Method for preparing brick from sludge anaerobic digestion biogas residues

A technology of anaerobic digestion and biogas residue, which is applied to clay products, applications, household appliances, etc., and can solve problems such as poor sludge stability, incomplete reduction, and groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

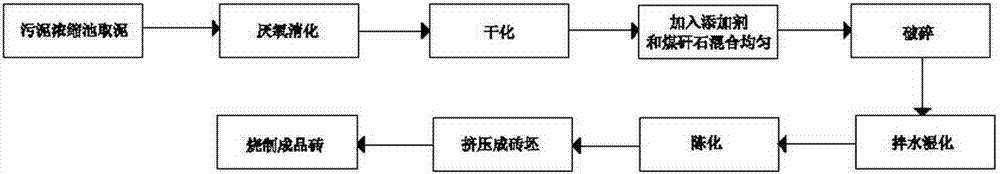

Image

Examples

Embodiment 1

[0017] Sludge from a thickening tank of a sewage treatment plant in Zhengzhou City. The plant mainly treats municipal domestic sewage. The sludge in the thickening tank is dark brown and has an odor. The pH is 6.8 and the MLVSS is 57%. The fly ash is taken from a nearby thermal power plant. Coal gangue is a commercially available product.

[0018] The method for making bricks from sludge anaerobic digestion biogas residues comprises the following steps:

[0019] (1) Take the mud from the concentration tank of the sewage plant, adjust it to a solid content of 8%, and anaerobically digest it at 36°C for 26 days to obtain sludge with a water content of 65%, and dry the digested sludge to a moisture content of 25%.

[0020] (2) Add additives and coal gangue to the dried biogas residue, the mass ratio of biogas residue, additives and coal gangue is biogas residue: additive: coal gangue 15:1:2, and the additive is powder A mixture of coal ash and kaolin, the mass ratio of the fly ...

Embodiment 2

[0025] Sludge from the thickening tank of a sewage treatment plant in Zhengzhou City. The plant mainly treats municipal domestic sewage. The sludge in the thickening tank is dark brown and has an odor. The pH is 7 and the MLVSS is 59%. The fly ash is taken from a nearby thermal power plant. Coal gangue is a commercially available product.

[0026] The method for making bricks from sludge anaerobic digestion biogas residues comprises the following steps:

[0027] (1) Take the sludge from the sludge thickening tank, adjust it to the sludge with a moisture content of 70% after the high-concentration anaerobic digestion at 37°C for 28 days with a solid content of 9%, and digest the digested sludge Dry to a moisture content of 27%.

[0028] (2) Add additives and coal gangue to the dried biogas residue, the mass ratio of biogas residue, additives and coal gangue is biogas residue: additive: coal gangue 16:1:3, and the additive is powder A mixture of coal ash and kaolin, the mass r...

Embodiment 3

[0033] Sludge from the thickening tank of a sewage treatment plant in Zhengzhou City. The plant mainly treats municipal domestic sewage. The sludge in the thickening tank is dark brown and has an odor. The pH is 7.2 and the MLVSS is 61%. The fly ash is taken from a nearby thermal power plant. Coal gangue is a commercially available product.

[0034] (1) Take the sludge from the sludge concentration tank, adjust it to a solid content rate of 10%, and digest the sludge with a water content of 75% after high-concentration anaerobic digestion at 38°C for 30 days. Digest the digested sludge The slag is dried to a moisture content of 30%.

[0035] (2) Add additives and coal gangue to the dried biogas residue, the mass ratio of biogas residue, additives and coal gangue is biogas residue: additive: coal gangue 17:1:4, and the additive is powder A mixture of coal ash and kaolin, the mass ratio of the fly ash: kaolin mixture is fly ash: kaolin = 4:1.

[0036] (3) Fully crush the mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com