Three-proofing filtering element

A filter element and paper core technology, which is applied in the field of three-proof filter element, can solve the problems of insufficient impact resistance, anti-explosive pulse and resistance to harsh environmental conditions, inability to meet air filtration, and unsuitable filter elements, and achieve strong chemical resistance. , high hardness, scientific and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

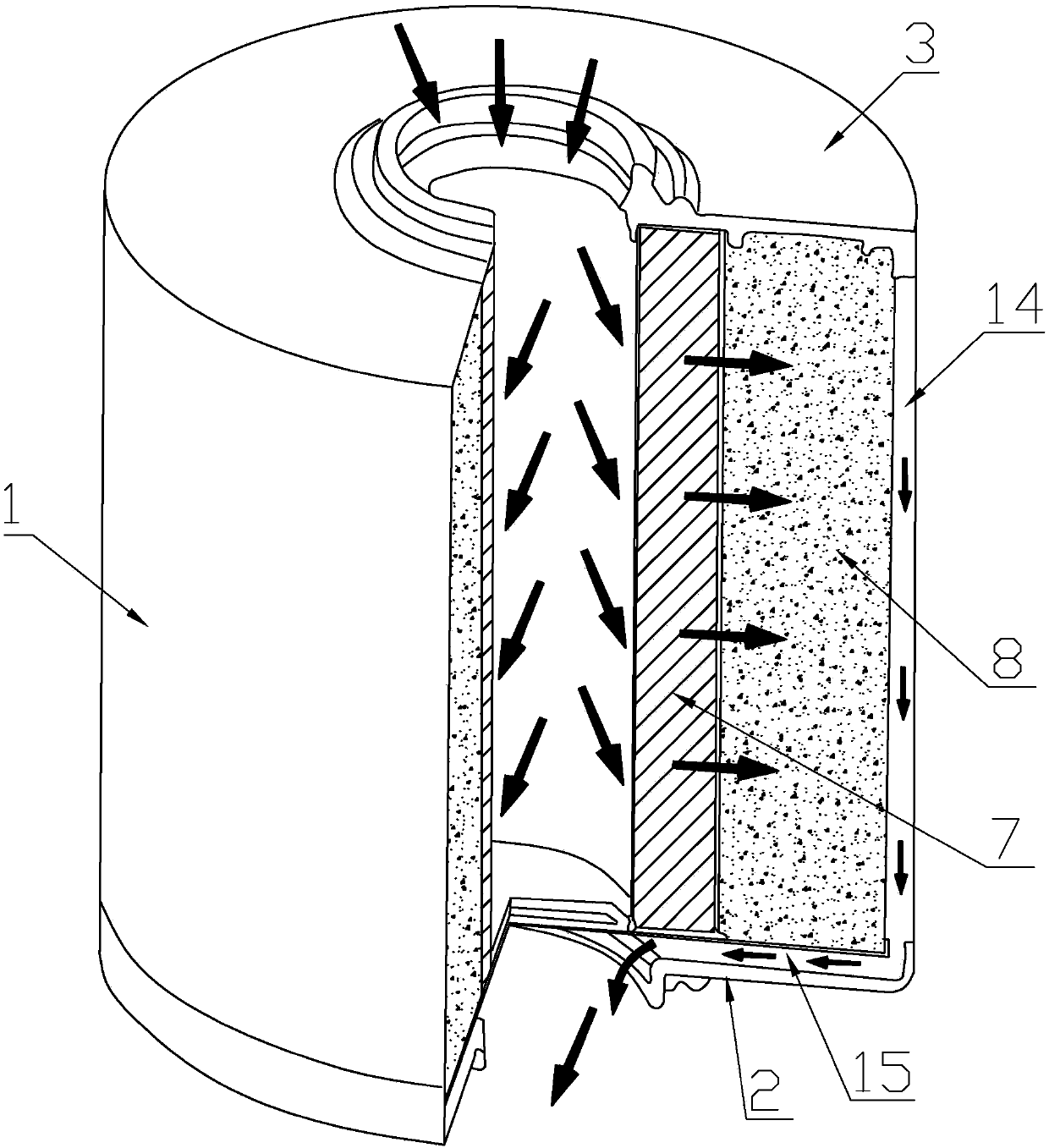

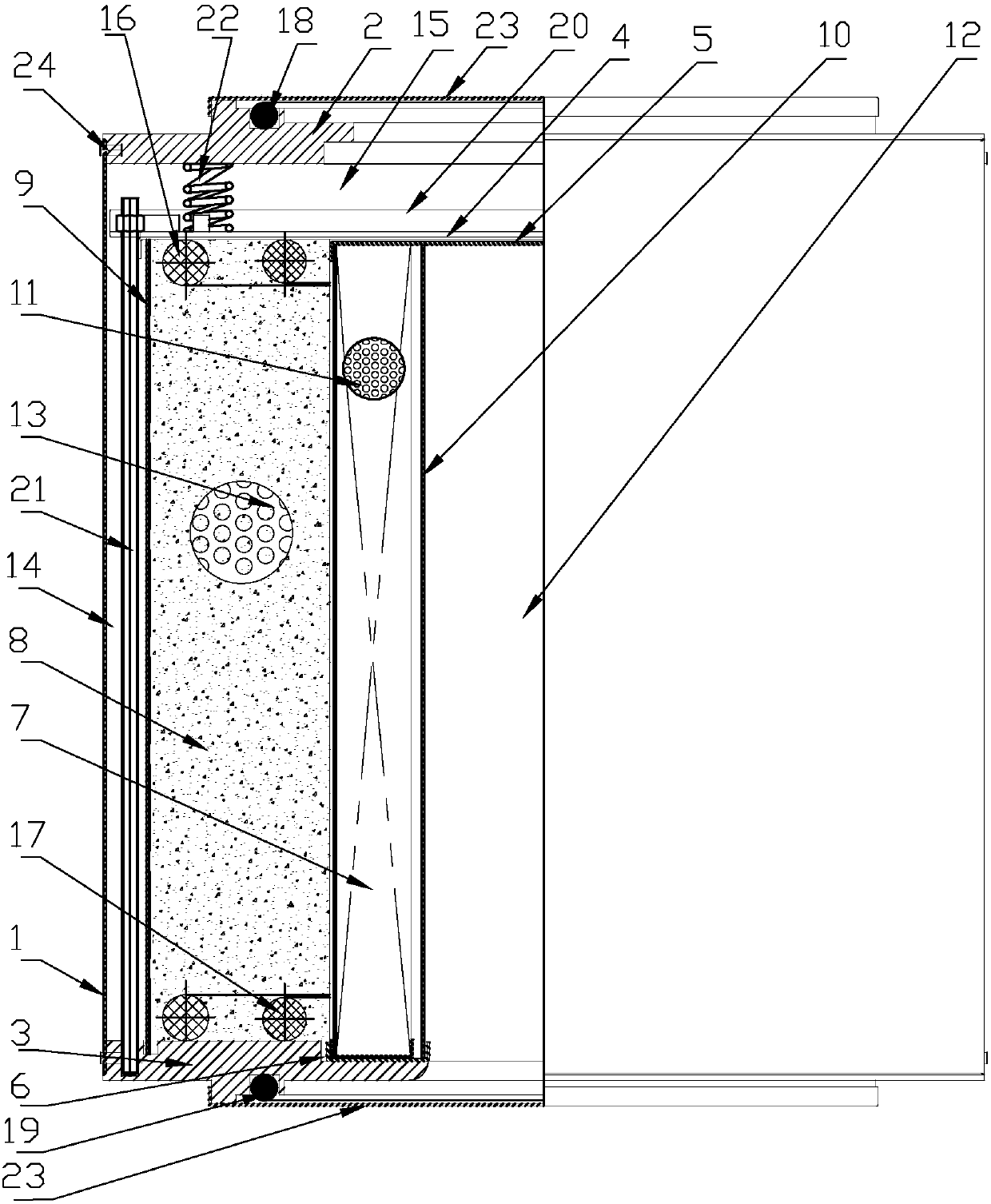

