High-speed screening and crushing device for rare earth carbonate

A crushing device, the technology of rare earth carbonate, applied in the direction of filter screen, solid separation, grid, etc., can solve the problem of inability to sieve and crush rare earth carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

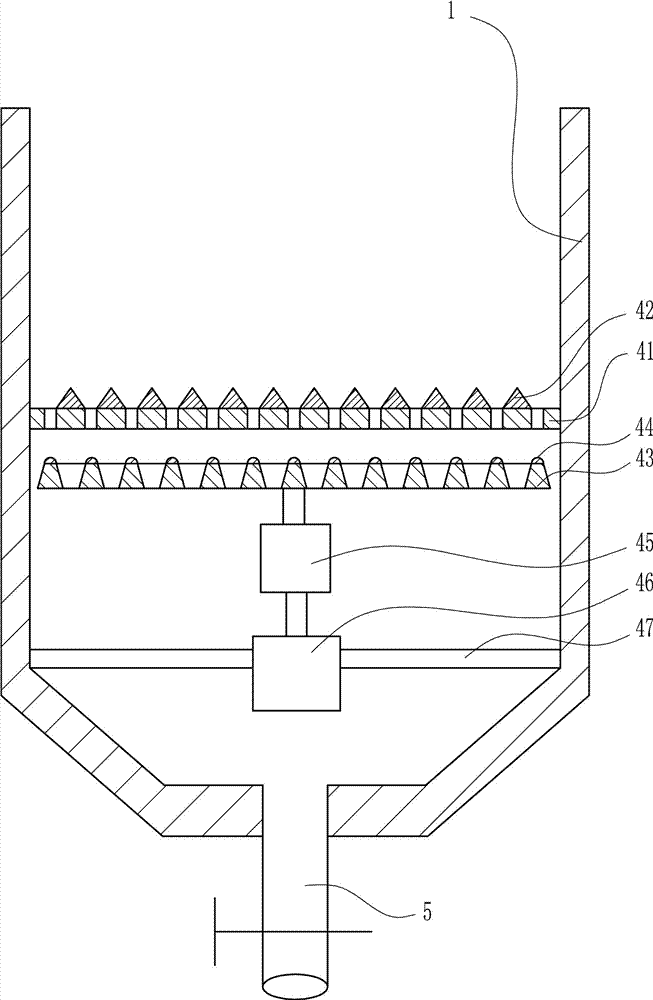

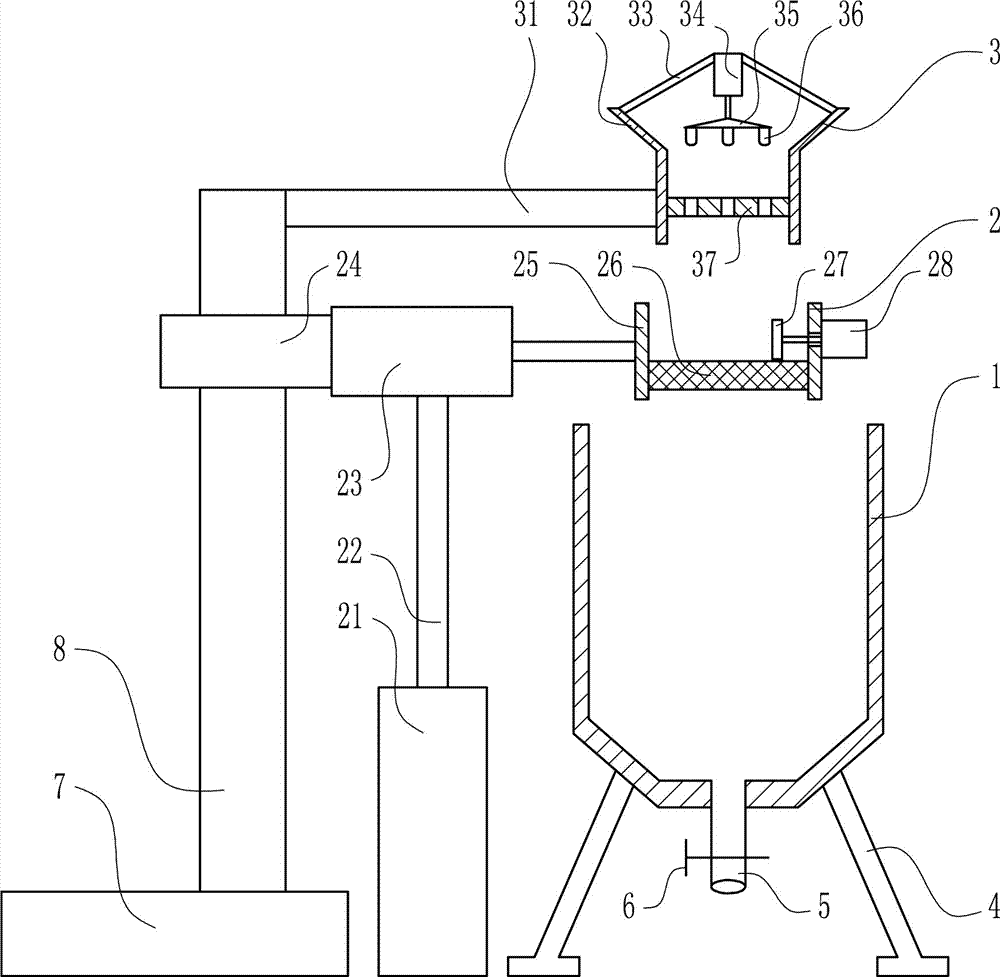

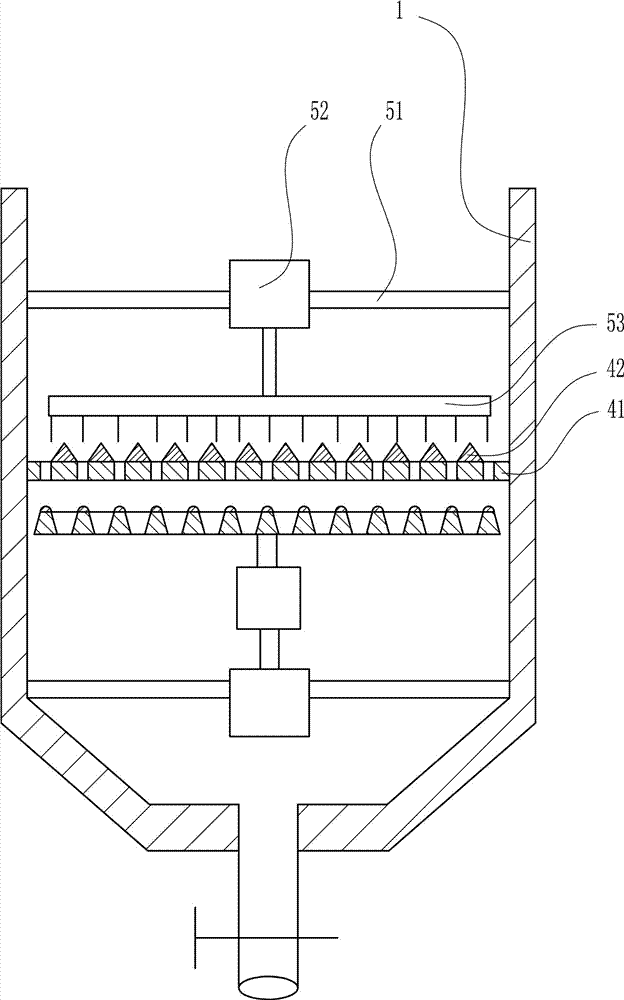

[0027] A high-speed screening and crushing device for rare earth carbonate, such as Figure 1-3 As shown, it includes a cylinder 1, a screening device 2, a feeding device 3, a leg 4, a discharge pipe 5, a valve 6, a base 7 and a fixed column 8; the top of the cylinder 1 is open, and the A sieving device 2 is arranged above the body 1, a feeding device 3 is arranged above the sieving device 2, and outriggers 4 are arranged symmetrically at the bottom of the cylinder 1. The walls are connected by welding, and a discharge pipe 5 is arranged directly below the cylinder body 1. The upper end of the discharge pipe 5 is connected to the bottom of the cylinder body 1 by welding, and a valve 6 is arranged on the discharge pipe 5. A base 7 is provided on the left side of the cylinder body 1 , the top of the base 7 is connected to the lower end of the fixed column 8 by welding, and the screening device 2 and the feeding device 3 are connected to the fixed column 8 .

Embodiment 2

[0029] A high-speed screening and crushing device for rare earth carbonate, such as Figure 1-3 As shown, it includes a cylinder 1, a screening device 2, a feeding device 3, a leg 4, a discharge pipe 5, a valve 6, a base 7 and a fixed column 8; the top of the cylinder 1 is open, and the A sieving device 2 is