A kind of preparation method of mesoporous carbon material

A production method and technology of porous carbon, applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of high production cost and difficulty in wide application, achieve environmental stability, improve safety, and good structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

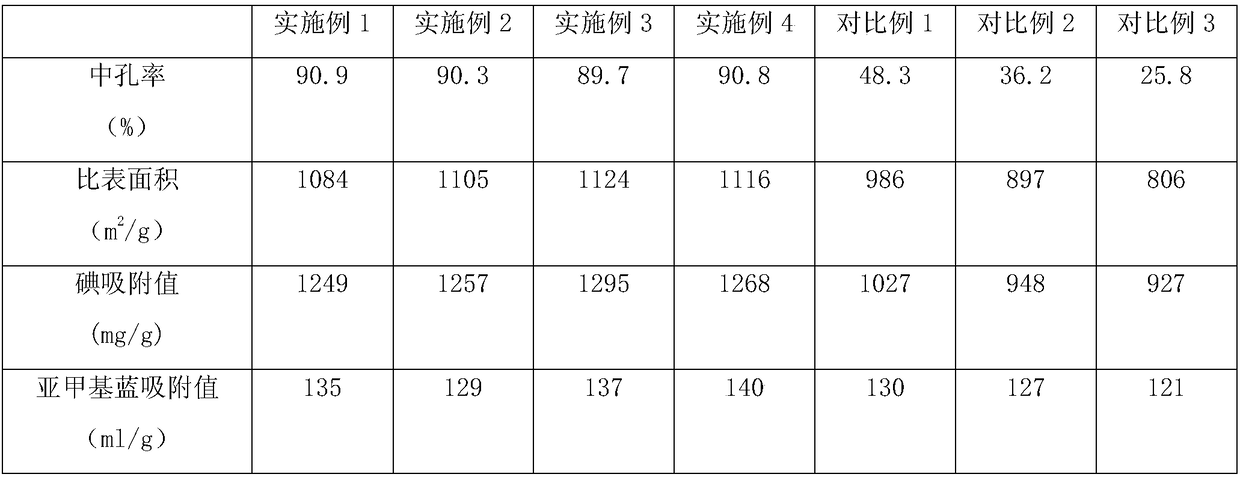

Examples

Embodiment 1

[0023] A method for preparing a mesoporous carbon material, comprising the following steps:

[0024] (1) Raw materials: the main raw materials for making mesoporous carbon materials include activated carbon, and the preparation method of the activated carbon is to mix semi-coke and coconut shells, put the mixture into a pulverizer and pulverize it until the particle size is less than 1mm, to obtain mixture a; mix the mixture a is immersed in a phosphoric acid solution with a mass concentration of 5% for 5 hours, washed with water to neutrality, and then carbonized under a nitrogen atmosphere after drying. The carbonization temperature is 600° C., and the carbonization time is 5 hours to obtain activated carbon; wherein, the The mass ratio of semi-coke and coconut shell is 5:1;

[0025] (2) Impregnation: Mix the activated carbon described in step (1) with the pore-forming agent, impregnate for 2 hours under the condition of ultrasonic vibration, dry at 80-105°C for 10 hours, an...

Embodiment 2

[0030] A method for preparing a mesoporous carbon material, comprising the following steps:

[0031] (1) Raw materials: the main raw materials for making mesoporous carbon materials include activated carbon, and the preparation method of the activated carbon is to mix semi-coke and coconut shells, put the mixture into a pulverizer and pulverize it until the particle size is less than 1mm, to obtain mixture a; mix the mixture a is immersed in a phosphoric acid solution with a mass concentration of 8% for 8 hours, washed with water to neutrality, and then carbonized in a nitrogen atmosphere after drying. The carbonization temperature is 850° C., and the carbonization time is 6 hours to obtain activated carbon; wherein, the The mass ratio of semi-coke and coconut shell is 6:1;

[0032] (2) Impregnation: Mix the activated carbon described in step (1) with the pore-forming agent, impregnate for 4 hours under the condition of ultrasonic vibration, dry at 80-105°C for 12 hours, take ...

Embodiment 3

[0037] A method for preparing a mesoporous carbon material, comprising the following steps:

[0038] (1) Raw materials: the main raw materials for making mesoporous carbon materials include activated carbon, and the preparation method of the activated carbon is to mix semi-coke and coconut shells, put the mixture into a pulverizer and pulverize it until the particle size is less than 1mm, to obtain mixture a; mix the mixture a is immersed in a phosphoric acid solution with a mass concentration of 6% for 6 hours, washed with water to neutrality, and carbonized under a nitrogen atmosphere after drying. The carbonization temperature is 650 ° C, and the carbonization time is 5.2 hours to obtain activated carbon; wherein, The mass ratio of described semi-coke and coconut shell is 5.3:1;

[0039](2) Impregnation: Mix the activated carbon described in step (1) with the pore-forming agent, impregnate for 3 hours under the condition of ultrasonic vibration, dry at 80-105°C for 11 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com