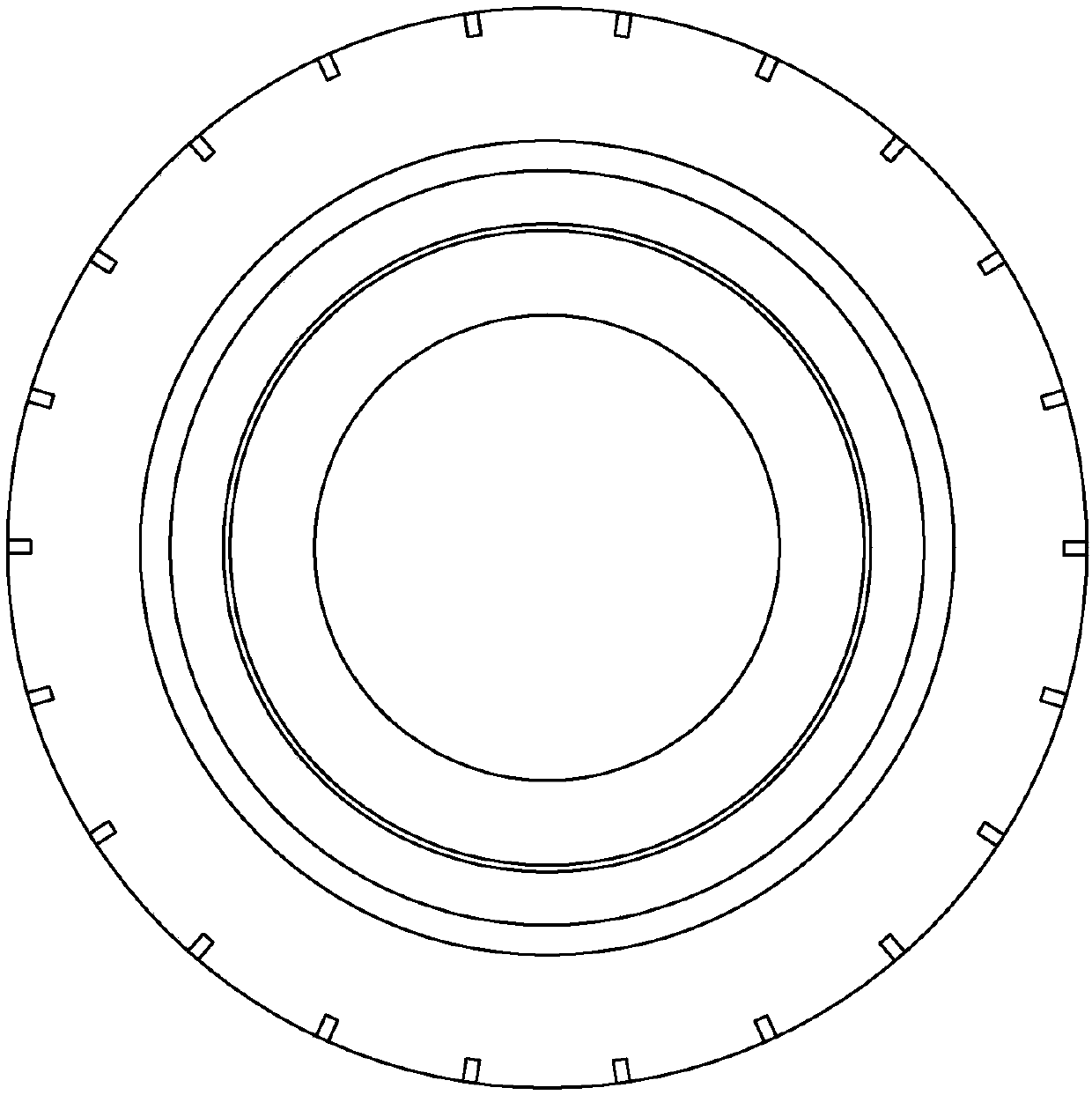

[0024] see Figures 1 to 9 The three-proof filter element provided in this embodiment includes a metal outer barrel 1, an upper cover plate 2, a lower cover plate 3, a metal inner cover 4, a paper core upper end cover 5, a paper core lower end cover 6, a paper core 7, activated carbon particles Layer 8, outer nylon mesh 9, inner nylon mesh 10, paper core outer protective mesh 11, paper core inner protective mesh 12 and carbon particle layer outer protective mesh 13; the paper core 7 and the activated carbon granular layer 8 are stacked adjacently The cylindrical structure, the paper core 7 is located inside, and the activated carbon particle layer 8 is located outside; the paper core upper end cover 5 is a circular sealing cover, which is arranged on the paper core 7 upper end, and the paper core 7 upper end and the paper core hollow part The ports are all sealed; the lower end cover 6 of the paper core is an O-shaped hollow cover, which is arranged at the lower end of the pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com