Preparation method of culture medium for cultivating hypsizigus marmoreus

A technology for cultivating materials and shimeji mushrooms, which is applied in fertilizers, applications, and organic fertilizers made of biological waste, can solve problems such as increased cost, low utilization rate, high energy and low yield, etc., to shorten the growth cycle and increase the output. and the effect of quality and nutritional balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

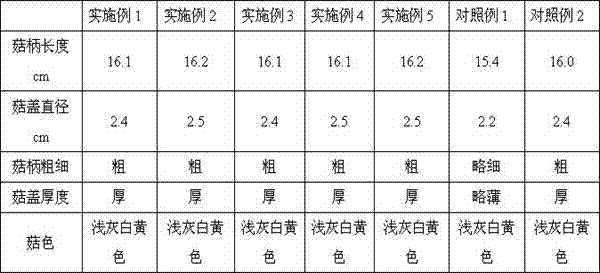

Examples

Embodiment 1

[0027] A preparation method for cultivating a culture medium of shimeji mushroom, comprising the steps of:

[0028] Step 1, by weight, take bagasse 10Kg, peanut shells 10Kg and bamboo chips 10Kg and pulverize to a powder with a diameter of 2mm, put it into 10wt%NaOH solution and soak for 12h, take it out, and dry it to obtain the swelling slag material;

[0029] Step 2, by weight, take 30 Kg of fungus residue, 5 Kg of rapeseed cake, 5 Kg of chicken manure, 20 Kg of wheat straw, 10 Kg of beech sawdust, 1 Kg of fly ash, 10 Kg of water hyacinth, 50 Kg of water and hay 15 Kg of bacillus was mixed evenly with the swelling slag material, put into the fermentation tank, covered with a film, and carried out fermentation treatment, the fermentation time was 18 days, and fermented fertilizer was obtained;

[0030] Step 3, mix the fermented fertilizer with 10 Kg of urea, 15 Kg of potassium phosphate, 7 Kg of lime powder, 3 Kg of ammonium lignosulfonate, 7 Kg of zeolite powder, 4 Kg of hu...

Embodiment 2

[0033] A preparation method for cultivating a culture medium of shimeji mushroom, comprising the steps of:

[0034] Step 1, by weight, take 30 Kg of bagasse, 20 Kg of peanut shells and 20 Kg of bamboo chips and pulverize to a powder with a diameter of 2mm, put it into 10wt% NaOH solution and soak for 24h, take it out, dry it, and obtain the swelling slag material;

[0035] Step 2, by weight, take 50 Kg of fungus residue, 12 Kg of rapeseed cake, 10 Kg of chicken manure, 35 Kg of wheat straw, 20 Kg of beech sawdust, 3 Kg of fly ash, 18 Kg of water hyacinth, 100 Kg of water and 25 Kg of Bacillus subtilis was mixed evenly with the swelling slag material, put into the fermentation tank, covered with a film, and fermented, and the fermentation time was 21 days to obtain fermented fertilizer;

[0036] Step 3, mix the fermented fertilizer with 10 Kg of urea, 15 Kg of potassium phosphate, 7 Kg of lime powder, 3 Kg of ammonium lignosulfonate, 7 Kg of zeolite powder, 4 Kg of humic acid a...

Embodiment 3

[0039] A preparation method for cultivating a culture medium of shimeji mushroom, comprising the steps of:

[0040] Step 1, by weight, take 22Kg of bagasse, 13Kg of peanut shells and 15Kg of bamboo chips and pulverize them to a powder with a diameter of 2mm, put them into a 10wt% NaOH solution and soak for 18h, take them out, and dry them to obtain the swelling slag material;

[0041] Step 2, by weight, take 42Kg of fungus residue, 9Kg of rapeseed cake, 8Kg of chicken manure, 28Kg of wheat straw, 15Kg of beech sawdust, 2Kg of fly ash, 15Kg of water hyacinth, 77Kg of water, 21Kg of Bacillus licheniformis and swelling slag material Mix evenly, put it into a fermentation tank, cover with film, and carry out fermentation treatment. The fermentation time is 18 days to obtain fermented fertilizer;

[0042] Step 3, mix the fermented fertilizer with 8Kg of urea, 8Kg of potassium phosphate, 5Kg of lime powder, 2Kg of ammonium lignosulfonate, 5Kg of zeolite powder, 3Kg of humic acid and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com