arranged above the body 1, a feeding device 3 is arranged above the sieving device 2, and outriggers 4 are arranged symmetrically at the bottom of the cylinder 1. The walls are connected by welding, and a discharge pipe 5 is arranged directly below the cylinder body 1. The upper end of the discharge pipe 5 is connected to the bottom of the cylinder body 1 by welding, and a valve 6 is arranged on the discharge pipe 5. A base 7 is provided on the left side of the cylinder body 1 , the top of the base 7 is connected to the lower end of the fixed column 8 by welding, and the screening device 2 and the feeding device 3 are connected to the fixed column 8 .

[0030] The screeni...

Embodiment 3

[0032] A high-speed screening and crushing device for rare earth carbonate, such as Figure 1-3 As shown, it includes a cylinder 1, a screening device 2, a feeding device 3, a leg 4, a discharge pipe 5, a valve 6, a base 7 and a fixed column 8; the top of the cylinder 1 is open, and the A sieving device 2 is arranged above the body 1, a feeding device 3 is arranged above the sieving device 2, and outriggers 4 are arranged symmetrically at the bottom of the cylinder 1. The walls are connected by welding, and a discharge pipe 5 is arranged directly below the cylinder body 1. The upper end of the discharge pipe 5 is connected to the bottom of the cylinder body 1 by welding, and a valve 6 is arranged on the discharge pipe 5. A base 7 is provided on the left side of the cylinder body 1 , the top of the base 7 is connected to the lower end of the fixed column 8 by welding, and the screening device 2 and the feeding device 3 are connected to the fixed column 8 .

[0033] The screeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com