold pressed oil of radish seeds

A refining method and cold-pressed oil technology, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems of long residence time, turbidity of finished oil, and affecting the use effect, so as to achieve good effect, reduce oxidation degree, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

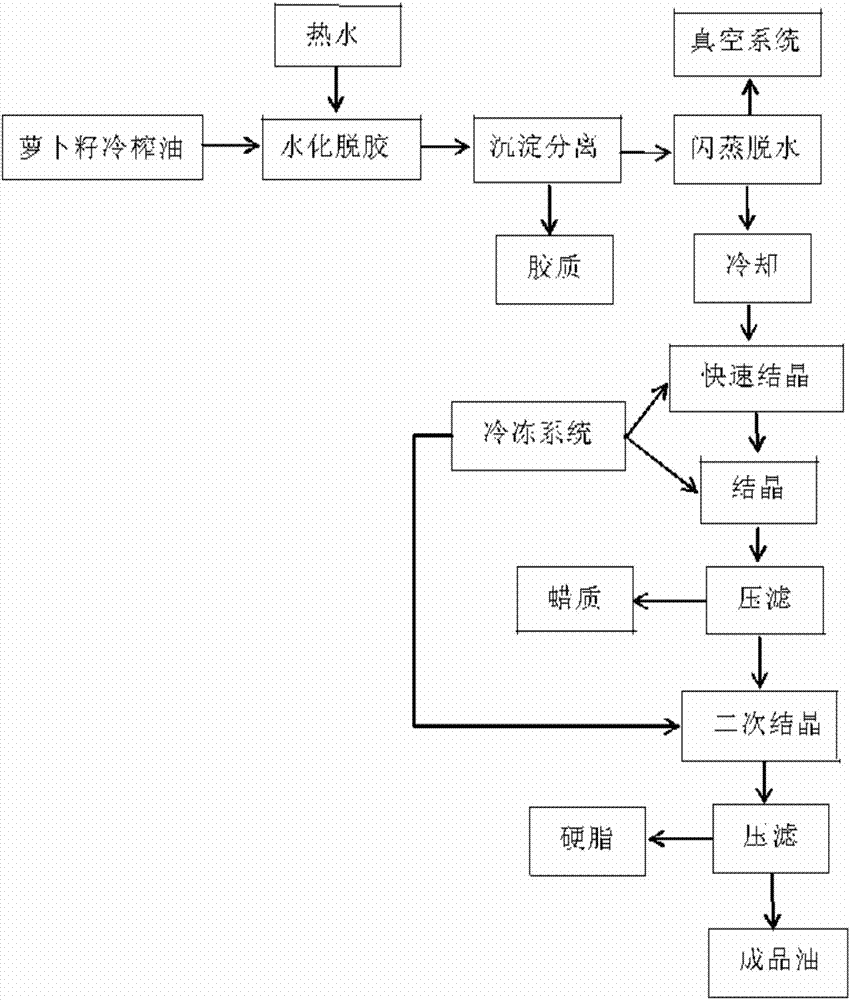

[0021] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 Shown, a kind of refining method of radish seed cold pressing oil, this method comprises the following steps:

[0023] Step 1. Pump the filtered radish seed cold-pressed oil into the hydration tank, and put steam into the heating coil of the hydration tank. The steam pressure does not exceed 0.4Mpa. While heating, turn on the stirring motor and adjust the stirring The rotation speed is 60r / min until the oil temperature reaches 60°C.

[0024] Step 2. Heat the softened water in the hot water tank to 70°C, open the water inlet valve, add hot water to the oil in step 1 according to 4.5% of the oil weight, stir while adding water, and the stirring speed is 60r / min , The time for adding water is 15 minutes. After adding water, continue to stir for 15 minutes, and the stirring speed is 30r / min.

[0025] Step 3, heat the oil in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com